How To Optimize Your DAF System With Air Dissolving Pumps

Dissolved air flotation (DAF) systems are a critical part of many wastewater treatment plants. They work by dissolving air into pressurized water to remove suspended solids, biochemical oxygen demand (BOD) and other contaminants from wastewater streams. DAFs are especially effective in treating wastewater with fats, oils and greases (FOG), fibers and other low-density materials, making them the preferred treatment option in industries like pulp and paper, food and beverage, and industrial laundry, among others.

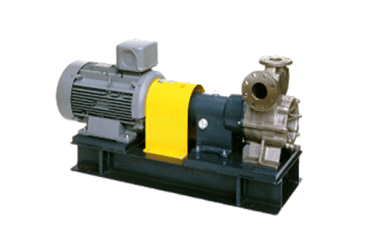

Yet despite their importance in modern wastewater applications, not all DAFs are created equal. Factors, such as the components that make up these systems, will influence how well they work and how long they last. One important DAF component to consider is the air dissolving pump. DAFs rely on the introduction of whitewater — a highly saturated and pressurized stream of air and DAF effluent — into the wastewater to create microbubbles. These microbubbles attach to the particles, lowering their density and causing them to rise to the surface. From there, the contaminants can be skimmed off and removed. With these operating principles in mind, efficient flotation depends on the quality of the dissolved air, making your choice of pump an important consideration in your DAF setup.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.