Benefits Of Remote Access To Primary Wastewater Treatment

By Daniel Theobald, "Wastewater Dan"

A real-world, industrial application of remote process monitoring proves that a little technology can go a long way in terms of cost savings and process improvement.

Remote access may mean different things to different people. It could refer to the way people who work from home access their company's database, or it might mean branch offices of big corporations that need constant interaction with systems at the company headquarters, or it could be mobile workers who upload and download information from almost anyplace.

This case, highlighting an industrial wastewater pretreatment facility in the southern portion of the U.S., represents the last scenario. Remote access is being used to monitor primary wastewater treatment — mainly chemical treatment — for a facility discharging effluent to the local sewer authority.

The setup provides real-time access to all significant operational control points of the effluent treatment process via internet connection. By sharing the static IP address with industry management and the receiving sewer authority regulator, they get continuous real-time access to the critical data points — including pH values, pump running percentages, and flow rates — documenting discharge permit compliance. Both management and the regulator were most energized to be able to monitor, in real time, discharge pH to the sewer.

For the system analyst, however, real-time accessibility is only the beginning. With the custom-designed remote access system, which has been in place for approximately 18 months, information can be downloaded to an electronic device and the data preserved as a workable file for analysis. This allows for reductions to cost components of operations and improved operational quality performance.

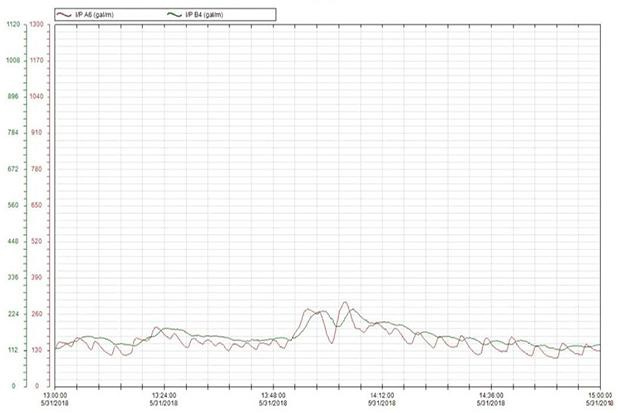

For instance, by using the data in a working interpretative file, flow rate and its effect on critical functional components, such as contact time and chemical usage, can be analyzed.

Analyzing even deeper into the data, containment and containment-concentration fluctuations can be discovered through flow rate variations, also affecting the chemical usage requirement — noteworthy in that chemical usage efficiency is indispensable to cutting operational cost while improving treatment performance.

Operational treatment performance is no better than its most inefficient operational control point. By utilizing the data to pinpoint the absolute most inefficient chemical usage injection location, one can examine its impact along the price and execution of the procedure. At this plant, it was discovered that chemical use was excessive, so immediate action was taken to modify the control set points.

The data was then used to diagnose the second-most inefficient chemical usage injection location and its impact, revealing that this inefficiency was an important catalyst for the chemical overuse at the most inefficient injection point.

Because the first chemical in this case study increased pH and the second chemical decreased pH, overuse of the former triggered overuse of the latter. The inefficiency was rectified at the primary injection point of the chemical used to treat the wastewater, pH control set points were revised, and for certain time frames chemical usage was restricted altogether.

Another significant benefit from the remote, real-time monitoring of wastewater operational controls at this industrial facility was the ability to see and analyze condition changes, even before onsite wastewater operators, allowing for quick contact of on-duty personnel to enact a timely response.

Additionally, the documentation of conditions has helped management to assess manufacturing operations in terms of wastewater impact. Ultimately, the monitoring system disclosed opportunities to introduce other wastewater treatment chemical injection locations that will likely increase chemical efficiency while improving handling performance.

Since the remote access system has been online at this wastewater treatment facility, there have been no discharge permit violations, overall chemical application costs have been reduced by approximately 25 percent, and additional enhancements for cost reduction and treatment performance have been identified.

While operations, applications, and results will vary, the benefits of real-time monitoring for wastewater treatment facilities are easy to see — even (and especially) from afar.

Flow measured at separate locations within the wastewater treatment facility

About The Author

Daniel L. Theobald, proprietor of Environmental Services (TheWastewaterWizard.com), is a professional wastewater and safety consultant/trainer with hands-on industry experience since 1987. He holds numerous certifications from wastewater management regulatory boards and professional organizations and contributed one chapter to the Water Environment Federation’s Manual of Practice #37 (MOP-37), a technical manual resource guide for biological nutrient removal published in 2013.

Daniel L. Theobald, proprietor of Environmental Services (TheWastewaterWizard.com), is a professional wastewater and safety consultant/trainer with hands-on industry experience since 1987. He holds numerous certifications from wastewater management regulatory boards and professional organizations and contributed one chapter to the Water Environment Federation’s Manual of Practice #37 (MOP-37), a technical manual resource guide for biological nutrient removal published in 2013.