Sustainability: It's More Than A Buzzword; It's A Way Of Doing Business

For water treatment decision-makers already sensitive to issues involving water scarcity, energy consumption, and environmental stewardship, the concept of sustainability is more than just a buzzword. It is becoming a means of survival in response to changing climate impacts, high energy costs, public scrutiny, and limited financial resources. Here is how better awareness, focus, and execution can make sustainability a reality.

Sustainability — A Hot Topic, Yet Still Hard To Define

The topic of sustainability elicits a variety of perspectives. To some it means clean, renewable energy sources with reduced greenhouse gas emissions. To others it means more streamlined processes that either avoid wasting resources or actually reclaim previously used resources for a secondary purpose. From an early emphasis on environmental balance to today’s broadened perspectives on economic, social, and even business model sustainability, the definition continues to evolve.

In the water sector, sustainability is sensitivity toward more efficient use of resources and processes across a variety of factors in water and wastewater treatment facilities, industrial processes, distribution networks, and collection networks. It can be achieved in a variety of ways — e.g., with more efficient treatment processes, more cost-efficient piping infrastructure, carbon-neutral energy consumption, or zero-discharge wastewater plants (Figure 1). Whatever the perspective, knowledgeable, experienced suppliers can play an important role in helping forward-thinking organizations make their water treatment processes more sustainable and cost efficient.

Graphic courtesy of GF Piping Systems

Figure 1. Versatile and resilient, high-density polyethylene piping (HDPE) is used in many areas of industrial and municipal water and wastewater treatment applications — from chemical feed lines to filtration headers, manifolds, and more.

Sustainable Construction — A Culture Of Improvement

Sustainable construction addresses the interrelated factors of environmental, economic, and social impacts through a combination of green technology, energy efficiency, and a variety of practices designed to:

- improve the productivity or cost efficiency of design, construction, and treatment processes;

- optimize pipe sizing and layout planning to reduce energy costs and manufacturing waste/defects;

- li>improve health and safety outcomes for people in the work environment; and

- improve environmental protection.

While physical technologies and components are still important focal points, there is also renewed focus on value and on cultivating partnership and transparency among supplier, OEM, and buyer organizations for the purpose of enabling collaborative efforts and rewarding better outcomes. Sustainable construction is obviously sensitive to the environmental implications of construction materials and processes. But it also incorporates business-related interests relating to capital expense (CAPEX) and operating expense (OPEX) economic impacts on everyone from customers to employees to shareholders.

Sustainable Supply Chain Management — A Foundation For Success

Leading up to the installation phase, there are many foundational steps that can be taken to improve the potential for more favorable sustainable construction outcomes. That not only includes initial component procurement, but also related assembly, transportation, and implementation stages.

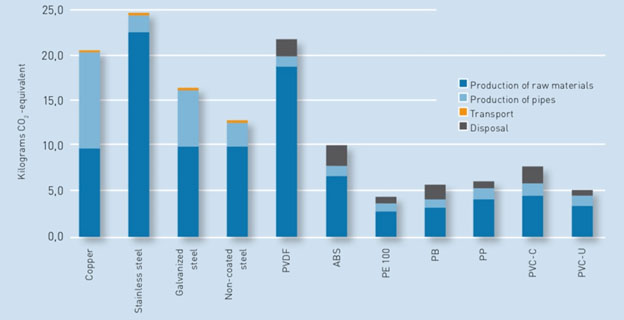

- Lower Carbon Footprints. Each component and process has an associated environmental impact. For example, comparisons show that the carbon footprint associated with many plastic piping solutions is smaller than that of other traditional metallic piping materials — with some as little as 20 percent of the carbon footprint of metallic piping materials (Figure 2).

- Recyclable Materials. Choosing materials that can be recycled at the end of their productive lifecycle reduces raw material consumption and energy costs for subsequent generations.

- Lean Manufacturing. Using prefabricated assemblies delivered to a jobsite in large segments opens avenues to both improved business efficiencies and reduced environmental impacts (Figure 3) based on reduced raw material and transportation costs.

- Reduced Energy Consumption. Prefabrication in a controlled, lean manufacturing environment powered by alternative clean energy sources helps to reduce the total carbon footprint of any application. For example, using prefabricated energy-efficient pipe designs (Figure 4) makes it easier to achieve more favorable LEED scores at data centers by minimizing unnecessary energy expenses.

- Waste Management. Specialized digital design tools maximize the yield of segments cut from bulk pipe stock. Automated production equipment provides precise control over fusing plastic piping components into complex manifolds. These steps help to minimize raw material waste and rejection rates as compared to assemblies that are cut and assembled in the field.

Graphic courtesy of GF Piping Systems

Figure 2. The carbon footprint of many plastic piping formats pales in comparison to that of traditional piping materials, across multiple factors. Their typically lighter weights also reduce the cost and carbon footprint associated with transportation.

Photos courtesy of GF Piping Systems

Figure 3. Leveraging the in-house design and manufacturing resources of a plastic piping specialist allows even complex piping systems to be assembled quickly — with minimal raw material waste, precisely fused joints, and comprehensive quality control testing. Doing so helps in streamlining final installation and promoting trouble-free performance in end-use applications.

Photo courtesy of GF Piping Systems

Figure 4. Pre-insulated plastic piping, such as the COOL-FIT piping system shown above, provides a convenient, energy-saving option for maintaining temperature stability in cooling water flows. The manufactured components simplify assembly, provide consistent thermal performance, and reduce the difficulties of insulating fully assembled conventional piping after its installation in high or inaccessible locations.

- Procurement Efficiencies. Beyond products and prefabrication assistance, online programs are also available to help companies manage their own piping component inventories more sustainably. They help to eliminate out-of-stock situations caused by human error, reduce warehouse space requirements with automated just-in-time delivery, and provide fully digitized inventory records. Such programs have been shown to reduce transport costs that represent up to 30 percent of total inventory costs, save 20 percent of time spent on administrative tasks, and increase production efficiency by 15 percent.

Shared Resources Yield Sustainable Benefits

Developing the most sustainable piping solutions does not begin and end with piping hardware alone. Here are some key resources that a plastic piping specialist such as GF Piping Systems can provide to help system design consultants, utilities, and construction contractors optimize their design and implementation efforts.

- Engineering Assistance. Taking advantage of manufacturer expertise from previous projects can help to minimize risks, speed project implementation, and make more effective use of personnel for safe, durable, and reliable piping system investments. This is especially important for applications where stressful operating conditions could impact lifetime performance. It can also help to minimize historically problematic aspects of piping installations such as pipe hangers and supports, water hammer, or product failure due to poor stress analysis.

- Online Tools. Look to helpful suppliers for guidelines that can help in choosing appropriate chemical-resistant materials, calculating flow, sizing valves and pressure-relief valves, making proper flange connections, and much more.

- Digital Libraries. Digital design resources ranging from building information modeling (BIM) libraries to plant designs to CAD libraries of tools and options can help to optimize the user experience for sustainable construction designs.

To Make A Difference, Take A Different Tack

For years, piping system designers have worked to develop systems that optimized throughput and production efficiency. Today, the goal of sustainability demands looking beyond just the physics of the process to assess total energy costs, implementation costs, and environmental ripple effects of each given application design. To keep pace, explore technical support from piping manufacturers with firsthand experience at developing new solutions to support corporate sustainability goals for current projects and future growth.