Views From The Top: Will Dow's Breakthrough Revolutionize Water Treatment?

By Kevin Westerling,

@KevinOnWater

A Q&A with Snehal Desai, global business director for Dow Water & Process Solutions, about the power of RO (reverse osmosis) membrane technology — to provide cleaner water, save precious resources, and improve sustainability.

Way back in 2006, Dow set a goal to create a “breakthrough” technology to combat the challenge of water scarcity by 2015. Before the clock struck midnight, Dow announced a new RO membrane element that, according to the company, follows through on that promise. Such impact is predicated on full adoption, however, and that requires convincing. I talked with Snehal Desai of Dow to understand just how unique and game-changing the technology is — or could be. Read on and decide for yourself.

Dow pledged three “breakthroughs to world challenges” by 2015. One challenge was water scarcity, and FILMTEC ECO RO is your breakthrough. How so?

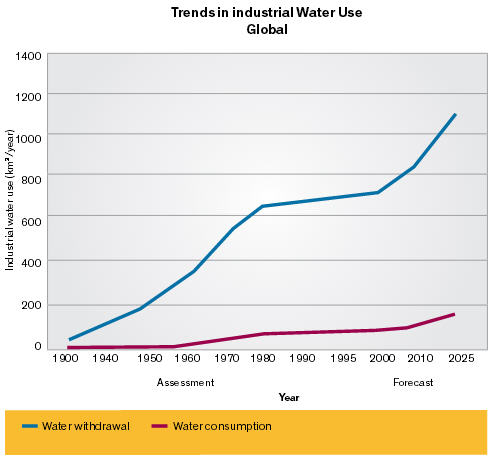

The industrial use of water is one of the largest uses of treated water. Manufacturing sites require reliable water utility — matching the water-quality specifications needed for their products — as well as chemicals to run their water purification systems. Increasing water scarcity, however, has driven companies to seek out new ways to purify water that are both cost-effective and environmentally conscious. While the price of water is increasing, access to good quality water in close proximity to factories is decreasing, especially in areas suffering from natural water scarcity.

One effective solution is to treat various water sources, and even reuse and recycle wastewater. FILMTEC ECO RO elements offer unparalleled salt removal, solids rejection, and flow performance (99.7 percent at 150 psi) for industrial water needs, producing demineralized water from contaminated water sources such as surface water, groundwater, treated wastewater effluent, well water, or tap water. As this new technology is fully adopted, we anticipate it will help produce 10 billion cubic meters (m3) of clean water, while providing more than 2 billion kWh of energy savings and reducing carbon dioxide (CO2) emissions by 1.5 million metric tons in its first 10 years of use alone.

This innovation will help deliver a more sustainable water supply to the world, addressing global water scarcity in a very tangible way.

Do you anticipate full adoption? Will these capabilities compel more treatment plants to adopt RO and the related capital expenditure?

Globally, RO membrane treatment is likely to continue at nearly 10 percent compound annual growth from 2008 to 2015, of which industrial wastewater applications are already on the rise. Increasing production volume and technological improvements have reduced the capital and operating costs of membrane systems to the point that membrane treatment is now seen as a viable alternative in many water and wastewater applications.

Globally, RO membrane treatment is likely to continue at nearly 10 percent compound annual growth from 2008 to 2015, of which industrial wastewater applications are already on the rise. Increasing production volume and technological improvements have reduced the capital and operating costs of membrane systems to the point that membrane treatment is now seen as a viable alternative in many water and wastewater applications.

FILMTEC ECO elements can help deliver up to 40 percent better water purification while using up to 30 percent less energy, resulting in up to 19 percent less operating costs. For example, Dow developed an innovative two-pass RO design to optimize a power station’s existing configuration in Alberta, Canada. The design includes FILMTEC ECO 440i RO elements and FILMTEC XFRLE-400/34i RO elements. Since their installation, the elements have resulted in a 30 percent energy savings in the system’s second pass, and improved overall pressure drops and fouling.

An analysis of the economic value of FILMTEC ECO over the lifetime of the element shows that chemical and energy savings are significant compared to standard products. Dow has taken this additional value and shared it with its customers.

How has Dow addressed the long-standing issues associated with RO, namely energy requirements and membrane fouling?

The building blocks of FILMTEC ECO elements are an advanced, thin-film polyamide membrane chemistry and a new, low-pressure-drop feed spacer configuration to maximize performance.

New membrane chemistry allows for a new kind of water treatment plant to emerge — one that runs on less energy, operates more efficiently due to fouling resistance, and reduces environmental impact.

FILMTEC ECO’s new membrane chemistry provides high salt rejection at lower pressures than previously possible, while the new feed spacer is variously deployed to provide either low membrane fouling, low pressure drop, or high packing density. This innovation offers the possibility of higher rejection of salts at significantly reduced operating pressures and reduces energy consumption and ion exchange regeneration costs for downstream operations through improved hydraulic balance and lower feed pressure.

How do the space and O&M requirements compare to conventional RO systems?

In some systems, operators can reduce or completely eliminate the need for a second RO pass, since higher-quality permeate is retained on the first pass. Depending on water quality requirements, conventional RO elements can either provide high rejection or low energy. By contrast, FILMTEC ECO elements can provide both high rejection and low energy, resulting in operational savings of up to 19 percent.

You’ve compared FILMTEC ECO to “conventional RO,” but how does the technology compare to other recent membrane advancements including forward osmosis and ceramic membranes?

Forward osmosis, next-generation ceramic membranes, and newer technologies such as membrane distillation and electrodeionization are in earlier stages of commercialization, and typically apply to niche applications. FILMTEC ECO is a proven, breakthrough filtration and separation innovation with wider application.

Are the applications the same as with typical RO? Do the new elements create new opportunities for reverse osmosis?

FILMTEC ECO RO elements can be used in multiple applications where RO is typically used, including (but not limited to) industrial cooling and boiler water, tertiary wastewater purification for discharge or water reclamation, municipal drinking water production, and seawater desalination as a second-pass purification membrane. The elements are an excellent choice for new RO installations and replacement systems, facilitating improved energy efficiency across a broad temperature range, and they can help create highly compact, energy-efficient operations with long-lasting performance for mobile units.

Globally, FILMTEC ECO is gaining adoption in a wide range of industries. In the power industry, the elements are helping to improve uptime and reduce chemical use for utility providers. In the ultrapure water industry, they are helping to increase the rejection at lower feed pressure to accommodate increasing needs for electronics manufacturing. The beer and beverage industry is saving on energy use and chemical use and increasing capacity by improving uptime.

Do you anticipate more overall impact in the industrial market, rather than the municipal market? What obstacles would be present in penetrating the latter?

A high-performance membrane can be successfully applied in both the industrial and municipal market; however, it is more readily adapted in the industrial and wastewater segments due to specific footprint, energy, and quality initiatives or requirements. Depending on the system parameters, FILMTEC ECO may be beneficial in municipal applications, but it may also exceed water quality and energy efficiency specifications. In other words, a singular, low-energy element may meet system requirements in some municipal systems.

Are the membranes compatible with RO skids from competing suppliers? How do you feel about standardizing membranes/elements for consumer flexibility?

RO is a standardized industry today, especially as it relates to the industrial and municipal market. In this case, FILMTEC ECO elements are compatible (typically 4” and 8” membranes), making it ideal for replacement and new construction markets.

Why did Dow name water scarcity among its pressing “world challenges”?

By 2030, under an average economic growth scenario and without efficiency gains, global water requirements will grow from 4,500 billion cubic meters today to 6,999 billion cubic meters — a 50 percent increase in just two decades. Analysts predict that available water supplies will satisfy only 60 percent of demand as population, urbanization, and higher living standards continue to rise. To this end, Dow is committed to developing product innovations and technologies that help meet growing global demand for safe and available water resources across the globe.

Municipal dollars are limited, and there are many competing needs. How does Dow address affordability in this cost-conscious climate?

FILMTEC ECO is designed for the high purity, low-energy space. With that said, an analysis of the economic value of the technology over the lifetime of the element shows that chemical and energy savings are significant compared to standard products. In this sense, total cost of ownership of a system, including its elements, needs to be taken into account when examining options. For example, system size, footprint, chemical costs, and more can be determined through a system evaluation to reduce total cost of ownership. Also, with a financing partnership through De Lage Landen Financial Services, Dow can now offer RO elements on lease, allowing customers to transfer capital expenditure into operational expenditure. Customers typically have long capital-planning and funding cycles, so this option presents a level of flexibility for Dow and its customers.