BiTurbo™: A Significant Process Improvement for SWRO

Seawater reverse osmosis systems (SWRO) are the mainstay of large-scale desalination systems. Plant designs have settled in a more or less standard configuration using a single membrane stage with permeate recoveries ranging from 38% to 45% depending on feed salinity. Yet, is this really the most optimal process design in terms of the cost of permeate?

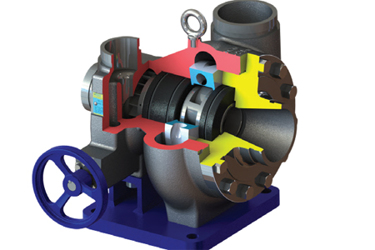

Energy recovery devices (ERDs) have settled into two types; isobaric chambers for mega scale SWRO and turbochargers for small to medium scale systems (although exceptions are easy enough to find).

This paper will argue that the isobaric chamber now most common in mega scale SWRO has inadvertently resulted in fixating on a process design that is non-optimal. An alternative process design will be described that greatly reduces capital expense (CAPEX) and operating expense (OPEX) using only well-proven components and membrane operating conditions.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.