How Hyper-Detailed Modeling Is Strengthening Worker Safety And Water Infrastructure Resilience

By Brett Lytle

Water utilities and municipalities are under mounting pressure to modernize aging infrastructure while keeping budgets under control.

The U.S. EPA estimates utilities must invest $625 billion over the next 20 years to fix, maintain, and improve drinking water systems. When combined with EPA’s companion surveys of wastewater and stormwater systems, the total funding deficit stretches beyond $1.2 trillion over the same period.

That scale of shortfall forces owners and contractors to deliver reliable projects with leaner teams, tighter windows, and greater scrutiny.

Hyper-detailed modeling is emerging as a critical solution for these challenges, preemptively mapping every project aspect down to the individual bolt, nut, and washer. More than ever, contractors must embrace precision to reduce risk, protect workers, and give utilities a clearer path to resilient infrastructure.

Why Hyper-Detailed Modeling Is The Future

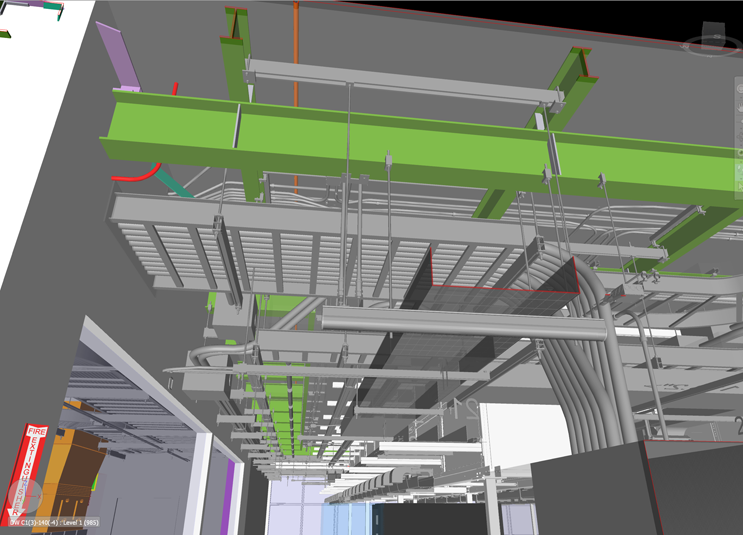

High level-of-detail (LOD) virtual models allow for clear direction and precision installations.

Most contractors today lean on some version of detailed modeling. The layouts map where the big equipment should land, how the pipes and conduits will snake through the structure, and where the most glaring clashes might crop up. Useful, yes — but limited.

Stop at that schematic level and all you really have is a sketch, or a polished outline of intent that leaves the messy realities of construction to be sorted out later in the field.

Hyper-detailed modeling refuses to leave those realities to chance. Rather than stopping at layouts or basic clash detection, it produces a virtually perfect digital replica of the facility; a model that mirrors the real build with every connection, support, and fastening detail accounted for.

That precision shifts its purpose from merely a design aid to a construction-ready rehearsal that shapes sequencing, safety planning, and job hazard analyses while showing teams exactly how, where, and when workers will move and interact with each component.

Investing time upfront in this process prevents costly surprises in the field, protecting budgets and keeping schedules on track as issues are resolved before crews arrive onsite.

In practice, hyper-detailed models depict:

- How each connection will be made in the field, from overhead racks to underground utilities

- What positions workers will be in during construction, startup, and commissioning

- Which trades will be present in the space at each phase

- Which components can be prefabricated offsite in controlled environments

- What access and clearance will look like for future operations and maintenance

- Where smaller but critical details fit in, such as instrumentation, controls, security, and lighting

With demand for industrial infrastructure climbing and skilled labor in short supply, this level of high-fidelity modeling delivers critical benefits that go beyond proactive planning and reduced onsite guesswork.

Eliminate High-Risk Entries To Improve Safety

Traditional methods often force crews into lift stations, vaults, and other confined spaces just to take measurements or confirm conditions and clearances. Each entry adds risk, even when using protective gear. With hyper-detailed modeling, many of those entries can be designed out of the process. Scans, sequencing, and digital hazard analyses capture what workers would have faced, so the plan already reflects safer pathways.

Contractors now use these models to view the:

- Body positions required for each task

- Overlap of trades in tight corridors

- Exact installation sequence to reduce congestion and risk in the field

Prefabrication adds another layer of protection. When assemblies are modeled in advance, they can be built in a controlled space instead of in extreme heat or shoulder-to-shoulder with other trades. Fewer hours spent in hazardous conditions mean less exposure to risk — sometimes as small as avoiding a cut, and sometimes as significant as ensuring someone makes it home to their family at the end of the day.

Design With Post-Build Foresight

Water projects carry a longer tail of responsibility than most other forms of infrastructure. Once the construction team demobilizes, operators step in and shoulder the burden of running and maintaining critical performance for decades. Many of the challenges they face can be traced back to design and construction choices made years earlier.

Hyper-detailed modeling makes it possible to embed operational foresight into the foundation. Equipment clearances, hoisting paths, truck access routes, and isolation strategies can all be tested long before concrete is placed or equipment is set. These details may seem small in the design phase, but they determine whether crews can swap pumps safely, access instrumentation for calibration, or fix a minor leak without triggering a full system shutdown.

When those considerations are overlooked, the impacts multiply over time. Unplanned outages, unsafe workarounds, and expensive retrofits become the rule. When they are accounted for, systems become easier to manage and safer to maintain.

Cross-Train Crews To Build Workforce Resilience

Field crews use iPads and other technology to view models and plans in real-time when accessing various parts of the jobsite.

In 2025, the industry must attract 439,000 additional workers just to meet demand, according to Associated Builders and Contractors. For water and wastewater projects, where specialized skills are vital, that gap hits especially hard.

Against that backdrop, hyper-detailed modeling has become as much a tool for workforce development as it is for project planning. During slower cycles, contractors can shift field crews into the modeling and prefabrication process.

Instead of dropping from a 40- to 60-hour week to 20, workers stay busy and keep a sense of normalcy in their schedule. This training builds digital fluency while reinforcing practical knowledge, creating another way to be a tradesman in the industry.

Likewise, when demand surges, prefabrication crews can move into the field to keep delivery steady and workloads balanced, shifting between shop, field, and digital roles without breaking stride.

Use Technology To Enable Precision

Topographical heat maps allow for crews to see the volume of material to be moved in initial site prep.

Unknown conditions are a constant in water infrastructure. Utilities buried decades ago may not appear on current records, and undocumented structures often surface during excavation. These surprises derail schedules, force redesigns, and extend outages.

Hyper-detailed modeling grows even more powerful when paired with modern reality-capture technologies such as:

- Drone surveys that deliver high-resolution surface mapping to capture treatment plants, pump stations, and corridors quickly and safely without repeated manned entries.

- Ground-penetrating radar to identify subsurface utilities and structures that drawings missed, reducing the chance of striking buried obstructions.

When layered into a federated model, these datasets create a full picture of existing conditions. Crews can plan excavation with confidence, prefabricate spools and assemblies to exact dimensions, and sequence work with fewer interruptions.

For water and wastewater projects with narrow margins and unforgiving shutdown windows, this degree of precision supports seamless execution and avoids the costly ripple effects of rework.

Tomorrow's Water Infrastructure Lies In The Details

In a sector where every delay compounds, modeling with such granular detail is no longer optional. It is fast becoming the new foundation for more resilient, sustainable, and trusted water infrastructure.

Brett Lytle is senior vice president at self-perform water and wastewater general contractor RMCI, an operating company of large-scale industrial construction enterprise Nox Group.

Brett Lytle is senior vice president at self-perform water and wastewater general contractor RMCI, an operating company of large-scale industrial construction enterprise Nox Group.