Nanobubbles Boost Membrane Performance Without Added Chemicals Or Heat

Environmental engineers at the UCLA Samueli School of Engineering have developed a more sustainable way to enhance the structure and performance of ultrafiltration membranes by introducing nanobubbles during fabrication — eliminating the need for added chemicals, solvent blends or heat.

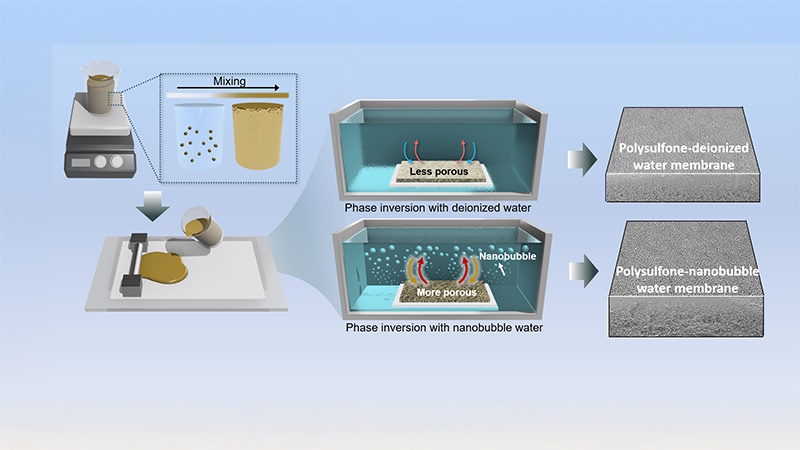

The research, published this week in Chemical Engineering Journal, shows that introducing nanobubbles into the nonsolvent bath during the phase separation process — when the membrane material changes from a liquid to a solid and forms tiny pores that filter water — can improve pore size distribution and water permeability without reducing the membrane’s ability to block contaminants.

“By introducing nanobubbles during a critical step in membrane formation, we were able to control pore development in a simple yet effective way,” said Eric Hoek, a UCLA Samueli professor of civil and environmental engineering and corresponding author of the study. “Our research findings may help simplify membrane manufacturing and improve energy and material efficiency in commercial production.”

Ultrafiltration membranes are commonly used in water treatment, bioprocessing and as support layers in reverse osmosis membranes, which push water through a semipermeable barrier to remove salts and other impurities. They are typically manufactured through nonsolvent-induced phase separation, a process in which a polymer solution is cast into a film and immersed in water or another nonsolvent. This causes the polymer to solidify and form pores, but often forces a trade-off between permeability and selectivity.

In lab-scale tests, membranes fabricated with nanobubbles showed greater porosity, thicker cross-sections and more uniform pore structures. Although the nanobubbles averaged 80 nanometers in diameter, the resulting pore sizes averaged 17 nanometers, suggesting the pore formation is governed by indirect interactions rather than a one-to-one correlation.

The UCLA team collaborated with California-based Moleaer Inc., a company that develops industrial-scale nanobubble technology used to improve water treatment and other processes across various industries.

“This project demonstrates how our nanobubble technology can enhance membrane performance while preserving selectivity, opening the door to more sustainable, efficient and scalable membrane production for next-generation filtration technologies.” said study co-author Mohamed Abdelrahman, a research and development application engineer at Moleaer.

The lead author of the study is Minhao Xiao, a UCLA Samueli civil and environmental engineering postdoctoral researcher and member of the UCLA Nanomaterials and Membrane Technologies Laboratory directed by Hoek, who also is affiliated with Lawrence Berkeley National Laboratory.

Other authors include UCLA Samueli civil and environmental engineering doctoral student Xinyi Wang and postdoctoral researcher Sungsoon Kim — both co-advised by Hoek and David Jassby, a UCLA Samueli professor of civil and environmental engineering. Other postdoctoral researchers from Hoek’s lab who have contributed to the study include Alan Quezada-Renteria and Jishan Wu, now a postdoctoral researcher at Rice University.

Source: UCLA Samueli School of Engineering