10 Stand-Out Technologies From ACE12

By Kevin Westerling,

@KevinOnWater

Among the vast array of products and services showcased at ACE12, there were 10 technologies that stood out for me on the tradeshow floor. The list covers various points of interest in the water cycle, including treatment, plant control, water quality monitoring, distribution, and advanced metering infrastructure (AMI). The commonality is that each technology is very relevant to one or more of the common issues facing the drinking water community today. Here you will find solutions for satisfying U.S. EPA regulations, improving operational efficiency, preventing water loss, delivering better customer service, and more.

Spektron e UV Series

Xylem Inc.

In my trek around the Dallas Convention Center, Xylem’s booth stood out as impressive not only because it won Best of Show in the large booth category, but also because of the level of technology on display. Disinfection and Oxidation Market Manager Jay Jordan presented the latest entry to Xylem’s UV series, the WEDECO Spektron e UV solution, featuring lamps that require 20% less energy and use 80% less mercury than previous generations. There are no byproducts with UV, and the process is said to render 99.9% of all pathogens harmless in seconds — designed to meet all common disinfection requirements, including 3-log Cryptosporidium.

The Spektron e UV series, presented by Xylem’s Jay Jordan

EcoStruxure Solutions For Water And Wastewater

Schneider Electric

With the massive amount of energy required to treat water, there is significant opportunity for savings through optimization, which is why Schneider created the Water Wastewater Competency Center. I spoke with Mark Leinmiller about the multitude of ways a utility can save on energy, and how these many facets come together with Schneider’s EcoStruxure program. EcoStruxure is integrated energy management architecture for piloting, monitoring, and optimizing networks. The intelligence of the system goes beyond merely identifying energy usage in the plant; it provides a means to solve energy inefficiencies, thereby saving time, money, and water.

Attendees test drive Schneider’s EcoStruxure solution.

STAR ZoneScan Automated Leak Detection

Aclara

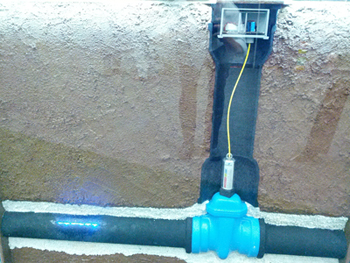

In this time of small budgets and large expenses, municipalities certainly can’t afford to lose water and revenue. To help utilities keep a tighter system, Aclara partnered with Gutermann International to create the STAR ZoneScan leak detection solution. The Gutermann leak-intelligence units — or “loggers” — monitor sound characteristics in the pipeline to pinpoint a leak within a few feet, while Aclara’s STAR Network AMI system collects the data for operators to analyze at the utility office — no drive-by data collection required. In fact, the system requires minimal operator involvement once deployed.

Aclara’s STAR ZoneScan leak detection system in the ground

Deployment requires a logger to be set up at regular intervals throughout the water distribution system. I watched as one of the units was dropped into the (faux) ground and removed again — a seemingly simple process facilitated by a magnet that affixes itself to the pipe valve. Voilà… full system visibility.

BioMag And CoMag Clarification Systems

Siemens Water Technologies

Siemens introduced a very novel water and wastewater treatment technique at ACE12 — BioMag and CoMag technologies, obtained through the acquisition of Cambridge Water Technologies in early 2012. The unique aspect of the systems is the use of magnetite, which is added as a weighting agent to the biological or chemical floc, improving the rate and reliability of solids-liquid separation in clarifiers. The process is also economical in that the magnetite can be recovered and recirculated into the treatment process.

A view of Siemens’ new clarification process

As for applications, BioMag is intended for biological wastewater treatment, while CoMag handles chemical-type clarification, with drinking water certification pending and expected soon. Both are compact systems designed to reduce footprint and save capital.

“We can come in and double the capacity of a treatment plant without building new tanks,” said Siemens’ Marc Roehl, speaking about BioMag. “And with CoMag, we can retrofit an existing clarifier and get much better capacity and performance out of the same space.”

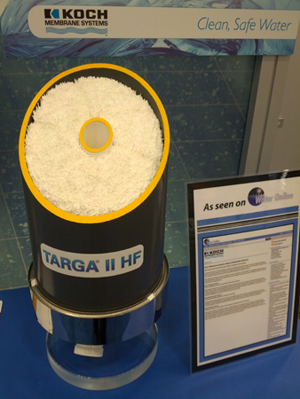

TARGA II Hollow Fiber (HF) Ultrafiltration Membrane And System

Koch Membrane Systems

Koch Membrane Systems (KMS), a company that has logged half a century in the membrane filtration business, had its latest development on display at ACE12. This year, KMS introduced the TARGA II HF, featuring a membrane design based on polyethersulfone (PES) chemistry to increase fiber tensile strength. According to the company, the module has one of the highest membrane packing densities per cartridge available in the market, with a rack that is more than 30% smaller than competitors for the same membrane area. That means not only a smaller footprint, but reduced capital costs. Also important: The TARGA II HF ensures 4-log virus removal for drinking water.

Super-pack: TARGA II HF’s membranes

DR 6000 UV-Vis Spectrophotometer

Hach Company

In response to today’s strict water-quality requirements, Hach has launched its most comprehensive spectrophotometer yet, the DR 6000, suitable for drinking water, industrial water, and wastewater. The unit can take absorbance readings of a single sample at different wavelengths or over a specific period of time, and allows high-speed wavelength scanning across the UV and visible spectrum. It comes equipped with RFID technology, integrated QA software, and more than 250 testing methods, yet is easier to use than previous models thanks to on-screen guided procedures.

The DR 6000 Spectrophotometer on display

To further simplify the lab-testing process, Hach’s Rick Sherman showed me how the DR 6000 accommodates the company’s EPA-approved TNTplus reagent vials, which are bar-coded to enable automatic method and wavelength selection. The test results can then be sent directly to WIMS (Water Information Management Solution) for integrated data analysis and plant-level optimization.

IVP 250 Insertion Valve

Hydra-Stop, a division of ADS LLC

At times on the tradeshow floor, you get the unique opportunity to see how a product is utilized in the field. In visiting with Hydra-Stop, I was treated to that experience through a hands-on demonstration of the 16-inch IVP 250 insertable gate valve by Lead Engineer Brian Ries. The valve is based on the Insta-Valve Plus, which the company purports to be the most installed gate valve in the industry. The new model improves on its predecessor’s 150 psi rating with a 250 psi working pressure and a 375 psi test pressure, but its selling point is that it allows for pipe replacement or repair without shutting down the water supply. Avoiding system shutdown means avoiding health risks and inconveniences for water customers, Ries noted, in addition to saving money and a more than a few headaches for utilities.

Brian Ries of Hyrda-Stop demonstrates the IVP 250 insertion valve.

MegaNet Fixed Network AMI Solution

Elster AMCO Water

A stop by the booth at Elster led me to Tom Gwynn, president and regional director of Elster AMCO Water, who enlightened me with a discussion on “the importance of frequency” — important to Elster because the MegaNet AMI system’s 2-watt radio transmits at 170 to 174 megahertz VHF (very high frequency) or 450 to 454 megahertz UHF (ultra high frequency). According to Gwynn, it is typical for fixed network AMIs to operate at or near 900 megahertz, unregulated, whereas Elster works on a high-powered, licensed network. That difference allows the MegaNet to transmit six times further than its low-power counterparts, capturing more meter reads with 5 to 10 times fewer collection points.

The MegaNet meter and transmitter

HF-38 Fluorimeter

HF scientific, Inc.,

Recognized as part of the ACE12 New Product Technology Showcase, the HF38 Flourimeter provides test results for heavy metals — including lead, mercury, copper, and uranium — in under a minute. The handheld instrument incorporates a DNA sensor that gives fluorescence-based readings, meaning no reagents or hazardous materials are required.

John Murray proudly represents HF scientific in the New Product Technology Showcase.

When asked what separates the HF-38 from other instruments, to earn its spot in the showcase, John Murray of HF scientific noted its ease-of-use, accuracy, and efficiency. It requires no special skills or knowledge to operate, it meets U.S. EPA standards, and, according to Murray, each test costs a fraction of the overall cost of comparable methods.

EM-mini Filtration System

Filtronics, Inc.

With decentralized water treatment on the rise, there will surely be a need for filtration systems geared toward smaller communities, schools, and commercial or industrial facilities. That’s the idea behind the new EM-mini, a pre-packaged system specificially designed for applications from 10 to 100 gpm. The EM-mini removes arsenic, iron, manganese, and other metals with Filtronics’ NSF-certified Electromedia I, which requires minimal chemical dosage and never needs replacement.

Robert Wise (left) and Steve Smee of Filtronics pose with the EM-mini.

According to Filtronics VP Steve Smee, the system is easy to use, with no operator certifications needed. Permitting is easy as well, saving time and money in the installation process. And because the EM-mini has such a small footprint, it is highly portable and can fit into small spaces. Every consideration, said Smee, was made to make the EM-mini simple and economical.

See also: