How To Do Level Monitoring Better

By Dave Walker

Existing level monitoring, usually for combined sewer overflow (CSO) or event duration monitoring (EDM) purposes has been in regular use in the U.K. for over a decade, but the equipment hasn’t changed much in that time. With the current technology comes limitations. So, the question Dave Walker, co-founder and commercial director at wastewater monitoring specialists Detectronic, has been asking is: How can we do level monitoring better for the benefit of water companies, their customers, and the environment?

EDM – Sewer Network Monitoring

External flooding in trunk sewers is a common issue faced by every water company. The sewer network has to stand up to so many challenges from natural weather events to manmade problems such as wet wipes and ‘fatbergs’. It’s inevitable that at certain times it will simply no longer be able to cope and flooding will occur. Being able to predict a problem well in advance of it occurring is, of course, the key. And to achieve that, you need consistent, robust, and highly accurate data.

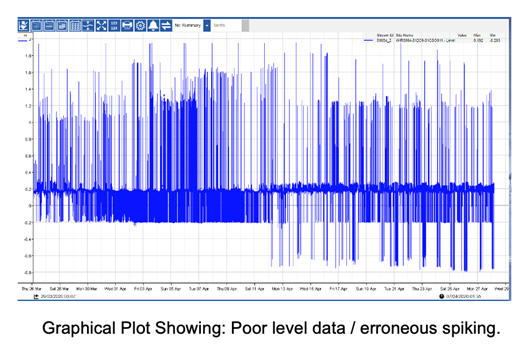

The level data below was gathered last spring from an ultrasonic monitor placed in a client’s wastewater network. The blue line along the center of the graph below is true data while the spikes are simply ‘noise’ — and therein lie the limitations of existing technology.

Figure 1.

Think about trying to have a conversation with a friend. You are one side of the road; your friend is on the other. It’s a busy road and trucks, cars, and motorbikes are driving by every few seconds. You can hear some words your friend is saying but not all of them. As the traffic speeds up and gets noisier, it’s impossible to hear anything your friend is saying, so you give up and go inside.

What would’ve made your conversation better, easier, and more productive? Crossing the road and standing next to your friend, of course. Problem solved!

True, there are companies out there that have created software with clever algorithms that analyze data and filter out noise. Surely, though, it’s better to generate reliable, accurate, and sound data from your sensor, so you don’t need fancy algorithms and additional software. More on generating decent data later!

It’s Just Too Noisy — The Limitations Of Ultrasonic Level Monitoring

The ‘noise’ spikes you can see in the data are caused by the very same proximity issue. Let’s explore the reasons for this:

- Limited range. An ultrasonic level sensor must be placed high up in the channel, normally around 3m (~10 ft.) above the invert. That’s a long way from the target being measured!

- Blanking distance or ‘dead-band’. The sensor will switch off when the wastewater in the channel gets close and, at that point, will only record a null value.

- Beam spread. Placing a sensor at 3mm equates to a 1:5 or 600mm (~24 in.) beam spread in a large asset. In a small channel, placing at 1m that could result in a beam spread of 200mm (~8 in.). The soundwaves being picked up by the ultrasonic sensor bounce off the sides of the channel within the beam spread, thus creating anomalies in the data.

- Wind speed. Any change in wind speed or the movement of air through the area being measured will affect the ultrasonic sensor soundwaves.

- Surface foaming and FOG. If the surface of the target being measured is affected by foam or there is a high density of fats, oil, and grease (FOG) in the network, they will deaden and absorb any sound that would have an effect on the data.

- Temperature. A 5°C change in temperature will result in a data error of up to 7.5mm when measuring the level within the network.

Let’s Get Closer

It’s clear from ongoing analysis (and several decades of level monitoring experience), the closer that the sensor can be placed to the target to be measured, the better. Getting up close leaves far less room for error and a cleaner, more precise echo can be achieved.

So, we set out to complete a number of trials for our existing customers, putting this concept into action and observing and then analyzing the results. We utilized a variety of different sensors, not just ultrasonic ones, including several hydrostatic pressure sensors.

Hydrostatic Pressure Sensors vs. Ultrasonic Sensors

Hydrostatic pressure sensors are very accurate when referenced to the atmosphere. They are typically mounted outside of the channel and they’re rather more reactive compared to the proactive ultrasonic sensor, since they only really start to work when something starts to happen — i.e., the sensor has to be in to contact with the liquid. When the wastewater level reaches the sensor, you know there is a problem and you must respond quickly.

Yes, we’ve outlined the limitations of ultrasonic sensors, but the fact remains that they are highly effective when implemented correctly and the limitations are mitigated; we’ve been using them in our ultrasonic level monitors for many, many years with huge success. With this in mind, and with the opportunity to carry out trials of new product development equipment across various wastewater networks, we asked the question: Why not combine the benefits of both types of sensor? Sounds simple, right? It does, but no one has ever done it, until now.

Combining The Benefits

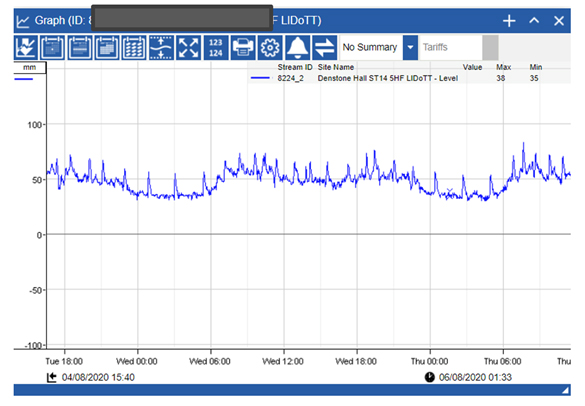

Bringing all the useful elements of ultrasonic sensors and hydrostatic pressure sensors together, our R&D team created the LIDoTT® Smart, a multi-sensor monitor incorporating both ultrasonic and pressure level technologies.

In order to get the most from the pressure sensor, the LIDoTT® Smart takes the readings from the pressure sensor and the ultrasonic sensor, then uses that data to calibrate the pressure sensor against any blockages or FOG, regardless of whether it has been offset. The result is that calibration is happening all the time, so the pressure sensor can continue working up to 10m.

Let’s compare the data between the traditional ultrasonic (see Figure 1) and the LIDoTT as outlined below in Figure 2.

Figure 2

When it comes to the ultrasonic sensor, its close proximity to the target being measured means its ultrasonic energy is focused, which delivers millimeter accuracy transmission.

Predictive Analytics

If you’re implementing smart network monitoring for proactive maintenance and pollution prevention, you need millimetric data for the predictive analytics software to give tighter predictions. The only way to get that is with good data, and to get good data out, you need to put good data in!

In combining two different types of sensor, it is now possible to gather measurements over a wider range and, by installing the sensors closer to the target of measurement (without reducing the measurement range), highly accurate results are delivered. In addition, there is no relevant dead-band; and since the pressure sensor is calibrated by the ultrasonic, the result is a device that provides reliable and accurate level sensing in any sewer scenario.

Dave Walker, co-founder and commercial director of Detectronic, began his career in the water industry as a field service technician in 1989. With qualifications initially in electronics, he later gained a BSc Hons from Sheffield Hallam University in Environmental Management, and more recently has been awarded a BA Hons in Theology from the University of Sheffield.