WASTEWATER DISINFECTION RESOURCES

-

This paper presents a comprehensive overview of technologies for phosphorus removal and recovery, including chemical and biological processes, ballasted clarification, filtration, and nutrient recovery.

-

In order to improve the treatment performance (because of the continued cost to maintain compliance), and ensure that it would eventually have the treatment capacity to meet future population growth equivalent of up to 225,000, Swansea WwTW was in need of an equipment upgrade.

-

When it comes to choosing a wastewater treatment strategy for a specific water issue, facility managers often start by asking themselves what the best technology is for addressing their contaminant. However, there are far more important questions that need to be answered first.

-

For years, conventional activated sludge (CAS) has been the default in wastewater treatment. But the industry is changing.

-

Discover how an agency balanced effective disinfection while minimizing environmental impact and ensuring the safety of both the public and workers in its wastewater treatment practices.

-

Managing pH in wastewater treatment is a crucial undertaking for water utilities. Solid contaminants often receive more attention, as they're more obvious threats, but sub-optimal pH levels can be dangerous, too.

-

See how an Israeli hotel chain slashed energy costs by 27% while ensuring Legionella compliance through innovative UV water disinfection technology.

-

Learn how High Desert Milk, a cooperative in Idaho, optimized their water treatment process using HOD™ UV technology, ensuring FDA compliance while significantly reducing water and energy consumption.

-

An Atlantium HOD™ (Hydro-Optic Disinfection) UV system was installed at the outlet of a PW tank to serve as the primary disinfection barrier, with water circulating through the system at 6m³/hr before reaching the points of use.

-

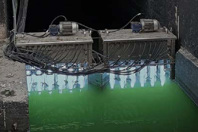

A power plant in Pinghu, Zhejiang Province in China needed to replace the use of chemical biocides and protect boiler feed make-up water from anaerobic and aerobic bacterial growth and associated biofouling.

ABOUT WASTEWATER DISINFECTION

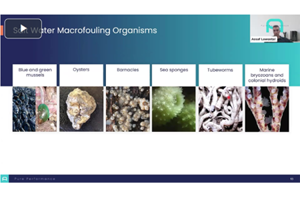

Wastewater disinfection takes place after primary, secondary and sometimes tertiary wastewater treatment. It is typically a final step to remove organisms from the treated water before the effluent is released back into the water system. Disinfection prevents the spread of waterborne diseases by reducing microbes and bacterial numbers to a regulated level.

A variety of physical and chemical methods are used to disinfect wastewater prior to it being released into natural waterways. Historically, the chemical agent of choice for municipal wastewater treatment has been chlorine, due to its disinfecting properties and low cost. However, the rising cost of chlorine and concerns that low chlorine concentrations can still be toxic to fish and other wildlife, has given rise to more physical methods of wastewater disinfection being adopted such as ozonation or ultraviolet (UV) light.

The use of ozone as a disinfection agent has the added benefit of increasing the dissolved oxygen content of the treated wastewater. However, because the ozone has to be generated, ozonation can require prohibitive up-front capital expenditure compared to traditional chlorination. UV disinfection has been growing in popularity as a wastewater disinfection method, in large part because of the life-cycle economics of the equipment and the fact that, like ozone, there is no toxic residual.