Future Assured As Second And Third Generations Take Gravel Ridge Forward

The move away from lagoons to becoming a fully mechanical treatment plant has certainly rung the changes at a small facility just north of Little Rock, Arkansas. The WWTP’s history and managing of the steep learning curve has been a true family affair.

For over five decades, sewage was treated at Gravel Ridge by partially-aerated lagoons, which met all required discharge limits. The man firmly behind the makings of this inaugural process for the town was the late Clarence Phillips.

Today it is his grandson, Jacob Phillips (37) who is at the helm as Site Superintendent, though only a couple of short years ago, he was busy maintaining housing for the US Air Force. His move to The Gravel Ridge Sewer Improvement District 213 is firmly down to his father, Mark Phillips (63), who has worked at the facility for the past 35 years. If there isn’t a plan to mount a special Phillips family plaque at the WWTP or in the town, there should be!

“Dad knows where absolutely everything is here,” says Jacob. “Everything! But as soon as it became known that a mechanical plant was on the horizon, he asked me to change my job and come in to help run it! Let’s just say that he’s not exactly a big fan of computers!”

As populations rapidly increase and discharge limits only become more stringent of course, the upgrade at Gravel Ridge to a full mechanical treatment plant was inevitable, with the renowned wastewater treatment specialists Halff appointed to design the new plant.

Halff’s Vice President, Mike Marlar, commented: “New discharge limits made by Arkansas’ State Department of Environmental Quality meant that the lagoons at Gravel Ridge couldn’t meet the required BOD of 10mg per litre and TSS of 15mg per litre. There was also a new ammonia/nitrogen limit to adhere to. We soon saw that although we were introducing a whole range of new equipment, there would also be a big benefit in repurposing the old assets by keeping the lagoons to help the plant for the long-term future.”

Located in North Pulaski County, Gravel Ridge Sewer Improvement District 213 (which serves 2000 customers) is not under the ownership of an incorporated city. Instead, it has its own stakeholders and facility owners, who in addition to recognizing the need for a new wastewater treatment plant,commissioned an infiltration inflow study on the collection system to see how the impact of heavy rainfall could be lessened at the treatment works.

Mike Marlar from Halff added: “The site had an area of approximately two acres that was large enough to house the new, 700,000 gallons per day mechanical treatment plant. We set about designing a system with a new pump station so that sewage could be pumped into the treatment process, and when required, diverted into the lagoons during wet weather flows, before being allowed to slowly drain back. Having the lagoons there for equalization is very useful.”

He continued: “Just a few years earlier, Gravel Ridge had removed large layers of built-up sludge in the lagoons, so this really helped facilitate their use for the new-look application. As well as storm overflow, the lagoons can also store sludge, which reduces costs for Gravel Ridge on sludge treatment and sludge dewatering.”

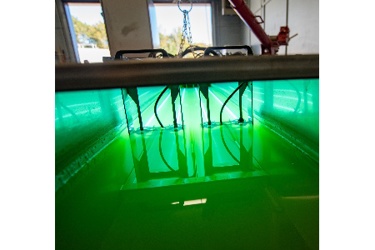

In addition to the influent pump station, the new 700,000 gallons a day treatment plant includes a head work facility that includes mechanical screening and grit removal. In the main part of the treatment process there is an extended aeration-activated sludge process. This is the racetrack, with a circular basin with both the aeration and clarification process. The clarifier is in the very center of the circle, and then on the outside track, outside of the clarifier, the track for mixing and aeration, incorporating the activated sludge process. This is where BOD is removed and nitrification occurs, and cobalt-suspended solids are treated and then settled out in the center clarifier before the treated wastewater flows over to the tertiary (disk) filtration system. Following the eight disk filters, coliform and fecal coliform bacteria are removed with ultraviolet light (UV) disinfection before the flow enters a post-aeration basin and on to a partial flume. The treated wastewater is then discharged into the Bayou Meto, a tributary of the Arkansas River. Almost all of that new investment comes in the shape of wastewater treatment systems from Lakeside Equipment Corporation, supplied through their long-standing representative in Arkansas, Instrument & Supply (established in 1980).

‘Very durable over the long term’

Halff’s Mike Marlar explained: “I had no hesitation in recommending Lakeside for this project because I’ve had such good success with them throughout the years. This goes all the way back to 1995 at Camp Robinson, which is still in perfectly good working condition, meeting all state compliance requirements, so they're very durable over the long term. More recently at Bull Shoals, Lakeside helped the plant win the coveted Arkansas Engineering Excellence Award – Water and Wastewater; American Council of Engineering Companies (ACEC).”

‘The flexibility of how you can increase and decrease the oxygen level in the aeration basin

He added: “So at Gravel Ridge from the headworks onwards (apart from the disk filters and UV) it is pretty much all Lakeside, including a cylindrical mechanical screen, all of the aeration equipment, with two covered rotors and the circular clarifier. I really like the flexibility of how you can increase and decrease the oxygen level in the aeration basin by simply raising or lowering the effluent weir to allow water to flow from the aeration basin into the clarifier. By increasing the height of the weir, you increase the submergence of the rotors and thereby increase the oxygen level in the wastewater in the aeration process. And if the operator lowers the effluent weir that transfers water to the clarifier, the oxygen concentration is reduced in the aeration basin. It is very flexible.”

‘Create some good, happy biology’

Jacob Phillips added: “Heavy rainfall keeps us on our toes. We’re a small team; just me, Dad, and Ivan Thunderman, but we’ve been learning fast, taking our time to create some good, happy biology, getting everything balanced so that our mixed

liquor is where it is supposed to be. Everything is running just fine. We get really good clarity and water consistency. Really clear water.

“All the Lakeside gear is very easy to work on. It took us a little bit of adjustment because we went from that traditional lagoon system with no moving parts at all, but once we got everything fine-tuned and figured out, the system is really good on that side and largely runs itself. And if I want to know where anything is, even the most obscure manhole, my Dad will know exactly where it is and the whole history behind it!

“Like any treatment plant, we have to be aware of any extra infiltration, but when the lift station in front of our treatment plant approaches high water levels, it does kick it out into those lagoons, which is very effective. It’s all been quite a big transformation, but we have a very well-designed plant from Halff, and excellent equipment from Lakeside.”

Source: Lakeside