WASTEWATER FILTRATION RESOURCES

-

This application profile focuses on two test sites with different treatment requirements and describes how Aqua-Aerobic Systems’ OptiFiber® pile cloth media filtration was used at both sites to address the removal of harmful constituents from refinery wastewater.

-

Learn about filtering microplastics from industrial wastewater prior to discharge, and how this is one way to effectively reduce the volume of this waste material from entering our surface water.

-

Read about the cloth media filter installations that have been operating in food and beverage wastewater plants for over 25 years.

-

This application note will explore installations of AquaSBR Systems worldwide in a variety of municipal and industrial applications.

-

In this case study, read about an underdrain system that continues to operate as expected after 16 years of operation and appears to be in perfect condition.

-

Read about the $568 million, decade-long upgrade of a Water Pollution Control Plant that would expand the plant’s capacity from 30 mgd to 40 mgd while also reducing nitrogen and phosphorous to the limit of technology.

-

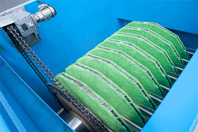

Discover how Disc Filter increases filtration capacity and performance in a small footprint.

-

Automated scraper strainers pre-filter water and wastewater to protect fragile membrane systems from damage caused by large, suspended particles, reducing maintenance and replacement costs.

-

Regulating the discharge of phosphorus from industrial and municipal wastewater treatment plants is a primary factor in averting the eutrophication of surface water sources. Phosphorus is one of the key nutrients that contribute to this process in both lakes and natural waters. Its existence has caused major water quality issues such as the diminished recreational value of these surface waters, increased water treatment costs as well as the potentially lethal consequences of mycotoxins from algal growth.

-

Last Dollar is a year-round residential community located just outside of Telluride, Colorado. The facility had been reliant on an aging treatment system that was failing quickly and needed immediate replacement to prevent operational fines. The current technology would not meet the new and more stringent effluent requirements in Colorado, so the project had to be completed quickly and within a tight budget. AquaWorks DBO provided the permitting and site engineering support to ensure the project was completed in 8 months from contract award to system operation.