10 Technology 'Treats' From WEFTEC

By Kevin Westerling,

@KevinOnWater

A roundup of some of the most impressive products showcased at one of the world’s largest water quality events

October reminds me of two things: Halloween and WEFTEC — both bearing treats aplenty. While you likely have little interest in my choice of costume or candy for this year, I do hope the WEFTEC “treats” compiled below satisfy your appetite for new, interesting, and useful water technologies. Though WEFTEC is mainly a wastewater show, it bills itself as “The Water Quality Event” and certainly has reach beyond strictly wastewater. That fact is reflected in the selections below; I tried to offer something for everyone to sink their teeth into (and here ends the Halloween puns). Enjoy!

THK Series Thickening System — Centrisys

A natural place to start when reporting on the most innovative technologies at WEFTEC is with the award winners. The Centrisys THK Series thickening centrifuge won a 2013 WEF Innovative Technology Award — but I had to see for myself, knowing that sludge-handling solutions are very much sought by utilities. The THK Series did not disappoint.

The advantages over standard dissolved air flotation (DAF), gravity belt, or rotary drum thickening technologies include: small footprint, zero need for polymer, cake solids up to 10 percent, an enclosed design (less odors), and energy efficiency. The THK Series requires about 1,000 sq. ft. of space (equaling the capacity of two DAF systems at 5,000 sq. ft.) and 50 percent less power (0.11 kW per gal. per min.) than DAF. By sending less water to the digester, it reduces the amount of supernatant and heating demand, at the same time freeing up more digester gas for possible on-site heating. Feed capacity for the THK is 100 to 1,000 GPM.

The THK thickener was trailer-mounted on the tradeshow floor.

According to Josh Grable, the Centrisys process engineer whom I spoke to at the booth, the money saved on polymer, energy, installation, and O&M amounts to payback period ranging from zero to five years. It handles the following sludge types for municipal applications: primary, secondary (waste activated), oxidation ditch, digested, and MBR (membrane bioreactor).

LEAPprimary MBR — GE Power & Water

Speaking of MBR, GE made a splash at the show with the introduction of its LEAPprimary system, designed specifically for pretreatment at MBR facilities. By combining separation, thickening, and dewatering into one process, space requirements can be reduced by up to 90 percent; conventional clarification and fine screening is no longer needed.

LEAPprimary is part of GE’s total MBR solution.

Performance-wise, LEAPprimary removes 50 to 70 percent of total suspended solids (TSS) and 25 to 40 percent of biochemical oxygen demand (BOD). Furthermore, solids dewatering gives 20 to 30 percent dry matter, thereby reducing handling costs. Energy savings are also realized due to the solids and organics being removed prior to secondary biological treatment. Meanwhile, the recovered organic material is bio-available for wastewater-to-energy processes. All that, plus the significantly important protection of your membranes.

The Duet Screen — Ovivo

Combining multiple systems into one is a worthy trend — operational efficiency is paramount these days — and Ovivo’s Duet screen is another prime example of this idea at work. While MBR facilities will typically need a second filter unit to reduce fibrous waste and membrane fouling, the Duet incorporates its fine (3 mm) and finer (500 to 1,800 µm) screens in the same drum. It works with gravity or pumped-flow applications, in a channel or its own box, and also provides grit removal. Peter Bugg, director of municipal marketing for Ovivo, also touted the dual-aperture, flow-through screens for their low headloss.

Best of all, you’re buying one screen instead of two.

The Ovivo twofer: primary and secondary screening in one unit

BioMag System — Siemens Water Technologies

A full 25 percent of the technical program at WEFTEC was devoted to nutrient removal — a reflection of need in the industry as discharge limits for phosphorus and nitrogen continue to get broader and stricter. Of all the nutrient removal technologies I’ve heard about and covered, BioMag stands out as striking — at least on video (see below) — for its rapid separation ability. For use in biological nutrient removal (BNR), BioMag’s effectiveness comes from magnetite, which is infused as a ballasting agent to increase the secondary settling rate of biological floc in the clarifier. The real game-changing aspect of this treatment, however, is that it can triple a plant’s capacity and help it achieve enhanced nutrient removal (ENR) without increasing footprint. Achievable nutrient reduction levels with BioMag are rated at less than 0.2 mg/L for total phosphorus (TP) and less than 3.0 mg/L for total nitrogen (TN).

The close cousin of BioMag is CoMag, which uses the same magnetite ballast to enhance chemical treatment at the primary and tertiary stages. With CoMag, TP can be dropped to less than 0.05 mg/L. A very cool feature of both, by the way, is that magnets (more or less) can be used to recover 95 percent of the magnetite for reuse.

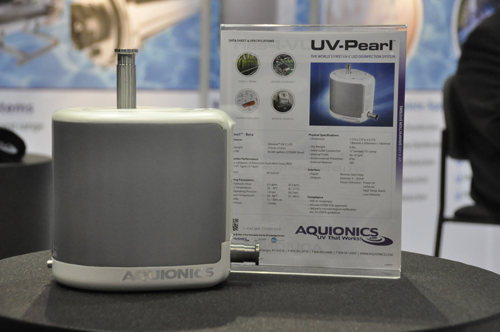

UV-Pearl — Aquionics

Switching gears from big equipment to small, the UV-Pearl from Aquionics is a compact, UV LED disinfection system designed for flows of less than 5 gallons per minute (gpm). It mostly finds application in the food, beverage, and pharmaceutical/healthcare industries for process water loops, ultrapure water generation, and medical sterilization.

Powerful technology in a small (7.5"h x 7.9"w x 6.3"d) package

Though it may be a smaller-scale, niche technology, it has a set of differentiators that land it on this list. First, the system was rated five times more efficient than conventional disinfection systems in studies by the University of North Carolina and University of Colorado. Working in the deep UV spectral (UV-C) range, it can be tuned to different wavelengths (240 to 280 nanometers) to allow for targeting of specific pathogens. It’s also mercury-free, which isn’t the case with conventional systems. Lastly, it runs on low power (50 milliwatts) with near-instant (nine nanoseconds) on-off capability, making it ideal for batch processing.

i::scan Spectrophotometer — s::can

I discovered even more innovation in the world of LED technology at the s::can booth. The Austrian company with the unusual name claims to have technology that will “revolutionize” the industry, and I’m not sure I disagree. s::can’s new multiparameter spectrophotometer can be installed directly into distribution pipes, withstanding pressures up to 10 bar and requiring minimal maintenance. More impressive, however, are the measurement parameters of this miniature probe. The i::scan offers readings on nitrate, hydrogen sulfide, and ozone — typical of simple photometers — but also measures turbidity, UV254, total organic carbon (TOC), biochemical oxygen demand (BOD), and color, due to its multiple wavelengths.

The i::scan spectrophotometer is novel for its in-pipe capability.

Where s::can hopes to really make waves, however, is with pricing. According to the company, the breakthrough design of the probe brings the price point down to that of simple photometers, allowing small water utilities and unmanned plants to reap the benefits of a high-capability spectrophotometer. For larger and/or more advanced utilities, the probes can be also be used as part of a smart-grid water network.

Packaged Lift Station w/SEG Grinder Pump – Grundfos

Designed for decidedly out-of-network wastewater applications — rural areas without gravity sewage systems — Grundfos packaged lift stations are easy-install solutions to potentially messy situations. The polyethylene housings come in a variety of sizes (32” to 67” wide and 60” to 118” high) and can accommodate two SEG grinder pumps. The pumps are also versatile, available with high-pressure/low-flow or high-flow/low-pressure hydraulics. The inner workings of the patented grinder system reminded me of a garbage disposal — but one on steroids, as I watched it tear through a bath towel like it was paper.

The SEG Grinder Pump (right) resides within the Grundfos Packaged Lift Station.

All piping, valves, and necessary components are pre-installed in the units, which also feature a unique design that withstands uplift caused by groundwater levels. Easy and reliable are the stated goals for the system — to just drop it in and forget it.

The PaveDrain System — PaveDrain, LLC

Sometimes it’s the simple-looking items that are most revolutionary, and what could be more simple-looking than a block of concrete? The PaveDrain elicits a double-take, and upon further review — and in hearing about the benefits — it’s apparent that this is no simple stone.

Technically, it’s permeable articulating concrete block/mat (P-ACB/M), recognized by the EPA as a structural best management practice (BMP) for stormwater infiltration. The blocks are interlocking, but at the same time have ¼” of space between them; this allows for infiltration at a tested rate in excess of 4,000 inches/hour per one foot diameter. Each block is a 12” square measuring 5.6” high and weighing in at 45 to 49 lbs. The underside features an archway that provides storage, detention, and conveyance of rainwater. Talking to PaveDrain president Doug Buch at his booth in the Innovation Pavilion, he informed me that future versions will also offer a heating option to melt snow and eliminate the need for salt.

The shape and size of the PaveDrain pavers set them apart.

The PaveDrain System was also tested for heavy loads, stability, and slip resistance, passing on all fronts. Most importantly, water goes where it should — in the ground — rather than overwhelming the streets and sewers.

EXO2 Water Quality Sonde — YSI

While ocean water quality may have been less of a concern to WEFTEC attendees than inland waters, it is nonetheless an important environmental issue. Plenty of instrumentation companies can address the problem, but only one was recently featured in a national television commercial. See the YSI EXO2 highlighted by Verizon below (noting the 10-second mark):

When I visited the YSI booth, they were rightly proud of the spot, and of the product. The EXO2 water quality sonde is a multiparameter instrument with six user-replaceable sensors, a central wiper to prevent biofouling, and an integral pressure transducer for depth. It’s not just for the ocean, however. More appropriate to the masses at WEFTEC, the EXO2 works in surface water and groundwater to collect data on conductivity and temperature, DO, fDOM (fluorescent dissolved organic matter — a surrogate for colored dissolved organic matter, or CDOM), pH or pH/ORP, total algae, and turbidity.

The EXO2: a six-shooter of sensors

Saajhi Treadle Pump — Xylem

And now for something completely different…

We talk about water scarcity issues here in America, but the situation is literally life and death for much of the world. Water and agriculture are obviously connected to food security, but there is also a time/labor element to optimize — the same way we talk about efficient operations here. The Saajhi treadle pump’s pressurized water delivery (spray or drip) system uses 40 percent less water, with 25 percent less labor, compared to traditional furrow irrigation.

Using no electricity and having very few removable parts (which are field-serviceable, with no tools required), the Saajhi targets the needs of smallholder farmers in poverty-stricken and water-scarce countries. In other words, it can help save lives — at a price of about $200 per unit.

Though it’s serious subject matter, it was a hoot (check out the video) to see the treadle pump demonstrated on the tradeshow floor — among the many interesting sights and sounds that WEFTEC annually provides. Feel free to share your thoughts of the show, or of the technologies featured in this article, in the comments section below.