|

From its inception in 1967, Sanitaire has focused on creating innovative wastewater treatment solutions for municipal and industrial wastewater treatment applications. Sanitaire is a leader in diffused aeration systems, advanced SBR and Advanced Oxidation Ditch technologies and certified DrumFilter tertiary filtration systems for municipal and industrial facilities. Our process knowledge allows us to provide solutions that not only save capital and operational costs, but last long and minimize the total cost of ownership. |

||||

|

|

|

||

| Sanitaire Aeration System Video | Brochure: Sanitaire ICEAS® Advanced SBR Technology | OSCAR™ Process Performance Optimizer | ||

CONTACT INFORMATION

Sanitaire -- A Xylem Brand

4828 Parkway Plaza Blvd. Suite 200

Charlotte, NC 28217

UNITED STATES

Phone: 414-365-2200

Fax: 414-365-2210

FEATURED ARTICLES

-

Sanitaire has an array of digital solutions that focus on asset management as well as energy/process optimization. In this presentation, we discuss these solutions in detail and outline how these products can improve CAPEX budgeting plans and improve preventative maintenance through diffuser health monitoring. In addition, we expand on how Sanitaire’s new offerings can save on OPEX with specialized energy saving software that optimize the aeration process.

-

Xylem, the leader in biological wastewater treatment technologies, is introducing its new Sanitaire Digital Pressure Monitor (DPM) to transform wastewater diffusers into smart diffusers. The Sanitaire DPM maximizes diffuser operation and increases energy savings through strategic fine-bubble aeration system monitoring and intelligence. The solution offers users an enhanced digital interface that provides diffuser health data, engineering and economic calculations, and asset management recommendations.

-

Sanitaire presents best practices and steps for how to evaluate and maintain diffused aeration grids.

-

Cut your daily energy consumption with the Sanitaire Aeration System. It's the optimal design to supply oxygen at the lowest possible energy cost.

-

Stricter nitrogen and phosphorus permits, pressure to reduce energy and chemical usage, limited time and staff. These days, operators are required to do more with less. How could these challenges be met without a plant reconfiguration?

ABOUT SANITAIRE -- A XYLEM BRAND

Sanitaire - A Xylem Brand is the world leader in diffused aeration and advanced biological treatment technologies. Beginning in 1967 Sanitaire® products have been used to create innovative wastewater treatment solutions for municipal and industrial wastewater treatment applications. Sanitaire® equipment and technologies are the industry standard and have been installed in thousands of communities and industries throughout the world.

Sanitaire® aeration systems provide high oxygen transfer that results in energy efficiency and cost savings for customers. We provide extensive application support to ensure you select the right product with optimized design. Our wide selection of diffuser technologies includes the age resistant Silver Series membrane disc, the durable ceramic disc diffuser available with in-situ cleaning, as well as various coarse bubble technologies.

Our advanced Sequencing Batch Reactor (SBR) technology is a complete biological treatment solution for municipal wastewater treatment and select industrial treatment applications. This innovative and cost effective treatment process can be configured for Biological Nutrient Removal (BNR) and the most stringent effluent requirements. In addition to traditional SBR technology, Sanitaire® recommends the superior flexibility of the ICEAS® (Intermittent Cycle Extended Aeration) design, which does not require any flow diversion and offers smaller basin volume, single basin operation and uniform basin loading. The Sanitaire® ICEAS process provides continuous inflow in a single basin, even during settle and decant phases of the operating cycle.

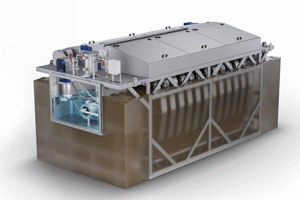

Sanitaire® Drum Filters offer a cost effective, low energy tertiary treatment that only requires power during the backwash cycle. Our corrosion resistant components are low maintenance and can easily be added to new or existing installations.

Contact us today and allow our experienced applications team to design a customized treatment solution for your needs.