10 Water-Tech Winners From WEFTEC 2017

By Kevin Westerling,

@KevinOnWater

For the second straight year, the Water Environment Federation Exhibition and Conference (WEFTEC) came to McCormick Place in Chicago, returning also to the city which launched WEFTEC 90 years ago. As always, it was a showcase of the latest technologies and ideas available in the water/wastewater industry, but each show also has its own "feel" that reflects the times.

For the second straight year, the Water Environment Federation Exhibition and Conference (WEFTEC) came to McCormick Place in Chicago, returning also to the city which launched WEFTEC 90 years ago. As always, it was a showcase of the latest technologies and ideas available in the water/wastewater industry, but each show also has its own "feel" that reflects the times.

This year, I sensed a bit more optimism in the air as compared to recent shows. Years of underfunding (and a slow overall economy) combined with challenges both immediate and looming can have the effect of bogging down morale, but then there's the defiant about-face — that "pull yourself up by your bootstraps" moment of confronting challenges with vigor. I believe the industry has reached that moment.

Funding remains an issue, as does failing and vulnerable infrastructure, water scarcity, and potential for contamination. Labor is yet another issue, as plant operators hand the proverbial keys over to a generation of workers with knowledge sets that are very different (not to say better or worse) than their predecessors. But rather than bemoaning the changes and challenges, the industry is rallying around solutions, including technologies geared toward energy efficiency, resource recovery, and automation — all of which are necessities for the times ahead, finally being recognized as such.

Here are a few of the technologies from WEFTEC that I found to be impressive and important for keeping utilities a step ahead of our collective industry challenges.

MPC-Buoy by LG Sonic B.V.

One of the biggest challenges, for both wastewater and drinking water facilities, is the prevalence of nutrients in the environment. It has been an ongoing fight to keep excess nutrients out of surface waters, where it leads to the growth of harmful algal blooms (HABs) and toxins that can get into drinking water. Wastewater treatment plants are sometimes held to strict discharge limits, or a “watershed approach” may be used to consider all sources of nutrient pollution, including nonpoint sources such as agricultural runoff. Preventative measures are often taken in vain, complicated by competing interests and shifting of blame, so a practical solution is to treat the problem in the watershed.

The floating MPC-Buoy reduces algae by up to 90 percent and prevents new growth for areas up to 1600’ in diameter. It is an environmentally-friendly solution that controls algae through ultrasonic sound waves, rather than chemicals, and is solar-powered. It’s also a water quality monitor which collects data every 10 minutes, informing an ultrasonic program to treat and prevent algae based on current and predicted water quality/algae conditions. The award-winning technology, from Dutch company LG Sonic, is also safe for fish, plants, and other forms of aquatic life.

AquaGen System by AquaGen Infrastructure Systems, Inc.

It may seem odd that algae, being so troublesome in certain areas, can also be of great benefit to the environment and wastewater operations in particular. AquaGen has created a multistage algae wastewater treatment process that cultivates algae specifically to “super-saturate” the water with oxygen; the algae is then separated out, and the oxygen-laden water is used for biological treatment that eliminates the need for aeration and the expense of blowers. The recovered algae is a valuable resource that can be turned into fertilizer or fuel.

The algae-based treatment solution can be added to existing schemes to reduce nutrient effluent levels and operating costs, or it can be included as part of AquaGen’s complete solution, which also includes an upflow anaerobic sludge blanket (UASB) process to remove up to 75 percent of the organic load at the headworks, thus reducing biological oxygen demand in secondary treatment, as well as other innovative features along the treatment train.

The Enviroprep (EP) System by Anue Water Technologies

Municipalities in charge of many lift stations, especially those with a high density of restaurants in the area, routinely deal with buildup of fats, oil, and grease (FOG) that results in pump failures, sewage backups, and odor issues. There a few ways of handling FOG, including manual cleanouts and regular visits by vacuum trucks. As an alternative — one designed to eliminate the ongoing time, labor, and expense of the aforementioned non-technical solutions — the Enviroprep (EP) System “conditions” the lift station by dispersing recycled discharged wastewater, cycling on and off according to flow conditions. The agitation breaks up FOG and prevents the buildup of bioorganic matter and sulfide-producing slime layers.

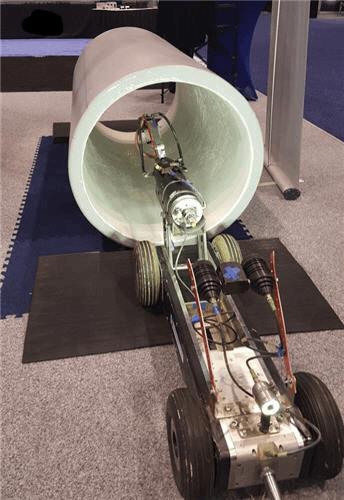

360Ringtech Robotics liner technology by Nukote Coating Systems International

Out in the distribution network, the condition of our conveyance systems has been a major topic for years, with repair or replacement of pipeline infrastructure a major strain on labor and budgets. Regardless of what runs through the pipes, Nukote offers a lining solution — such as elastomeric liners, structural liners, and spray foams — as well as an innovative application process.

Nukote sends robotic crawlers, capable of 360-degree rotation, into the pipe (20” to 144”) to apply the spray liner from manhole to manhole, up to 700 feet at a time. There are liners and robots for most all drinking water, wastewater, or industrial applications, providing up to 50 years’ worth of protection.

MicroNiche Engineering (MNE) by WesTech Engineering, Inc. | Microvi Biotech, Inc.

These biocatalysts, or engineered polymer microorganism composites, are based on Microvi’s biomimetic water technologies and marketed exclusively within the U.S. and Canada by WesTech. The innovation is customized biological treatment for wastewater or drinking water (NSF/ANSI 61 certified), with each shipment of biocatalysts packed with microorganisms that provide optimal treatment for whatever contaminants are identified for removal. They work faster and in a smaller footprint than non-customized biological solutions because they are so effective, with no bulking or foaming and little to no biosolid byproduct. The process starts up in days, compared to the customary weeks or months, and the biocatalysts work for up to 10 years — even through variable flows and conditions — because the microorganisms can survive extended periods of time with no food source.

Some MNE developments in use include Denitrovi for nitrate, nitrite, and perchlorate; Aerovi for “nearly any organic compound” and ammonia removal; Nitrovi for conversion of ammonia into nitrite; and Provi for phosphorus removal and recovery.

Low-energy water extraction technology by Aquafortus Technologies

Aquafortus is a newer company from New Zealand, arriving at WEFTEC for their showcase within the Innovation Pavilion, which essentially prequalified it for this list. However, even among its Pavilion cohorts, the Aquafortus solution — in fact, a “switchable polarity forward osmosis draw solution” — stood out. Designed for industrial wastewater treatment and water recovery, the process is said to reduce energy use by up to 95 percent and trim operational costs by as much as 60 percent. The switchable polarity refers to a transition from salty ionic liquid to an oil state, triggered by raising or lowering the temperature by 1 degree Celsius. The salty state draws water into itself, thereby stripping water out of wastewater. The oil state repels water, so the water drops out of the draw solution for disposal or reuse.

While the promise of forward osmosis has been largely unfulfilled, Aquafortus invites an objective assessment of its technology through a Process Development Kit (PDK), which allows facilities to adjust key parameters such as the membrane, draw solution, cross-flow velocity, flow rate, and temperature to test suitability for a particular waste stream/application and compare the results to competing technologies. The Aquafortus solution can be scaled to any size — currently being pilot-tested at numerous locations — and is particularly suited for chemical refineries, food & beverage facilities, coal-fired power plants, and oil & gas operations.

Radar measurement Time-of-Flight Micropilot FMR10/FMR20 by Endress+Hauser

The latest innovation from the venerable instrumentation company Endress+Hauser is Bluetooth capability for its FMR10 and FMR20 radar measurement devices. Now operators can view signal curves and perform remote operations on any Bluetooth-enabled smartphone or tablet (iOS/Android) through the convenience of the SmartBlue App. Or, if preferred, the traditional 4–20 mA HART communications protocol can be utilized. Either way, these two-wire, non-contact devices earn their value with a low price point — starting at $550 for the FMR10 with a measurement range of 26’, according to Alan Vance, E+H’s Industry Manager for Water/Wastewater. The FMR20 offers maximum measurement distance options of 33’ or 66’, with corresponding price points from $600 to $1150. (Vance informed me that the “typical” price range among competitors is $1800-$2000.)

For use across a variety of industries, water/wastewater applications include chemical storage, water tank, and lift station level measurements.

ftServer by Stratus

As systems get more technologically advanced at water and wastewater facilities, control systems take on more responsibility — and risk. Information servers are the backbone of modernized operations, from supervisory control and data acquisition (SCADA) and automation to the Industrial Internet of Things (IIoT). However, this transition can give pause to operators wary of control system malfunction and/or O&M requirements. The Stratus ftServer provides solace through system reliability based on built-in redundancy (two servers running continuously), as well as operation that requires zero IT expertise.

When the ftServer detects a hardware or software issue, it automatically orders a new part. The part generally arrives the next day, according to John Fryer, Stratus’ Senior Director of Industry Solutions, and can be simply swapped out. Only the slightest of upfront training is required to perform the maintenance procedures, which are rudimentary by design. All the while, the second server ensures that operations are never interrupted and no data is lost or compromised.

Godwin NC150S Dri-Prime Pump by Godwin, a Xylem brand

Godwin has been around for 152 years, since 1865, with a name and pump that is as established as any in the business. Its stalwart dewatering line, the Dri-Prime series, added a new member with the unveiling of the NC150S at the very opening of the WEFTEC exhibition. During the presentation, Mike Ramos, Director of Engineering for Xylem Dewatering, described the latest evolution of the Dri-Pump as an improvement on four fronts: pumping efficiency, peace of mind, fuel economy, and ease of maintenance. The standout innovation, however, is the “smart” capability of the pump, allowing it to be remotely monitored and controlled via smartphone, tablet, or computer. Per Ramos:

- Pumping efficiency was improved by incorporating the N-technology self-cleaning impeller borrowed from Xylem’s Flygt brand;

- Peace of mind comes from its Field Smart Technology (FST) — i.e., its smart capability;

- Fuel economy was boosted by 10 percent, with emissions reduced by 90 percent; and

- Maintenance was “reimagined to take less time and effort” — for example, a compressor belt change takes just 30 minutes.

MultiCore Turbo blower by Aerzen USA

Last year it was just a concept, but now it’s a reality for Aerzen — a blower that is powerful enough, at 800 hp, to meet the high airflow demand requirements (up to 20,000 cubic feet/minute [CFM]) of large wastewater treatment plants. Designed with the U.S. market in mind, Aerzen supports their new offering with U.S. engineering and parts/service availability. One very essential part of the blower is the air foil bearing, which was described to me in detail by Tom McCurdy, National Sales Manager for Aerzen's Environmental Group. The bearing design prevents moving parts from coming into contact with each other, protected by a microns-thick cushion of air. If a hard stop occurs, the bearings are able to withstand contact from the rotor “over and over and over again.”

In theory, however, hard stops should be rare, thanks to the MultiCore’s idle mode feature. Instead of shutting down completely during times when no air is needed, the system slows to 10,000 rpm — “like putting it in neutral,” McCurdy explains — thus saving energy while remaining ready to reengage.

For more on WEFTEC 2017 innovation, check out this archive of Water Talk conversations with technology providers and industry experts, recorded live from the show floor.