The Role Of Turbine Flow Meters In Wastewater Treatment Plants

Why Flow Data Is the Lifeline of Wastewater Facilities

By Mark Weiss

Wastewater treatment plants are responsible for protecting waterways, communities, and ecosystems from harmful contaminants. To do this effectively, plant operators rely on accurate flow data at every stage of the process. Flow measurement is not just a technical detail. It provides the foundation for compliance reporting, process optimization, and long-term operational efficiency.

When flow measurement is inaccurate, the consequences are significant. Plants may underdose or overdose chemicals, overestimate or underestimate capacity, or fail to meet environmental discharge requirements. Regulatory fines, increased operating costs, and even environmental damage can follow. Because of this, the instruments that measure flow are among the most important tools inside a treatment plant. Turbine flow meters, with their strong track record of accuracy and reliability, are often the choice for applications where precision matters most.

Key Applications For Turbine Flow Meters In Wastewater Treatment

Wastewater plants are made up of a series of interconnected processes, each one dependent on accurate data. Turbine flow meters can be installed at several stages to provide operators with real-time, trustworthy flow information.

Influent Monitoring

The very beginning of the treatment process involves monitoring raw wastewater as it enters the plant. Measuring influent flow rates allows operators to understand the volume of material coming into the system and adjust processes accordingly. Turbine meters are well suited for this application when solid content is manageable, providing consistent readings that help set the pace for treatment.

Process Control Between Stages

As water moves from one stage of treatment to another, flow rates must be carefully controlled to ensure each step functions as designed. Whether it is primary clarification, biological treatment, or filtration, turbine flow meters can help maintain balanced and steady flows through the system. This prevents overload and ensures efficiency in downstream processes.

Chemical Dosing and Disinfection

Accurate chemical dosing is one of the most sensitive areas of wastewater treatment. Adding too little disinfectant or coagulant may compromise water quality, while overdosing increases chemical costs and can create safety risks. Turbine meters excel here because of their high accuracy and repeatability, allowing operators to precisely meter the amount of chemical being added to the system.

Effluent Monitoring and Compliance

The final stage of a wastewater treatment plant involves measuring the flow of treated effluent before it is discharged. This data is often required for compliance with state and federal regulations, making accuracy non-negotiable. Turbine meters provide reliable measurements that give municipalities and industrial facilities confidence in their reporting while ensuring compliance with discharge permits.

Advantages Of Turbine Flow Meters In Wastewater Applications

Turbine flow meters have remained a preferred choice for many plants despite the introduction of newer flow technologies. Their advantages are well aligned with the needs of wastewater operations.

High Accuracy and Repeatability

Turbine meters offer tight accuracy ranges, often within ±0.5% of reading, with repeatability as fine as ±0.25%. This ensures that when a process is repeated under the same conditions, the meter will consistently return the same result. For critical applications like chemical dosing and effluent monitoring, this level of accuracy reduces risk and builds confidence.

Wide Flow Range

Turbine meters can measure flow across a broad range of velocities, which is useful in wastewater plants where flow volumes fluctuate depending on time of day, season, or unexpected surges. Operators can trust the meter to perform reliably whether flows are low during overnight hours or high during stormwater events.

Durable Design

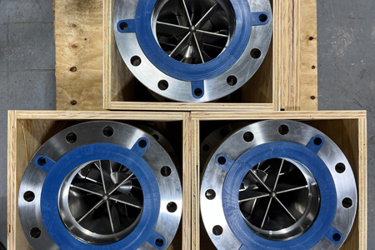

Turbine meters are engineered to perform under challenging conditions. With the right material selection, they can handle corrosive wastewater streams or aggressive cleaning chemicals without losing accuracy. Their mechanical design allows them to maintain calibration and withstand years of continuous service with minimal maintenance.

Cost-Effectiveness

Compared to some newer technologies, turbine meters are often more affordable while still delivering the performance required for wastewater applications. For municipalities with limited budgets, turbine meters strike a balance between accuracy, reliability, and cost.

Factors To Consider Before Choosing Turbine Flow Meters

While turbine meters deliver significant benefits, wastewater facilities need to evaluate a few considerations to ensure the technology is the right fit for their application.

Clean Liquid Requirement

Turbine meters perform best in relatively clean liquid streams. Wastewater influent with high solids content, sludge, or grit can cause wear and reduce accuracy. In these cases, meters may need to be installed in cleaner sidestreams or paired with strainers to protect the rotor.

Regular Maintenance and Calibration

Like any precision instrument, turbine meters require periodic calibration and maintenance to perform at their best. Plant operators should establish a routine schedule to verify meter accuracy and inspect for wear. This ensures long-term reliability and protects compliance reporting.

Proper Sizing and Material Selection

Choosing the correct meter size is critical. A meter that is too large may not register low flows accurately, while a meter that is too small could be damaged by high volumes. Materials of construction also matter. Stainless steel or corrosion-resistant alloys are common choices for wastewater plants to handle harsh conditions.

Comparing Turbine Meters With Other Flow Technologies

With a variety of flow measurement technologies available today, it is important to understand how turbine meters compare to other options.

Electromagnetic Flow Meters

Mag meters are popular in wastewater treatment because they can handle liquids with high solids content and do not have moving parts. However, they tend to be more expensive than turbine meters, and for applications with relatively clean water or chemical dosing, turbines may provide equal accuracy at a lower cost.

Ultrasonic Flow Meters

Ultrasonic meters use sound waves to measure flow and are highly accurate in both clean and dirty water. They also have no moving parts and require less maintenance. The tradeoff is higher upfront cost and greater sensitivity to installation conditions, making turbine meters the more economical choice in many cases.

Coriolis Flow Meters

Coriolis meters provide extremely high accuracy and can measure both mass flow and density. They are well suited for specialty applications but are typically cost-prohibitive for widespread use in wastewater treatment. Turbine meters remain a practical option for plants that need accuracy without overspending.

Real-World Benefits Of Turbine Flow Measurement

The impact of turbine flow meters goes beyond technical specifications. In real-world wastewater treatment facilities, they have been instrumental in improving performance, reducing costs, and ensuring compliance.

For example, municipalities using turbine meters for chemical dosing have reported significant reductions in chemical costs due to more precise metering. Plants that rely on turbine meters for effluent monitoring gain peace of mind knowing that their compliance data is accurate and defensible during audits. Industrial facilities with wastewater discharge permits often use turbine meters to track flow for billing purposes, avoiding disputes with local utilities.

These outcomes highlight the role turbine meters play in keeping wastewater treatment plants efficient, compliant, and financially sustainable.

Building Reliable Systems With Turbine Flow Meters

Wastewater treatment plants depend on accurate flow data to function properly. From monitoring to final discharge, every step requires trustworthy measurements that inform decisions and keep processes under control. Turbine flow meters deliver the accuracy, repeatability, and durability that operators need while offering a cost-effective alternative to some of the newer technologies on the market.

By carefully considering application conditions, maintenance needs, and proper sizing, facilities can integrate turbine meters into their operations with confidence. The result is better compliance, reduced costs, and a stronger foundation for protecting the environment and public health.

Mark Weiss is an industrial marketing strategist specializing in flow measurement. At Turbines, Inc., he drives targeted campaigns for turbine meters and other technologies across technical industries, translating complex specs into clear value for engineers, procurement teams, and decision-makers in process industries.