Harnessing The Power Of Oxidation-Reduction Potential For Smarter Wastewater Management

By Emma Flanagan

“Potential” is in the name. Here’s what wastewater managers should know about both the benefits and challenges of ORP as an agent of process control.

In today’s rapidly evolving water resource management landscape, wastewater treatment facilities are under unprecedented pressure to improve operational efficiency, reduce chemical consumption, and meet tightening environmental regulations. One powerful, yet underutilized, tool in this effort is oxidation-reduction potential (ORP) — a real-time, integrative metric that enables more intelligent control of redoxbased chemical and biological processes.

A Real-Time Indicator Of Chemical And Biological States

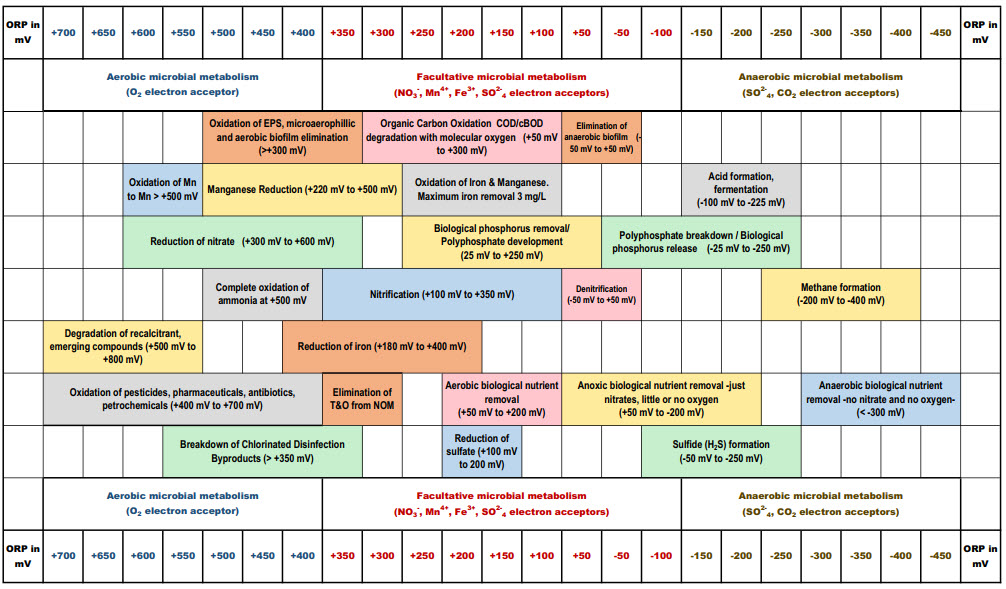

ORP, measured in millivolts (mV), reflects the balance between oxidizing and reducing substances in a water system. High ORP values typically indicate an oxidative environment conducive to aerobic processes, disinfection, and the breakdown of organic matter. Conversely, low or negative ORP values correspond to reducing conditions, which support processes like denitrification, sulfate reduction, and methanogenesis.

ORP provides operators with an instantaneous snapshot of the system’s redox state, allowing for real-time process adjustments without relying solely on laboratory analysis. This makes it an invaluable tool for optimizing treatment efficiency, microbial health, and system stability.

Expanding Applications Of ORP In Wastewater Treatment

Initially used primarily in industrial settings, ORP is now widely adopted in municipal wastewater treatment plants. Its applications span across all major biological treatment stages: carbon removal, nitrification, denitrification, anaerobic digestion, and biological phosphorus removal.

In aerobic systems such as activated sludge basins and trickling filters, maintaining ORP values between +300 and +400 mV supports the activity of aerobic bacteria, which are responsible for the oxidation of organic matter and ammonium. During nitrification, keeping ORP above +50 mV helps prevent nitrite accumulation and ensures complete conversion to nitrate.

In anoxic zones, facultative bacteria such as Escherichia coli switch to using nitrate as an electron acceptor when oxygen is absent. Here, ORP values typically range from +100 to -50 mV. Operators can use real-time ORP data to detect the completion of denitrification, which allows for more efficient nitrate removal and energy savings by preventing unnecessary aeration.

Anaerobic digesters, which host methanogenic archaea, require strictly reducing environments. ORP values below -300 mV — ideally around -330 mV — are necessary for optimal methane production and volatile solids reduction. Managing ORP in these systems enhances gas yields and reduces issues related to odor and sludge instability.

Biological phosphorus removal involves alternating anaerobic and aerobic conditions. In the anaerobic phase, phosphorusaccumulating organisms (PAOs) release phosphorus and uptake volatile fatty acids, a process best maintained at ORP values below 0 mV. In the subsequent aerobic phase, ORP between +25 and +250 mV supports the uptake of phosphorus into biomass.

ORP is also a critical tool in odor and corrosion control. Maintaining ORP above -50 mV in sewer lines and holding tanks helps prevent the formation of hydrogen sulfide (H₂S), a major contributor to odor issues and infrastructure corrosion.

Performance Benchmarks And Case Evidence

The effectiveness of ORP-based process control is well-supported by empirical studies and case applications.

A U.S. municipal wastewater plant implemented ORP monitoring in its anaerobic digesters and achieved a 15% increase in methane production, along with a 40% decrease in hydrogen sulfide emissions. Another facility, managing an aerobic activated sludge system, used ORP to modulate aeration dynamically. This resulted in a 25% reduction in energy use while maintaining effluent quality within permit limits.

In Germany, a municipal facility employing enhanced biological phosphorus removal integrated ORP into its control strategy. The optimized transition between anaerobic and aerobic phases led to a 20% improvement in phosphorus-removal efficiency and significantly reduced chemical-phosphate binders.

Integrating ORP For Process Control

Real-time ORP monitoring provides an affordable and actionable indicator of biological activity. Unlike isolated parameters such as pH or dissolved oxygen (DO), ORP integrates the cumulative impact of multiple factors — including oxygen levels, temperature, and microbial metabolism — into a single, holistic measurement. This makes it especially valuable in treatment systems where chemical and biological interactions are complex and dynamic.

Operators can use ORP to fine-tune aeration intensity, adjust chemical dosing, and detect process upsets sooner. In many cases, ORP data allow for a shift from fixed setpoints to dynamic, demandbased control strategies. For example, rather than maintaining a fixed DO concentration, plants can modulate aeration based on ORP to meet microbial oxygen demand while minimizing energy waste.

Practical Considerations And Limitations

Although ORP is a powerful process control metric, it is not without challenges. Readings are influenced by various factors such as pH, salinity, and the presence of multiple redox-active species. As such, ORP values must be interpreted in the context of the specific treatment stage and system configuration.

Successful implementation requires regular probe calibration, system-specific setpoints, and integration with other sensors and supervisory control systems. When deployed thoughtfully, however, ORP becomes an indispensable component of intelligent, automated wastewater operations.

The Future Of ORP In Smart Water Management

As utilities increasingly adopt automation and digital transformation, ORP is becoming a foundational element of data-driven water treatment. Its compatibility with modern SCADA systems and its ability to serve as a proxy for multiple process indicators make it well-suited to support real-time decision-making and predictive control.

In an era where sustainability and efficiency are no longer optional, ORP offers a compelling return on investment. By enhancing microbial process control, reducing chemical and energy consumption, and preventing odor and corrosion, it positions wastewater treatment plants to operate more effectively and responsibly.

Conclusion

Oxidation-reduction potential is far more than a laboratory curiosity; it is a practical, real-time metric that connects microbial activity, chemical reactivity, and system performance. With proper calibration and system integration, ORP monitoring empowers operators to make faster, smarter decisions across all stages of wastewater treatment.

By shifting from reactive to proactive control, plants can not only meet regulatory targets but also lower operational costs and environmental impacts. In the pursuit of smarter, cleaner, and more sustainable wastewater management, ORP is a tool whose time has come.

About The Author

Emma Flanagan is the CEO/CTO of Envirocleen, LLC, an Illinois water treatment consulting company, manufacturer, and distributor of mineral oxychloride advanced oxidation reagent and quantum disinfection technologies. Email: info@envirocleen.com.

Emma Flanagan is the CEO/CTO of Envirocleen, LLC, an Illinois water treatment consulting company, manufacturer, and distributor of mineral oxychloride advanced oxidation reagent and quantum disinfection technologies. Email: info@envirocleen.com.