SWAN Corner: How Advanced Process Controls Empower Operators, Enhance Effluent Quality, Save Energy, And Reduce N2O And CO2 Emissions At Wastewater Treatment Plants

By Otto Icke, Ellen van Voorthuizen, Frank van de Grootevheen, Sietske Riemersma, Ralph Bröcheler, and Leon Verhaegen

Environmental, regulatory, and technological shifts are putting pressure on European wastewater utilities.

Climate change impacts are stretching wastewater infrastructure to its limits. At the same time, legislation is also evolving. Effluent requirements are becoming stricter, partly due to the Water Framework Directive requiring all water bodies to achieve a good ecological and chemical status. And with more advanced pollutants entering water systems, their removal from wastewater before it’s discharged is both crucial and complex.

Water authorities also need to find ways to reduce energy and chemical consumption to lower their costs and emissions. Regulations are tightening around acceptable carbon dioxide (CO2) emissions, and many wastewater utilities have already set targets to achieve carbon neutrality by 2030. But now regulations for other greenhouse gas emissions are also beginning to emerge.

Nitrous oxide (N₂O) is emitted during the nitrogen removal process and is approximately 265 times more potent than CO₂ — making up roughly two thirds of the greenhouse gasses emitted by wastewater treatment plants (WWTPs).

There is already anticipated legislation for N2O emissions in Denmark, with other countries likely to follow. Dutch water authorities have set an ambitious goal of achieving climate neutrality by 2035, but this will be unattainable without a significant reduction in N₂O emissions. And, while legislation may take time to fully implement, putting a plan in place to reduce emissions now is imperative if wastewater utilities want to meet these regulations and ambitions as they come into effect.

To meet this growing number of regulatory, environmental, and strategic objectives, WWTPs are having to rely on increasingly complex infrastructure. With stricter effluent requirements and a greater desire to reuse substances removed from wastewater, the number of processes wastewater undergoes is also growing.

In addition, an ageing workforce puts operators at risk of losing access to key knowledge and experience as their most experienced workers approach retirement. Utilities need to find ways to facilitate greater knowledge sharing, attract the employees of tomorrow and empower them with the technological capabilities they need to meet the complex demands of modern water treatment.

Technology like advanced process control systems doesn’t just attract the talent of tomorrow, it can also streamline operations, create opportunities to lower costs and emissions, and ensure effluent quality meets the highest standards. Research also indicates that implementing an appropriate control strategy can help reduce N₂O emissions.

What Are Advanced Process Controls, And How Are They Applied?

Advanced process control (APC) systems use a holistic approach that incorporates both artificial intelligence and domain knowledge. They support the workforce with predictive insights and automated controls so they can focus on driving up effluent quality in an energy and cost-efficient way while reducing excess CO2 and N2O emissions.

By comparison, local controllers are often reactive rather than proactive and operate without any insight into what is likely to happen in the near future. This means every adjustment in response to changes in conditions is only made as it becomes necessary.

A major benefit of APC systems is that they offer advanced capabilities like predictive control. The algorithm can anticipate near-future conditions, reducing the likelihood of excessive reactions to immediate fluctuations. That means it only needs minor adjustments for real-time measurements.

Several factors that alter conditions at a plant are predictable, for example the daily dry weather flow (or load) pattern. A predictive controller can then determine when flow (or load) to the plant will increase and when more aeration will be necessary.

By uncovering these typical process needs, the predictive controller only needs to make slight adjustments for variations in load. This makes it easier to maintain optimal and stable operations and, consequently, improves nutrient removal efficiency. As a result, the system can lower nutrient concentrations in the effluent, avoid excessive aeration, and achieve substantial energy savings. APC systems can also use predictive controls to automate areas of process operations to actively target these benefits.

Local controllers can also have different ways of working, but in an advanced system, decisions are based on a data-driven approach. Some APCs use black box neural networks which require a huge amount of data to determine setpoints. However, those setpoints can be difficult to trace back to their source. And when the circumstances significantly change, retraining can be difficult, since enough data must be collected to execute successful retraining.

There is another approach though. By using a combination of data, relationships, and domain principles to establish setpoints, operators can create a reliable prediction that can be transparently traced back to its source. This requires much less data — potentially just a few weeks’ worth — to establish an initial reading, and is much more adaptable, and quicker to retrain itself, as the circumstances evolve.

With a system like this, operators can opt to take control and manually disapprove data from the system for days that have deviated from the norm and could influence any learned patterns. And, once systems are fully up and running, they can automatically determine any anomalous days to disregard. The operators can still intervene when needed, but they can confidently rely on the system to run autonomously in most situations.

The Benefits Of Advanced Process Controls

APC technologies are invaluable for achieving high-quality effluent, in some cases even supporting water reuse, and maintaining compliance as regulations evolve.

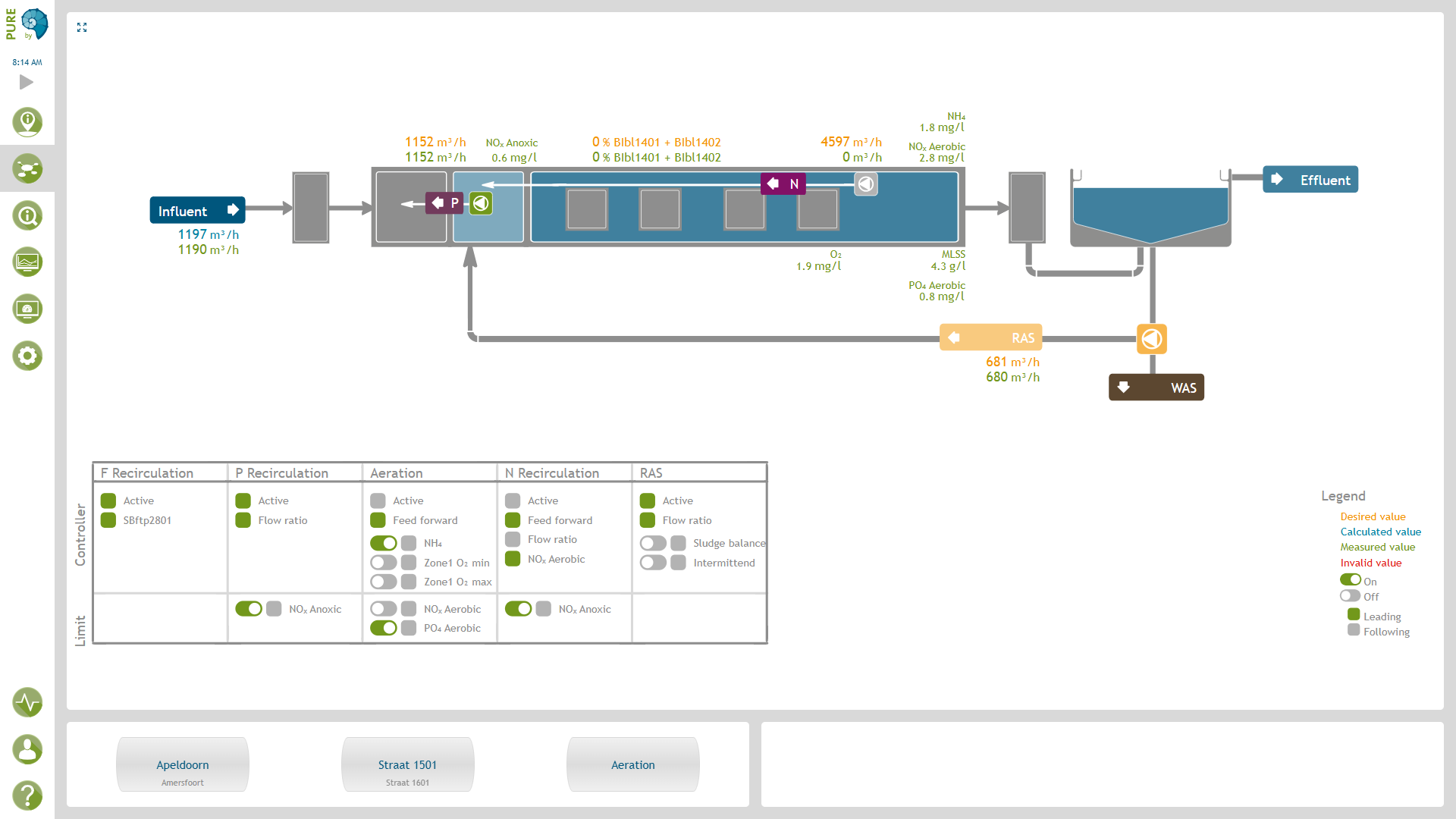

APCs provide real-time monitoring — continuously checking variables like nutrient and dissolved oxygen levels, and flow rates. They can then automatically adjust aeration, recirculation, chemical dosing, and return and surplus activated sludge to maintain optimal conditions. Leveraging a data-driven baseline setpoint allows for subtle, intelligent adjustments that keep control stable while dynamically responding to real-time conditions.

By using APCs to fine-tune operations, utilities can reduce energy consumption — particularly in energy-intensive processes like aeration. Plus, advanced controls help maintain the conditions needed for the efficient removal of nutrients like nitrogen and phosphorus without overaerating or overdosing chemicals.

APCs can also detect anomalies in equipment performance, so wastewater treatment teams can carry out proactive maintenance at the most convenient time. And with an automatic log of all system data, compliance reporting is simplified, too.

In summary, APCs and monitoring can improve effluent quality, energy efficiency, and emissions reduction. Plus, they help ensure stable and reliable wastewater treatment process operations with:

- A virtual operator for 24/7 optimal stable operation, supporting and empowering the whole team

- Energy saving and chemical consumption reduction opportunities

- Effluent quality enhancements

- CO2 and N2O emissions reductions

- Reduction in capital and operational expenses

What Advanced Process Control Systems Can Look Like In Practice

WWTP Apeldoorn

Water Authority Vallei en Veluwe has been an early adopter of APCs at its WWTPs. In doing so, it has addressed a variety of issues including recent concerns about N₂O emissions. Water Authority Vallei en Veluwe now uses APCs for the water line at nine of its plants, the influent flow to four of its plants, and for sludge dewatering at one plant.

One plant where Water Authority Vallei en Veluwe has implemented an APC for the water line is at WWTP Apeldoorn. This plant faced significant nitrogen load challenges, partly due to return flows from the sludge line. This made stable process management complex and added significant challenges around meeting effluent standards for total nitrogen.

In addition, a study revealed the plant was frequently experiencing over-aeration, which negatively impacted total nitrogen levels. Over-aeration is also a critical factor for energy consumption, accounting for roughly half of the total energy consumption of a WWTP. Due to the high nitrogen load, the plant was also at a high risk of producing significant N₂O emissions.

In 2016, Water Authority Vallei en Veluwe implemented Aquasuite Pure, an APC by Haskoning, on both lanes of its WWTP Apeldoorn, incorporating various controllers for aeration and internal recirculation.

These controls use self-learning algorithms to accurately estimate the required base setpoint, so only minor adjustments are needed to compensate for fluctuations in actual measured values.

One key advantage of this approach is that it gives operators the ability to anticipate near-future states rather than forcing them to continuously react to the current state. This delivers more optimal and stable waterline operation and reduces incidents of over-aeration — saving significant energy and enhancing the nitrogen removal process. And this ultimately results in reduced N₂O emissions and the total nitrogen in the effluent.

In addition, the algorithms continue to learn and anticipate, providing a robust solution that adapts with a changing wastewater landscape and eases the workload of process operators.

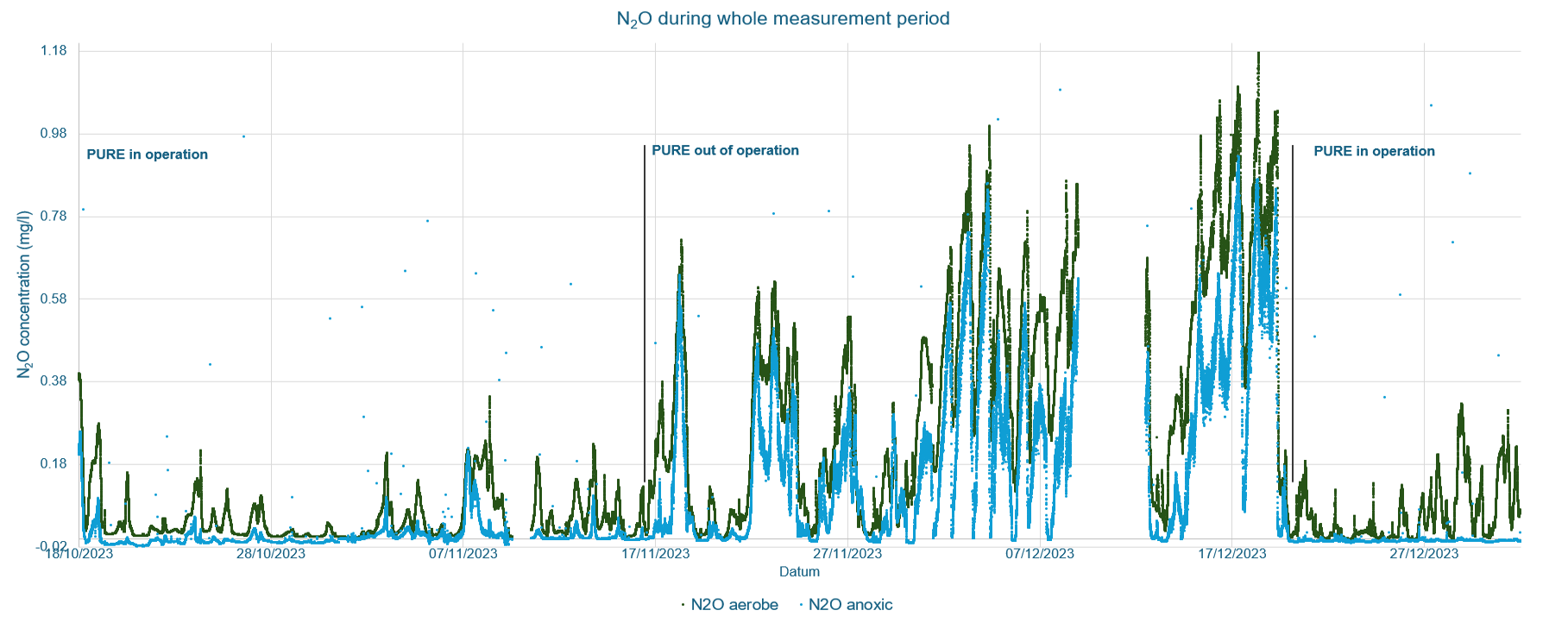

The APC has been in continual operation at WWTP Apeldoorn since mid-2016, except for periods of major maintenance. However, in the autumn of 2023, communication failures led to its temporary shutdown. In total, the APC was switched off for over a month during a period of approximately 2½ months.

This created an opportunity to learn more about the system, as it allowed for comparison between the APC and local control. This was particularly valuable as it coincided with the Dutch N2O acceleration program, a measurement campaign to map N₂O emissions.

It was proven that N₂O concentrations are significantly lower with the APC in operation compared to using a local controller. Converted to emission factors, the average N₂O emissions with the APC in operation appears to be approximately 90% lower.

And that’s not the only benefit WWTP Apeldoorn measured. With the APC in operation, total dissolved nitrogen, orthophosphate, and energy consumption were approximately 8%, 22%, and 8% lower, respectively, compared to when the APC was not in operation.

These figures demonstrate the significant value that can be unlocked by optimising existing assets through the application of an APC.

In addition to the tangible results for effluent quality, energy savings, and emission reduction, APCs ensure stable and reliable operation. This means process operators can use their valuable time more effectively. Plus, as a self-learning system, APCs can rely on predictions and compensate any failures of measuring instruments.

Consequently, process operators are fully empowered by the support of the APC. The system remains secure and controlled with the best alternative setpoint, minimising the need for manual intervention.

Better effluent quality and N2O emission reduction go hand in hand

“Aquasuite Pure is a reliable controller, which provides good and stable operations due to accurate DWF predictions. With very limited adjustments, good effluent quality is achieved and N2O emissions are reduced. Even in unusual situations, such as when measuring equipment fails, Aquasuite Pure provides excellent results by using the learned predictions.”

- Frank van de Grootevheen, Process technologist at Waterschap Vallei & Veluwe

Waterschap Limburg

Water Authority Limburg faced stricter effluent standards, increasingly complex infrastructure, and ambitious targets to reduce energy and chemical consumption. So, it applied an APC, Aquasuite Pure, to enhance its ability to stabilise effluent quality, lower energy consumption, and reduce variability in operations.

In 2024, Water Authority Limburg commissioned the APC across all three lanes of the water line at WWTP Susteren. It included controllers for aeration and internal recirculation, among other things, which use self-learning algorithms to accurately determine baseline setpoints. This means minimal modifications are required to meet desired targets.

The APC was evaluated over an 11-week period in 2025. This trial used five days of APC operation, followed by a transition day, and then five days using PLC matrix control — ensuring both control strategies were tested under comparable conditions.

Water Authority Limburg discovered that the APC substantially enhances both effluent quality and aeration efficiency. Although nitrate levels were 3% higher with the APC, Water Authority Limburg saw a major improvement in overall nitrogen conversion through both nitrification and denitrification processes. Compared to PLC matrix control, APC achieved:

- 39% reduction in ammonium concentrations

- 10% reduction in total dissolved nitrogen

- 24% reduction in orthophosphate concentrations

The APC also delivered a 16% reduction in air flow, which led to significant energy savings — equivalent to an annual decrease of approximately 130 tons of CO2 emissions.

Water Authority Limburg also experienced increased process stability as a result of implementing the APC. It reported that with the APC, process performance is much less dependent on individual process operators.

Effluent quality, energy efficiency, emissions reduction, and stable and reliable 24/7 plant operation

“The process of implementing and working with Pure has provided us with new insights into the functioning of the treatment plant and exploring the boundaries of the process. Moreover, Pure has made it easier for us to immediately apply these insights to achieve better process results.”

- Ralph Bröcheler, Process technologist at Waterschap Limburg

Advanced Process Control For Effluent Quality, Energy Savings, And Emission Reduction

As effluent requirements grow and more legislation comes into force around emissions, you’ll need to make sure your water treatment processes are stable, well managed, and compliant. APCs can be invaluable tools to help you meet evolving demands from environmental bodies, policymakers, and your workforce — propelling you into a sustainable and modern future for wastewater management.

So take a look at your operational processes. If you're facing rising operational costs or struggling with effluent quality and carbon neutrality, it’s worth considering how APCs could support you. They offer a proven way to reduce greenhouse gas emissions and energy and chemical consumption, while enhancing overall effluent performance. Plus, APCs ensure stable and reliable plant operation and empower operators to meet ambitious efficiency and effluent quality targets.

About the Authors:

Otto Icke, Product Manager Aquasuite Pure and Mine at Haskoning, graduated from Wageningen University in August 2006 with a specialisation in water management. He has been employed at Haskoning since 2007, and in his current role provides expertise around the advanced monitoring and control for water and sludge at wastewater treatment plants.

Ellen van Voorthuizen, Senior Consultant Wastewater Technology at Haskoning, graduated from Wageningen University in September 2001 with a specialisation in wastewater treatment. From 2002–2007 she worked as a researcher on the recovery of nutrients from diluted black water. She joined Haskoning in September 2007 and developed herself into an all-around process engineer with nitrous oxide emissions and sludge treatment as her focus areas.

Frank van de Grootevheen, Process Technologist at Waterschap Vallei en Veluwe, graduated from HU with a degree in Chemical Engineering in 2015. He has been working for Vallei en Veluwe since 2015 and is involved in several projects on WWTPs, process optimizations, and reducing nitrous oxide emissions.

Sietske Riemersma, Project Manager at Waterschap Vallei en Veluwe, graduated in Medicine from Maastricht University in 1997 and trained as a pathologist at Leiden University Hospital in combination with a PhD tenure track. Having worked as a clinical pathologist for 14 years (2005-2019), she studied Environmental Sciences at the Open University and obtained her MSc. in 2021. Since the beginning of 2021 she has been working as project manager for Waterschap Vallei en Veluwe. The N2O project is one of the projects she has been working on.

Ralph Bröcheler, Process Technologist at Waterschap Limburg, graduated from HAS Green Academy in 2013 with a degree in Environmental Science. Since 1999 he has been working at Waterschap Limburg in the Netherlands, initially as an operator at various wastewater treatment plants and since 2014 as a wastewater technologist. As a wastewater technologist, he is involved in optimising the operational processes of our wastewater treatment plants.

Leon Verhaegen, Senior Project Manager ICT & Innovation at Waterschap Limburg, has been working at Waterschap Limburg for over 30 years. He specialises in digital transformation, process automation, and data-driven solutions for wastewater treatment. Leon has led major initiatives such as the WAUTER program, which centralised process control across all assets of Waterschap Limburg.

SWAN, the Smart Water Networks Forum (SWAN), is the leading global hub for the smart water sector. A UK-based non-profit, SWAN brings together leading international water utilities, solution providers, academics, investors, regulators, and other industry experts to accelerate the awareness and adoption of “smart,” data-driven solutions in water and wastewater networks worldwide. Learn more at www.swan-forum.com.