Putting Your Sustainability Objectives Into Practice

Organizations don’t earn Wall Street Journal recognition for being ranked ninth among the world’s most sustainably managed companies without a companywide commitment to embrace substantial operational changes. Here are examples of sustainability opportunities available in water treatment applications and how those opportunities can benefit utilities, water-consuming industries, consulting engineers, and construction contractors.

Finding Help For Achieving Sustainability Goals

A variety of criteria can be used to evaluate the compatibility of suppliers as potential partners in sustainable construction. Many of these factors can be researched in advance to confirm that a chosen supplier or contractor is aligned with the practices and processes required to support a municipal utility or industrial organization’s sustainability goals and behaviors. Key points for consideration include:

- Collaborative Partnerships. Municipal water utilities, industrial water users, their consulting engineers, OEMs, and construction firms can all advance their own sustainability goals by seeking out like-minded suppliers. In addition to direct support for specific sustainable construction projects, they can also gain new perspective from the broader sustainability experiences of their collaborators.

- Design Inspiration. Suppliers empowered with tools and expertise to advance more sustainable designs provide value in multiple ways — switching to new materials, exploring upgraded design principles, seeking higher levels of performance, or meeting increasingly demanding regulatory standards. Examples include:

- Supporting sustainable construction through innovative design with digital libraries of design tools.

- Utilizing prefabrication of plastic piping to address challenges of skilled labor shortages, compressed project timelines, and uncontrolled field installation environments.

- Promoting sustainable water management even for extremely critical applications such as high-purity microelectronics manufacturing.

- Offsite Engineering And Prefabrication Services. Taking advantage of prefabricated assembly with process automation streamlines construction in a controlled environment with access to all the resources needed to assure fast delivery of precisely fit and consistently fused joints (Figure 1). Likewise, in-house testing ensures that each shipped subassembly meets industry standards and customer design specifications. Prefabrication also helps to reduce onsite waste and streamlines the process of recycling whatever waste materials are generated.

Photo courtesy of GF Piping Systems

Figure 1. In-house access to specialized assembly resources such as plastic pipe fusing equipment makes it easier to build complex designs for advanced sustainable-process systems. Likewise, in-house testing enables 100 percent confidence in finished assemblies to minimize surprises in the final installation.

- Third-Party Standards. Suppliers who adhere to recognized disciplines and industry best practices can help sustainability-oriented customers streamline efficiency and eliminate waste.

- ISO Certification. Look for suppliers certified to major ISO standards — including ISO9001 for quality management, ISO14001 for environmental impact, and ISO45001 for occupational health and safety.

- Six Sigma Manufacturing Practices. Instilling practices to reduce defects in manufacturing processes promotes sustainability by reducing waste at the supplier’s location and reducing the risk of poor performance in the user’s application.

- Risk Reduction. Suppliers with comprehensive design, fabrication, and well-established testing protocols for their quality-control programs can help to reduce risks that often plague systems constructed under the less-than-ideal conditions experienced at field worksites.

Seek Out Suppliers Dedicated To Sustainability

For example, GF Piping Systems— a leading provider of plastic piping solutions for municipal and industrial water applications — has long embraced a multi-pronged approach to sustainability. How the company satisfies its own energy needs and reduces its own carbon footprint demonstrates the benefits it can deliver via piping materials and support services for customers concerned about their own sustainability:

- Embracing Renewable Energy Sources. Utilities and companies looking to control energy costs and reduce environmental impact have options that promote resilience and sustainability in terms of energy independence as well as environmental impact.

- Solar Energy. GF Piping Systems’ investment in more than 1,000 solar panels at its Irvine, CA, facility generates more than 500,000 kilowatt hours annually, resulting in a reduction of more than 350 metric tons of CO2 per year. That is equivalent to the CO2 sequestration provided by 440 acres of U.S. forest or by taking 78 automobiles off the road for a year.

- Fuel Cells. To achieve greater resiliency in the face of intermittent power grid outages at its Bakersfield, CA, facility, GF Piping Systems has installed fuel cells that use natural gas to generate electricity more reliably. The only byproducts are water and a small amount of carbon dioxide — no sulfur oxides and no nitrogen oxides.

For facilities such as wastewater treatment plants that produce organic waste that they might otherwise truck away, metabolizing it in an anaerobic digester and using the resulting methane to feed fuel cells that convert the gas into electrical energy can help to power production processes.

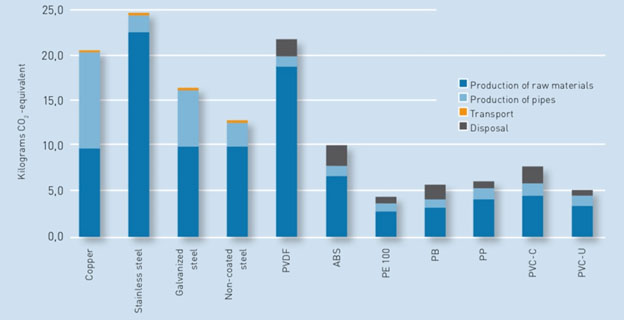

- Reducing Carbon Footprints. Using renewable energy sources is just one way of achieving a company’s sustainability goals. Using materials with a lower carbon footprint is another. GF Piping Systems offers a wide range of plastic piping materials that have been demonstrated to have as little as 20 percent of the carbon footprint compared to that of traditional metallic piping (Figure 2).

Photo courtesy of GF Piping Systems

Figure 2. Some decision-makers are surprised to learn that many plastic piping materials have a lower overall carbon footprint for production, transportation, and disposal than traditional metal piping.

- Supporting Water Reuse. Recycling spent process water as part of a zero-discharge application, or making it available for other purposes such as irrigation or cooling water, provides greater sustainability of an often-scarce resource. For example, GF Piping Systems has worked closely with the U.S.-based subsidiary of Biwater International to help the company fabricate unique manifolds for a reverse osmosis (RO) tertiary treatment system. The installation at the Albert Robles treatment plant in Pico Rivera, CA — part of the water reclamation district (WRD) serving Southern California — is shown in this video. The near-drinking-water-quality discharge from that and other WRD facilities is used to replenish freshwater aquifers and defend them against saltwater intrusion.

- Carbon Offsets. While switching to low-emission renewable energy is a great first step toward reducing a company’s carbon footprint, it is not always a total solution. Working with organizations such as Landlife — a technology-driven reforestation program — gives companies yet another way to promote sustainability. GF Piping Systems has teamed with Landlife to plant 14,000 trees in California, Oregon, and Texas — enough to offset about 60 percent of the company’s carbon footprint in the U.S. alone.

- Leading By Example. Finally, a company that backs its advocacy for sustainability with living proof of those beliefs is better positioned to understand and respond to challenges that face both municipal and industrial water treatment providers and their customers.

- Support for Water Mission — provided via both GF Piping Systems technical help and company participation in Walk For Water events — aids efforts to bring clean water to communities with infrastructure limitations impacted by climate change, natural disasters, or societal handicaps (Figure 3).

- GF Corporation’s Clean Water Foundation has invested more than $10 million over the past two decades, working with non-government organizations and local organizations to support water projects that ensure sustainability in more than 50 countries worldwide.

Photo courtesy of GF Piping Systems

Figure 3. Over the past four years, GF Piping Systems has raised nearly three-quarters of a million dollars in Walk For Water events.