Redesigning Brine Diffusers: Optimizing Brine Dispersion Performance At The Hadera Desalination Plant

By Dotan Gur

As global water scarcity intensifies, desalination has become a critical solution for ensuring reliable freshwater supplies. However, the environmental impact of brine, the concentrated saline byproduct of desalination, remains a key challenge for plant designers. The Hadera Desalination Plant in Israel, operated by H2ID Ltd (a partnership with IDE Technologies), recently faced a major challenge with their brine outfall discharge. This article explores how IDE Technologies leveraged advanced in-house simulation capabilities to deliver a revised brine diffuser design, significantly improving both environmental outcomes and operational efficiency.

The Hadera Desalination Plant: Background And New Challenges

Since its commissioning in 2009, the Hadera Desalination Plant has supplied 137 million cubic meters of drinking water annually, making it a linchpin in Israel’s water infrastructure. Located adjacent to the Orot Rabin power station near Hadera, the desalination plant historically relied on blending its brine with the power station’s cooling water before discharging the mixture into the Mediterranean Sea.

A major shift began when Orot Rabin initiated the conversion of four power generation units from coal to natural gas. This transition meant the closure of the cooling water channels, forcing the desalination plant to implement an independent solution for brine disposal. The State of Israel and H2ID Ltd signed an agreement in 2020 to construct a dedicated offshore tunnel and brine diffuser system. This new approach would maintain compliance with evolving environmental regulations and ensure the plant’s operational sustainability.

Engineering A New Solution: From Gravity-Fed To High-Performance Diffusion

The new brine disposal system required a sophisticated design to replace the former gravity-fed method. The Water Desalination Administration of Israel (WDA) and H2ID Ltd enlisted an international engineering firm to develop a solution that would:

- Transport brine through a 2-kilometer offshore tunnel to a marine diffuser.

- Limit overall head-loss to 3.5 meters to prevent flooding and maintain operational safety.

- Achieve effective brine mixing at both normal (23,000 m³/hr) and peak (41,000 m³/hr) flow rates, with a constraint of low exit velocity from the brine diffusers ports.

The new design addressed these challenges and received approval from Israeli authorities. However, as the project entered execution, the suggested design faced major gaps and disadvantages risking contract performance guarantees.

This crisis prompted IDE Technologies to undertake a comprehensive redesign in late 2022.

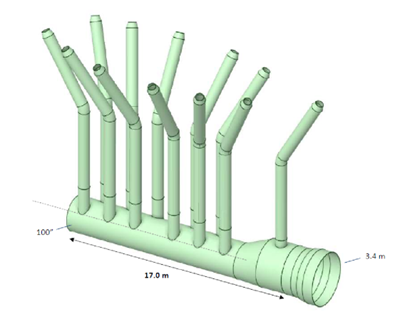

Figure 1. Original diffuser design

Bringing Simulation In-House: The Strategic Advantage

Traditionally, advanced brine dispersion modeling is outsourced to specialized consultants, a process that can introduce misalignment and costly delays if late-stage changes are required. Recognizing these risks, IDE Technologies invested in building robust in-house computational fluid dynamics (CFD) capabilities, this activity is being led by Dr Eyal Price, Head of the Hydraulic Engineering Team. This strategic move enabled the company to:

- Integrate simulation results directly into the design process from the earliest stages.

- Rapidly iterate and optimize diffuser designs.

- Ensure compliance with stringent local and international environmental standards.

The revised diffuser design for the Hadera plant is a testament to the value of this approach, enabling IDE to deliver a solution that meets and exceeds regulatory and operational requirements.

Computational Fluid Dynamics (CFD): A Game-Changer For Brine Diffuser Design

CFD is a powerful tool for predicting fluid flow, heat and mass transfer, and chemical reactions in complex systems. Using ANSYS-FLUENT 2023R2, IDE’s engineers created detailed 3D models of the brine diffuser and the surrounding sea environment. This allowed them to:

- Visualize the dispersion of brine in all directions and at varying depths.

- Assess the impact of variables such as brine density, temperature, sea currents, and nozzle flow rates.

- Optimize nozzle configuration to prevent jet merging and maximize dilution.

CFD modeling is increasingly recognized as best practice in the desalination industry, with successful applications documented in Australia (Gold Coast, Sydney, Melbourne, Adelaide, and Perth plants) and supported by academic research. Compared to traditional empirical models, CFD provides a more nuanced understanding of multi-plume interactions and site-specific dynamics, leading to more reliable and environmentally sound designs.

The Revised Diffuser: Design Features And Performance

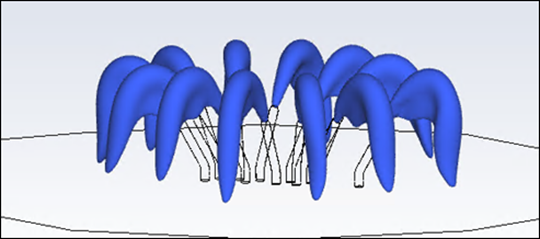

Figure 2. Revised diffuser design

Figure 3. CFD brine plums – revised diffuser design

Key design improvements:

- Nozzle orientation: The revised design eliminates the risk of jet merging by ensuring that nozzles are not directed at one another, a recommendation validated by near-field modeling using the US EPA’s Visual Plumes software.

- Shortened structure: The diffuser’s length was reduced from 60 meters to 18 meters, significantly decreasing the marine construction footprint.

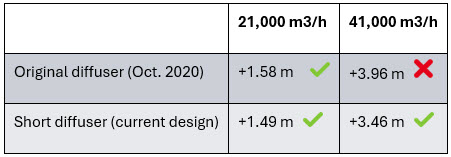

- Hydraulic optimization: CFD analysis confirmed that the new design meets the maximum allowable water level in the brine pit (+3.50 m MSL), even at peak flow, thus preventing flooding risks of onshore infrastructure unlike the original design.

Calculated water levels in the brine pit (MSL)

Environmental performance:

- Reduced salinity impact: The revised diffuser achieves an excess salinity of just 7.1% at the seabed impact point, compared to 9.8% in the original design. This improvement ensures compliance with the Ministry of Environmental Protection (MOEP) criteria and minimizes ecological risk.

- Lower construction impact: The shorter diffuser reduces excavation and backfill requirements by approximately 20,000 m³, halving the environmental disturbance to the seabed and shortening the construction timeline.

Operational and contractual benefits:

- Schedule risk reduction: Less marine work means fewer weather-related delays and greater availability of construction equipment.

- Regulatory compliance: The design fully meets contractual requirements for maximum water level and environmental performance.

Lessons From Hadera: The Broader Value Of Early-Stage Simulation

The Hadera case highlights the critical importance of conducting brine dispersion simulations early in the project lifecycle. By integrating modeling at the outset, project teams can identify and mitigate potential design and regulatory risks before they escalate, ensuring that the final design meets both operational and environmental requirements. Early-stage simulation also leads to more accurate budgeting and scheduling, enabling engineers to foresee challenges and allocate resources more effectively. Furthermore, this proactive approach helps avoid costly late-stage redesigns or operational failures that might otherwise arise if issues are discovered during construction or after commissioning.

In essence, early brine dispersion modeling serves as a foundational step for the successful, efficient, and sustainable development of desalination projects.

Conclusion: Setting A New Standard For Sustainable Desalination

The revised brine diffuser at the Hadera Desalination Plant demonstrates how integrating advanced CFD modeling and in-house simulation capabilities into the design process can deliver tangible environmental and operational benefits. By proactively addressing regulatory, technical, and ecological challenges, IDE Technologies has set a new benchmark for sustainable desalination infrastructure.

As desalination projects proliferate worldwide, the lessons from Hadera underscore the necessity of early, integrated design approaches. Investing in simulation capabilities not only streamlines project delivery but also ensures that desalination remains a viable and environmentally responsible solution for water-scarce regions.

Dotan Gur holds a B.Sc. in Agricultural Soil and Water Sciences from Hebrew University. With over 18 years at IDE Technologies, he leads global desalination projects, specializing in offshore tunneling, brine diffuser design, and energy-efficient systems. His expertise advances sustainable desalination solutions worldwide.