Desalinization Less Costly, More Effective

One of the technologies in the world of water treatment that has progressed significantly during the last decade, both in affordability and efficiency, is desalinization or desalting of water.

Ionics, Incorporated, an international company that specializes in the treatment of water, has released several case studies of late that illustrate instances where desalinization is working.

Sarasota sought an additional water source

The rapidly growing County of Sarasota on the West Coast of Florida needed an additional source of potable water. A 24,000-acre wellfield and ecological reserve with eleven 400-foot wells was a possible feedwater source. However, these wells had water with variable salinity, over 2 ppm hydrogen sulfide, and were saturated with calcium sulfate and calcium fluoride. In demineralizing these brackish well waters, the wastewater volume—which would be sent to injection wells for disposal—needed to be minimized.

Within its own borders, Sarasota County has Ionics Electrodialysis Reversal facility, the largest municipal water treatment facility of its type in the world, according to Ionics. That facility was selected to demineralize the brackish well water to drinking water standards.

Although pilot studies also evaluated ion exchange and reverse osmosis process, Ionics EDR was chosen because of its ability to maximize recovery of fresh water and minimize wastewater volume.

Plant operates at 85% water recovery

The robust lonics EDR plant has produced more than five-billion gallons of drinking water during its first three years of operation, and the plant operates at 85% water recovery, limited by the supersaturated calcium sulfate concentrations (over 250% or 6.25 x Ksp) in the brine stream.

This impressive 12 MGD installation, controlled by a central SCADA instrumentation system, consists of ten individual EDR systems, each controlled by a PLC.

Cape May's supply threatened by salt water

In the Northeast, the City of Cape May, NJ, presented another challenge. It is a National Historic site and a favorite vacation spot for beachcombers, bird watchers and artists. Tourism is a major industry in the picturesque community on the southernmost tip of New Jersey.

Unfortunately, however, as a result of salt water intrusion, the same ocean that has brought so much prosperity for the city, has also threatened to compromise its water supply. The city had already abandoned three of its supply wells due to high salinity. Water supply during the peak tourist season was limited and the city feared losing a fourth well.

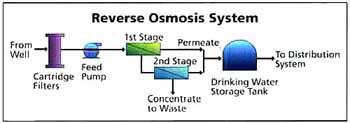

Ionics' brackish water reverse osmosis was selected as the most economical method of supplementing the city's present fresh water supply by Metcalf and Eddy, engineering consultants to the City of Cape May.

A one million-gallon per day (mgd) system was delivered to the city in May 1998 and a 1 mgd expansion was ordered in June. The 2 mgd system is the first major use of membrane desalting by a municipality in the northeast. Ionics' skid-mounted design and integrated SCADA control package minimized installation costs and provided for a cost-effective expansion of the system during the preliminary construction phase.

By baseloading the operation of the membrane desalting plant, the city hopes to prevent further salt-water intrusion into the remaining fresh water wells.

New facility built on Island of Caracao

At another tourist spot, this time in the Caribbean, Ionics' seawater reverse is augmenting an existing seawater desalination facility on the island of Curacao, the largest of the five islands of the Netherlands Antilles.

Faced with increasing demand for potable water and an aging distillation plant for evaporating seawater, Kompania di Awa i Elektrisidat Di Korsou (K.A.E.), the local water supplier, wanted to increase its existing capacity to meet drinking water demand as well as expand its range of technology capabilities for producing potable water via seawater desalination.

Ionics provided a membrane-based solution, an ultra-high-efficiency energy recovery process, to augment their existing desalination facility. Ionics Aqua Design designed, built, owns and operates a 3,000 cubic meter per day (800,000 gpd) reverse osmosis desalination facility adjacent to K.A.E.'s existing desalination plant, to produce fresh water from seawater. Ionics' staff of "desal" specialists supervise the operation and maintenance of the plant as well as provide the customer training on operating the new RO system, in addition to pre-existing evaporators.

The product water produced by the Ionics SWRO system matches the quality of the thermal desalination units at less than 20 ppm TDS.

Edited by Joyce Jungclaus, Editor, Public Works Online, of the VerticalNet family of online business-to-business e-commerce communities.

Information provided by Ionics