Research Team Develops Printable Water Sensors

X-ray examination shows the mode of operation of the copper-based functional compound

A Spanish-Israeli research team has developed a printable material that can be used as a versatile and robust water detector. The polymer-based fabric is inexpensive, flexible and non-toxic and changes color from violet to blue in the presence of small amounts of water. Using DESY's PETRA III X-ray source, scientists headed by Pilar Amo-Ocha from the Autonomous University of Madrid (UAM) have explored the water-induced structural changes in the material underlying the observed color change. The development opens the door to the creation of a new family of 3D printable functional materials, writes the team in the journal Advanced Functional Materials.

In many areas, such as health, food safety and environmental protection, there is a rapidly growing demand for sensors that can quickly and easily detect specific substances. Water is one of the most frequently monitored chemical compounds. "It can be very important to know how much water is present in a given environment or substance," says DESY researcher Michael Wharmby, co-author of the publication and head of the P02.1 measurement station, where the new sensor material has been studied is. "For example, if an oil contains too much water, it may not lubricate machinery well, and with too much water, fuel will not burn properly."

The functional part of the new sensor material is a so-called copper-based coordination polymer, an organic compound with a water molecule attached to a central copper atom. "Heating the compound to 60 degrees Celsius changes its color from blue to violet," says Amo-ocha. "This change can be reversed by leaving the material in the air, immersing it in water or placing it in a liquid with traces of water." With the high-energy X-ray from DESY's PETRA III research light source, the team observed that in the 60's Degree heated samples lacked the water molecules that were previously bound to the copper atoms. This leads to a reversible structural reorganization of the material, which leads to the color change.

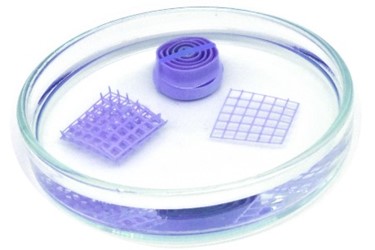

"Once we understood that, we were also able to model the physics of that change," says co-author José Ignacio Martinez of the Institute of Materials Science in Madrid (ICMM-CSIC). The researchers were then able to mix the copper compound with a 3D printer material and print sensors in various forms. They test the printed sensors in air and with liquids containing different amounts of water. It showed that the printed sensors are even more sensitive to water than the copper-based polymer material alone. The researchers attribute this to the porosity of the printed material. In liquids, the printed sensor struck within two minutes at a water content of 0.3 to 4 percent.

When the material is dried by heating or in an anhydrous liquid, it turns from blue back to violet. Tests have shown that it remains stable even over many heating cycles and that the copper-based polymers are evenly distributed throughout the printed sensors. The material remains stable in the air for at least one year, as well as at biologically relevant pH values of 5 to 7. "The versatility of modern 3D printing technology also means that these sensors can be used in very different areas," emphasizes Ko-Autor Shlomo Magdassi of the Hebrew University of Jerusalem. The concept could also be used to develop other such functional materials.

"In our work, we present the first 3D-printed composite objects from a nonporous coordination polymer," says co-author Félix Zamora of the Autonomous University of Madrid. "This opens up the opportunity to use the large family of these easy-to-manufacture compounds with their interesting magnetic, optical and electrical properties for 3D functional printing."

The Autonomous University of Madrid, the Hebrew University of Jerusalem, the Nanyang Technical University in Singapore, the Institute of Materials Science in Madrid and DESY were involved in the study.

Source: Deutsches Elektronen-Synchrotron