Ceramic Polymer Coating For Drinking Water Applications: Restoration Of Pipework According To Promotec-System

The company Sancor GmbH in Hohenzell/Austria was established in 2007 and is specialized in restoration of built-in pipework systems. The Owner Mr. Veren Nenov and his competent team use the Promotec-system from the Swiss enterprise Promotec Service GmbH successfully, which is a unique and patented procedure for the cleaning and coating of defective pipes without extensive and costly replacing.

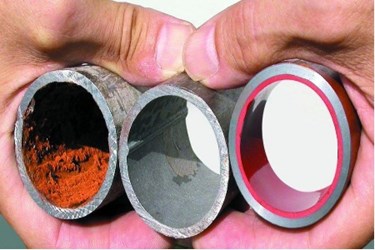

First of all, corroded and calcified pipes of steel and copper for e. g. drinking water, gases, sprinkler installations or compressed air with a diameter of 5 mm up to 75 mm are cleaned by the special wet cleaning treatment gently and thoroughly. By flushing in both directions with fine, swirling washing particles the complete inner surface is being reached and smoothed down properly. No shadow zones occur where rust could remain and spread out afterwards. After mechanical drying the pipes are coated internally with a seamless layer. The application is achieved by a pressure assisted vacuum process. After curing the coating result is examined with a flexible endoscope.

For the restoration of drinking water pipes Sancor GmbH uses continuously our premium system Proguard CN 200, which provides superior physical properties in comparison to other epoxy coatings. Thus, our product is optimally qualified for this specific field of application.

Deciding reasons to employ Proguard CN 200 for these special applications:

-

Drinking water approval (KTW - German stan-dards)

for operating temperatures up to 85°C therefore applicable for hot water pipes. -

Passed test series DVGW-W270 (German standards)

Growth of microorganisms, biofilm. Proguard CN 200 is even in microbiologigal aspects suitable for drinking water applications. -

Low viscosity

after slightly warming the product is adequately free-flowing, spreads easily and evenly all-over inside of the pipework, achieves constantly excellent results in final examinations. -

Fast curing times

already after 24 hours of curing the pipe can be controlled and flushed.

About Ceramic Polymer GmbH

The Ceramic Polymer GmbH produces high-performance coatings with integrated micro ceramic particles for different fields of application. The properties of the ceramic – chemical resistance, abrasion resistance and weathering stability – justify the high quality of our coating systems. By extra integration of microscopic special particles, we generate coating products which provide the highest protection properties. We invest constantly in specific test series to provide high quality, solvent-free coatings and guarantee the safety for drinking water and food applications. The necessary criteria of the German Federal Health Office are fulfilled in different groups. Thus, our products are usable in scope of drinking water (German standard KTW). They show for instance hardly verifiable chlorine absorption or release of substances, which would promote microbiological growth and impair the drinking water.

Source: Ceramic Polymer GmbH