Investigations on sludge dewatering with the separation analyser LUMiFuge 114

Utilization of flocculants for sludge conditioning allows the application of high performance dewatering machines, such as high-pressure filter presses and decanters.

Practical application studies of the sludge dewatering process and its control by flocculant addition require adequate laboratory methods. At present, numerous methods are used on laboratory scale, however, they are generally time-consuming and often lack practical relevance.

A new separation analyser has been developed

The application of a newly developed separation analyser for rapid evaluation of sludge properties and for the selection of efficient additives for sludge dewatering in decanter centrifuges is reported.

The separation analyser is based on a special centrifuge with an integrated optoelectronic sensor system, which allows one to trace the local and temporal changes of light transmission during rotation. Up to eight samples can be investigated simultaneously. A centrifugal acceleration in the range of 12 to 1200 g is used to speed up the separation process, thereby reducing the time necessary for investigation.

In preset time intervals the local transmission is determined over the entire sample length simultaneously whereby transmission profiles are generated. In the case depicted, a clear supernatant and sediment has been formed. Correspondingly, the transmission profile exhibits a section of high and a section of low transmission. The transmission profiles change during centrifugation according to the progress of separation.

The separation process can be depicted as time course of the relative position of the boundary between supernatant and sediment or of the transmission averaged over a chosen part of sample length. (For more details see www.lum-gmbh.de.)

Wastewater sludges and requirements for sludge dewatering

Wastewater sludges are very complex colloidal systems with a varying content of living and deceased biomass, exopolymers, inorganic particles and water.

The sludge flocs form loose network-like agglomerate structures as it can be seen from the microscopic image below.

Even in tenfold dilution, which corresponds to only 0.2 % total solids, it is evident that the particles occupy a large volume due to their high hydration. Comparing the two picture it can be also seen, that the sludge particles show a great tendency to self-aggregation.

The mean factors determining the ability to dewater are content and composition of organic matter, as well as structure, size distribution and charge characteristics of sludge particles. Mechanical forces due to action of a gravitational or centrifugal field or due to the pressure in a filter press lead to a compaction of the sludge network and water is squeezed out. Higher mechanical forces may lead to a breaking up of loose agglomerates accompanied by release of additional water entrapped previously. On the other hand high shear forces may cause redispersion of sludge.

The role of cationic polyelectrolytes in sludge dewatering is not only to reduce the electrostatic repulsion between the colloidal particles, but very importantly, to enhance the shear stability of sludge agglomerates. Therefore an appropriate laboratory procedure should resemble the mechanical stress before and after flocculant addition for the dewatering process used in practice as near as possible.

Case study

We had the opportunity to test our analyser on wastewater sludges which were dewatered on-site in decanter centrifuges with selected flocculants already over a longer period. We got different sludge samples (below, Table 1) and a number of flocculants, but we were not told which flocculant was appropriate in which case. So we had to try to find it out ourselves.

One of the sludges obtained resulted directly after the activated sludge process, the other two after anaerobic digestion. Despite total solids content is reduced the optimum flocculant dose increases because of the increase in organic matter content. This is due to a reduced shear stability of the primary flocs.

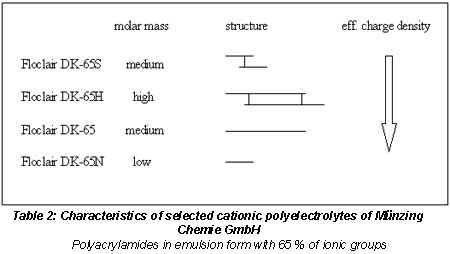

The flocculants tested on these three sludges (above, Table 2) were all of the polyacrylamide type and differed in molar mass and structure.

In addition we investigated the dewatering behaviour of anaerobic sludges (S1, S7) from another site in connection with two cationic polyelectrolytes with high molecular mass and an ionisation degree of 60%. One product was branched the other linear.

Above, Figure 3 shows the results of the characterization of the three sludges. At the left the clearing-up of the supernatant measured by the time function of average transmission, at the right the reduction in sludge volume is shown. With increasing organic content of the samples not only the limiting sludge volume increases, which detects reduced dewaterability, but also the initial sedimentation rate and the rate of the clearing-up is increased too. This might be due to the flocculating action of exopolymers, which, however exhibits no positive influence on the degree of dewatering. In addition, information about the content of fine particles—which are difficult to settle—is also available. For sludge anaerobic two, there was the highest residual turbidity, which means this sludge has the highest content of particles that are difficult to settle.

The picture shows an example for the characterization of shear sensitivity, which is an important factor, for instance in filterability of sludges. The two anaerobic sludges were sheared with an Ultra Turrax homogeniser for different times before measuring the clearing-up of the supernatant. It is obvious that the sludge with higher organic matter content shows higher shear sensitivity.

The above figure depicts the typical behaviour of sludge samples during a compression – dilatation cycle. The change in sludge volume is depicted as time course of the radial position of the phase boundary. First the samples where compacted at high centrifugal acceleration afterwards the acceleration was reduced. Due to flocculant addition a faster and higher compaction is obtained. From the picture it is evident that common centrifugation tests predict to low values for sludge dewaterability because the sediment volume increases again after switching-off the centrifuge. Due to prolonged time of shearing the elasticity of the sludge cake is reduced.

The laboratory procedure first adopted for flocculant evaluation consisted of mixing the flocculant solution and sludge in the measuring cells directly and subsequent centrifugation at 1200 x g. A second run followed after redispersion on a vortex mixer, which was intended to test the floc strength. The results obtained in relation to sedimentation rate, sediment volume, rate of clearing-up and residual turbidity all indicated that flocculant DK-65N is the most efficient additive for all of the three sludges. Unfortunately, this product fails on-site because it does not produce strong enough flocs.

To see what is wrong with the procedure we had to check the dewatering process in decanters in more detail.

In practice, the conditioned sludge is delivered into the running decanter. After passing the inlet, the sludge flocs are under a very high mechanical stress. The separated sludge is transported by the conveyer under continued centrifugal acceleration, whereby the sludge is dewatered to the residual solids content.

The laboratory procedure was therefore modified in that the sludge samples were first mixed with the flocculant solution by stirring for one minute at 750 rpm and then stressed by shearing with an Ultra Turrax homogeniser at 8000 rpm. The dewatering behaviour of the samples stirred moderately and of the samples additionally sheared were compared for different flocculants and flocculant concentrations.

In the case of sludge anaerobic I for all flocculants, the additional shearing reduces dewaterability. For higher flocculant concentrations the two curves are approaching each other. The linear products DK-65 and DK-65N exhibit a significant better performance than the branched flocculants. This is in line with the practical experience that for sludges with lower organic content branched products tend to be ineffective. The medium molecular weight DK-65 produced the best results in this case the lowest values for the sludge volume could be obtained.

Figure 7 (below) compares the results for the sludge anaerobic II. The branched polymer of medium molar mass produces stable flocs but the conditioned sludge samples exhibit bad dewaterability. Samples conditioned with the linear polyelectrolyte with low molar mass showed good dewaterability without additional shearing, however floc erosion after treatment at a high shear rate causes a substantial decline in dewaterability. The branched flocculant with high molar mass behaved similarly at lower concentrations but produced good results for concentrations near the optimum dose. The linear flocculant with medium molar mass exhibits good dewatering properties and high floc strength. For this sludge DK-65 H is used on-site, however, DK-65 was not tested there.

The laboratory procedure could not only be used for comparison of different flocculants for a special sludge to be dewatered, but also for the investigation of the influence of other parameter like sludge aging or mechanical stresses during pumping.

The final figure demonstrates the effect of mechanical conditioning on two anaerobic sludges. They were continuously pumped using a peristaltic pump in the laboratory, and at different times the sludge dewatering behaviour was investigated for different flocculant concentrations. S7 is a sludge with a lower organic matter content then S1. The total solids content of the sludge cake is depicted.

Superfloc E4208 is a linear product used on-site for dewatering of S7; SD2065 is branched. As it was observed on-site, for sludge S7 dewaterability increases with prolonged mechanical conditioning. A quite different behaviour was found for S1. For the linear product dewaterability decreased more and more with pumping, however, for the branched product dewaterability improved after going through a minimum. So, after 15 days of pumping this product got more efficient than the linear one.

There are at least two major counteracting effects, which influence the dewaterability. First, loose agglomerates are broken up, which would have not a sufficiently high mechanical stability, during flocculation more homogeneous flocs will then be formed. Second, mechanical stresses will shift the particle size distribution to lower values.

In conclusion, it could be demonstrated that:

- the separation analyser Lumifuge 114 is an efficient tool for the characterization of sludge samples and flocculant optimisation

- the development of appropriate methods for sample pre-treatment is essential for getting relevant results for sludge dewatering under practical conditions.

References

A. von Homeyer, D.-O. Krentz, W.-M. Kulicke, D. Lerche, 1999

Optimization of the polyelectrolyte dosage for dewatering sewage sludge suspensions by means of a new centrifugation analyser with an optoelectronic sensor, Colloid Polym Sci 227:637-645

T. Sobisch, D. Lerche, 2000

Untersuchungen zur Schlammentwässerung mit dem Entmischungsanalysator LUMiFuge 114 in Proceedings 14. Karlsruher Flockungstage 28./29.11. 2000 Münster, Schriftenreihe des Instituts für Siedlungswasserwirtschaft – Universität Karlsruhe (TH), Vol. 103, pp. 107 – 125.

This paper was presented at the 3rd International Conference of the Kolloidgesellschaft e.V. Adsorption and Nanostructure: From Theory to Application, Budapest, September 25–28, 2000.

About the authors: Dr. Titus Sobisch, manager research at L.U.M. GmbH Berlin/Germany Chemical engineering degree at the Technical University of Budapest in 1980. Research scientist at the Academy of Sciences in Berlin (1980 - 91, research topics: surfactants adsorption, solubilization, micellization) In the 90th surfactant formulations for soil remediation, bioreactor process development for removal of contaminants with low bioavailability. Since 1998 at L.U.M. applied research in connection with the separation analyser LUMiFuge 114. At present investigations on flocculant selection for sludge dewatering and waste water treatment.

Prof. Dr. Dietmar Lerche, founder and general manager of L.U.M. GmbH Berlin/Germany

(Back)For more information, contact L.U.M. Gesellschaft für Labor-, Umweltdiagnostik & Medizintechnik mbH Rudower Chaussee 29 (OWZ), D-12489 Berlin; http://www.lum-gmbh.de; e-mail info@lum-gmbh.de

Subscribe to our free e-mail newsletter.