Grit's True Impact On Wastewater Treatment Quality And Costs

Grit buildup that is ignored or improperly addressed can have profound effects on both treatment efficiency and maintenance costs, even if it does not impact effluent quality. Here are some of the cost implications and physical effects of inefficient grit removal, along with some important considerations on the impacts of letting grit go unmanaged.

The History Of Grit Handling

Part of the problem with inefficiency traces back to the early history of grit-removal efforts, when the conventional standard defined grit as spherical silica sand with a minimum diameter of 212 microns and a specific gravity of 2.65. But that arbitrary standard was established at a time when biological treatment was nowhere near as crucial as it is now. Today’s experiences show that using a 1942 standard allows a variety of problems to impact modern wastewater treatment plant (WWTP) operations.

Understanding Grit’s Real Impact

For WWTP superintendents and consulting engineers faced with decisions on what grit removal actions to take, it is first important to appreciate grit’s influences and impacts. Whether designing grit removal systems for new plants, upgrading existing options due to process changes, or retrofitting them into smaller plants for the first time, the available footprint and hydraulic profile have big impacts on grit handling decisions. Here are some key considerations about how the physics of grit particles can impact those choices:

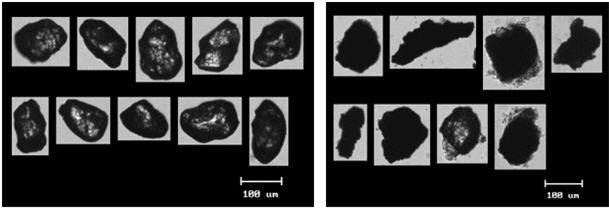

- Grit Composition. Not all grit is created equal. Because grit can come from a variety of sources, each with its own physical characteristics, it is important to consider how settling velocity — not just size or specific gravity — will have the greatest impact on its behavior within a WWTP (Figure 1).

- Mineral Elements. Even if the majority of grit has the same specific gravity, irregularities in the size and shape of the particles impact how quickly or slowly each particle will settle out of the flow in a grit removal system.

- Biological Elements. Aside from sand, there can be a variety of other grit components — seeds, egg shells, coffee grounds, etc. — each with its own specific gravity, range of sizes, and shape irregularities.

Photos courtesy of Hydro International

Figure 1. Not all grit particles of the same size settle at the same rate. Comparing the shape and surface irregularities of sand (left) vs. other materials (right) makes it easy to appreciate how different grit makeup can create significantly different settling velocities and impact grit removal rates.

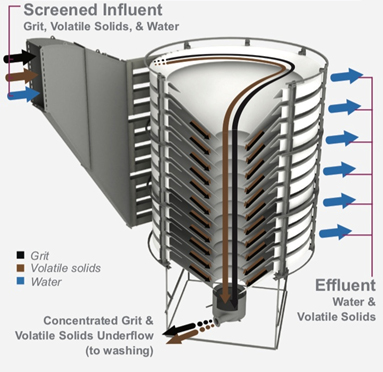

Graphic courtesy of Hydro International

Figure 2. Modern grit separation designs based on the actual settling velocity of grit in a wastewater flow can now remove up to 95 percent of particles measuring > 75 micron.

- Grit Removal Sizing. Grit behavior changes according to material and size. Systems designed to remove particles of 212 microns or larger can still allow as much as 50 percent to 70 percent of grit mass to enter the treatment train (Figure 2).

Classifying grit particle characteristics by overall settling velocity (or their sand-equivalent size) is the best way to understand the behavior of the grit in order to capture the majority of those particles. Both the Water Environment Foundation (WEF) Manual of Practice #8 and the Metcalf & Eddy manual on Wastewater Engineering: Treatment And Resource Recovery now address the recovery of finer particle sizes. This WEF fact sheet includes the concept of sampling grit composition based upon actual wastewater flow over time to aid in more informed design decisions. Without a universal test methodology for grit analysis, it is important that WWTP superintendents, operators, and design engineers reference state or regional analyses of grit composition or have a custom analysis done by an independent wastewater specialist.

- WWTP Configurations. The importance of grit removal is also related to WWTP construction and how wastewater flows through it. For example, low-energy anoxic basins used for biological nutrient removal (BNR) processes typically do not have enough turbulence to keep grit suspended. Also, grit settling out to the bottom of aeration basins can obstruct nozzles, reduce oxygen circulation, compromise biological treatment efficiency, and drive up the overall cost of achieving effluent regulatory requirements.

- Deposition. Grit deposits can also lead to inconvenient, messy, and costly cleanout events — often ranging between $100K and $200K per digester cleaning. And beyond those costs is the risk of damage to aeration infrastructure by workers shoveling grit out of the bottom of basins.

- Abrasion. Grit manifests itself in wear on WWTP equipment — pumps, piping, nozzles, and other mechanical components — that is hard to detect during continuous operations. Much of what is attributed to normal ‘wear and tear’ during periodic maintenance inspections can actually be due to high volumes of grit in wastewater running through the plant.

Graphic courtesy of Hydro International

Figure 3. A cost of grit calculator can help WWTP decision-makers gauge savings on grit cleanouts, pump wear and maintenance, and other repairs based on the specifics of their own operations.

So What’s The Answer?

Similar to the adage that “those who ignore history are doomed to repeat it,” it can be said that those who fail to manage grit at their headworks will be managing it throughout the rest of their plant. This guide to the hidden costs of grit enables decision-makers to appreciate and calculate the negative impacts of inefficient grit removal. Here are several key points to take into account before making new grit removal decisions:

- Calculating Grit’s Impact. This cost of grit calculator helps decision-makers compare the current impacts of uncaptured grit or older, less efficient grit removal processes vs. more modern approaches using job-matched solutions for particular applications (Figure 3).

- Grit Separation Efficiency. Today’s technologies have advanced far beyond the old standard of removing 90 percent of grit sized > 212 microns, to the point of achieving 95 percent removal of grit > 75 microns.

- Retrofit vs. New Construction. Different technologies available in freestanding and in-situ designs offer affordable solutions for a wide range of applications — including retrofit applications as small as 0.25 MGD.

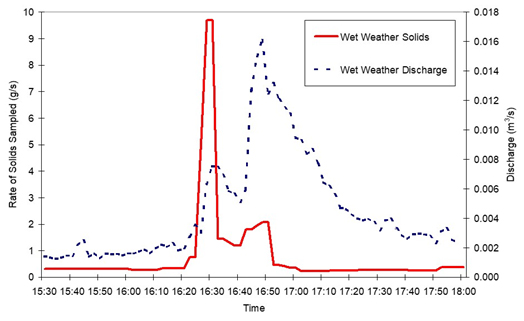

- Matching Size Requirements Cost Effectively. How a WWTP establishes grit removal targets can vary based on the nature of the grit and historical peak flow rates. For example, achieving 106-micron removal at peak flows will typically equate to 75-micron removal at average flows. Those targets can be adjusted if peak flows are extremely high or if grit size distribution skews particularly fine as in areas with large volumes of ‘sugar sand.’ In any case, it is advisable to aim for grit removal effective enough to accommodate the peak of first-flush concentrations (Figure 4).

Graphic courtesy of Hydro International

Figure 4. The dramatic difference between normal and peak rates of solids/grit inflow — particularly around ‘first-flush’ events — demonstrates the importance of properly matched grit removal equipment.

Marcia Sherony is Sales Director for Hydro International’s Water and Wastewater Division which specializes in the development, design and fabrication of high performance equipment and systems for removal of grit and primary solids. Mrs. Sherony has worked with market leaders in liquid/solid separation for over 30 years. She has experience in both the municipal and industrial markets providing equipment solutions.

Marcia Sherony is Sales Director for Hydro International’s Water and Wastewater Division which specializes in the development, design and fabrication of high performance equipment and systems for removal of grit and primary solids. Mrs. Sherony has worked with market leaders in liquid/solid separation for over 30 years. She has experience in both the municipal and industrial markets providing equipment solutions.