Hydranautics Rolls Out New LD Technology

Hydranautics has announced its enhanced LD (Low Differential pressure) Technology, which is being used for two new spiral wound brackish water products, CPA5-LD and ESPA2-LD. LD Technology is a culmination of new advancements in biofouling and colloidal fouling reduction, and in the cleanability of these spiral elements. LD Technology consists of improved, more robust polyamide chemistry, innovative spacer geometry design to minimize the trapping of small colloidal particles, and enhanced chemical properties to minimize the proliferation of bacterial in the element. The result is longer element life, reduced chemical and labor costs associated with cleaning, and less system down-time.

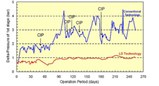

In a recent plant study, the CPA5-LD had approximately 2 bar lower differential pressure (1 bar versus ~3 bar) for most of the 250 day test, compared to conventional style elements. Additionally, the number of Clean in Place (CIP) cleanings was drastically reduced, from 5 to 0 during the 250 day test. LD Technology is enhanced with the new HYDRAblock antimicrobial technology which further reduces the ability of bacteria to populate the spiral wound element. In an additional plant trial where biofouling was a persistent problem, LD Technology resulted in considerably lower rise in differential pressure (?p). During the biofouling event, the differential pressure of the spiral elements with LD Technology had only one third of the ?p rise compared to the conventional spiral wound element.

The improved robustness of the LD Technology allows aggressive cleaning for elements treating very difficult feedwaters. The CPA5-LD and ESPA2-LD can be cleaned at wide range of pH from 1 to 13 depending upon cleaning conditions, while the robustness of LD Technology to withstand aggressive cleaning conditions ensures that membranes can be restored to their best possible performance, making them ideal for difficult to handle RO applications.

About Hydranautics

A Nitto Denko Company has state of the art manufacturing facilities at Oceanside, CA

and Shiga, Japan equipped with advanced automation to produce membrane filtration products with high

precision and of superior quality. Together, Nitto Denko Corporation and Hydranautics form the industry

leader for membrane development with a focus on unique surface coatings. The resulting membrane technology provides solutions for our customers' most demanding water treatment needs. For more

information visit www.membranes.com.

SOURCE: Hydranautics