Unlocking The Potential Of Digital Pressure Transmitters

By Matt Verket

The adoption of digital technology has significantly transformed industries across the globe, including pressure transmitters and other sensors and measurement devices. Traditional analog devices, once the industry standard, are increasingly being replaced by digital solutions.

Digital communication protocols like CANopen are playing a key role in this transition, enabling seamless communication and enhanced functionality in modern systems.

This shift calls for engineers to assess whether digital pressure transmitters are the best fit for their specific applications.

Where Are Pressure Transmitters Used?

Pressure transmitters are essential for converting pressure into electrical signals, enabling precise monitoring and control across various industries.

They are widely used in fluid flow regulation, hydraulic systems, and process optimization in sectors like manufacturing, energy, and water treatment. Construction equipment, automotive systems, and robotics also depend on pressure transmitters for efficient operation and safety.

In the oil and gas industry, they ensure accurate pressure monitoring in pipelines, offshore drilling, and refinery equipment, while mining applications rely on them for heavy machinery diagnostics and safety systems.

Utilities and power grids use transmitters for power generation monitoring and infrastructure diagnostics. In aerospace, defense, and research, they support test equipment, harsh environment operations, and flexible sensor deployment.

Designed to withstand extreme conditions like temperature fluctuations, corrosion, and vibrations, pressure transmitters ensure reliability and optimal system performance across all these demanding environments.

Advantages Of Digital Pressure Transmitters

Both digital and analog pressure transmitters fulfill the same core purpose, but digital systems bring significant advantages that make them a better choice in many applications.

1. Reduced Wiring Complexity

Unlike analog devices, which require individual wiring connections to a controller, digital transmitters using protocols like CANopen allow multiple sensors to communicate over a single shared line. This "daisy chain" setup dramatically reduces wiring complexity, streamlines installation, and lowers costs.

For example, in an automotive context, a 12-cylinder diesel engine might have multiple sensors on each engine bank. With digital systems:

- Physical wiring is significantly reduced.

- Installation is simplified.

- Potential points of failure are minimized.

- The system becomes more compact and efficient.

The base CANopen standard supports up to 255 devices on a single communication line, while CAN FD (Flexible Data-rate) expands this capacity even further, accommodating more sensor nodes.

2. Enhanced Functionality

Digital pressure transmitters leverage communication protocols to deliver more functionality than analog devices. With CANopen, sensors can transmit multiple data points simultaneously, such as pressure and temperature readings, enabling richer and more comprehensive monitoring and data analysis.

3. Remote Monitoring and Diagnostics

For operators and maintenance teams, digital transmitters allow remote configuration, diagnostics, and troubleshooting, improving safety by reducing the need for physical interaction with dangerous machinery. These systems save significant time and costs by eliminating the need for employees to climb five-story-tall mining dump trucks or access difficult locations.

Digital systems enable operators to diagnose and resolve issues remotely, enhancing efficiency and minimizing downtime. They also facilitate timely, proactive remote support from device manufacturers, further optimizing system performance.

4. Flexibility and Reconfigurability

A key advantage of digital pressure transmitters is their adaptability. These sensors can be easily reprogrammed to suit new applications, reducing the need for a large inventory of specialized sensors and improving operational flexibility.

They allow for network-wide reprogramming with minimal effort and enable adjustments to sensor characteristics, such as modifying measurement thresholds to focus on critical pressure drops.

Digital pressure transmitters can quickly adapt to new testing scenarios, making them ideal for environments like laboratories or automotive manufacturing quality assurance testing. For example, instead of sourcing a specific replacement sensor for a new application, existing sensors can be reprogrammed with updated parameters, saving both time and resources.

CANopen And IO-Link: Comparing Two Key Digital Protocols For Pressure Transmitters

When it comes to digital protocols for pressure transmitters, two of the most commonly used options are CANopen and IO-Link. While CANopen has achieved widespread adoption in industrial automation, it’s important to note that it’s not the only protocol available. Each protocol offers unique strengths depending on the specific application requirements.

What is CANopen?

CANopen is a well-established and highly reliable protocol based on the Controller Area Network (CAN) bus. It supports real-time communication, advanced network management, and standardized device profiles, ensuring interoperability across manufacturers. Known for its scalability, robustness, and high-speed capability (up to 1 Mbps), CANopen is a trusted choice for demanding industrial applications such as motion control, heavy machinery, and medical equipment.

Standardized by the CAN in Automation (CiA) organization, CANopen has achieved widespread adoption and has a strong track record that ensures its continued relevance in industrial automation. Its long-term reliability and performance make it a future-ready solution for complex industrial networks.

What Is IO-Link?

IO-Link is a point-to-point communication protocol specifically designed for smart sensors and actuators. It enables bidirectional data exchange for process information, diagnostics, and parameterization, making it particularly well-suited for Industry 4.0 initiatives and smart factory environments.

With a strong emphasis on simplicity, cost-effectiveness, and actionable insights, IO-Link provides an efficient solution for connecting individual devices. It supports predictive maintenance and condition monitoring, helping to optimize system performance and reduce downtime.

Choosing The Right Protocol

While CANopen remains one of the most widely used protocols for industrial networks due to its scalability and robustness, IO-Link provides an alternative that prioritizes simplicity and smart device integration. Both protocols have distinct strengths, and the choice depends on the specific needs of your application.

Key Components Of A Digital Pressure Transmitter

Digital pressure transmitters rely on two critical components: the pressure sensor and an Application-Specific Integrated Circuit (ASIC). Together, these components work seamlessly to measure pressure accurately and provide reliable outputs.

Pressure Sensor

The pressure on the sensor is applied via the pressure connection (also called the process connection). The pressure sensor is equipped with a thin-film-on-steel cell, where resistance bridges are applied as a thin film to a steel sensing element. When pressure is applied, the membrane deforms, causing resistors at precise points to compress or stretch, which alters their values and generates an electrical signal. However, this raw signal is inherently non-linear and affected by temperature, requiring correction for accuracy.

Application-Specific Integrated Circuit (ASIC)

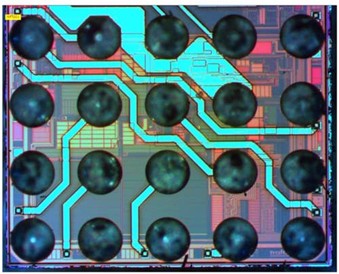

The ASIC processes the raw signal from the pressure sensor, ensuring accurate, linear, and temperature-independent measurements. It amplifies, corrects, and normalizes the signal into a standardized output. During calibration, the transmitter is tested under various pressures and temperatures to determine correction values, which are stored in the ASIC. This enables the transmitter to deliver highly reliable measurements across its entire operating range.

The ASIC contains millions of circuits on an area of about 2.5 x 2.5 millimeters. The solder points (grey-blue circles in the picture) provide the contact between the chip and the electronics of the pressure transmitter.

The Importance Of A Well-Integrated System

Achieving precision, durability, and reliability in pressure transmitters depends on the seamless integration of these components. Trafag, a leader in high-accuracy pressure transmitters, addresses this need by designing and manufacturing both its Application-Specific Integrated Circuits (ASICs) and pressure sensors entirely in-house.

- Optimized Performance: Custom-designed ASICs ensure perfect compatibility with corresponding pressure sensors, minimizing performance issues and maximizing measurement accuracy.

- Enhanced Reliability: By designing components together, environmental stresses like extreme temperatures and vibrations are anticipated and mitigated, ensuring long-term durability.

- Streamlined Production: Manufacturing both ASICs and sensors in-house allows for strict quality controls, reducing variability and ensuring consistent performance across all units.

- Tailored Solutions: Co-development enables the creation of customized solutions for specific industrial needs, whether for precise laboratory measurements or robust performance in heavy machinery.

- Resilient Supply Chain: Producing key components internally reduces reliance on external suppliers, ensuring a steady supply chain and maintaining high-quality standards.

Unlock New Possibilities

Digital pressure transmitters, particularly those using CANopen protocols, offer significant advantages over analog systems. They reduce wiring complexity with shared communication lines, enhance functionality by transmitting multiple data points simultaneously, and enable remote monitoring, diagnostics, and configuration for improved safety and efficiency. Additionally, digital systems provide flexibility, allowing easy reprogramming and adaptability.

Matt Verket is Application Engineer and Product Manager at Trafag Inc