INDUSTRIAL WATER AND WASTEWATER TREATMENT

How To Remove Silica From Industrial Wastewater Efficiently

How To Remove Silica From Industrial Wastewater Efficiently

Silica can secretly wreak havoc in many industrial applications. Addressing this invisible issue can save your equipment. It will also optimize maintenance while mitigating costly downtime from scale deposit buildup.

WATER AND WASTEWATER SOLUTIONS FOR THE OIL AND GAS INDUSTRY

-

Pile Cloth Media Filtration Effectively Removes COD And TSS From Oil Refinery Wastewater

This application profile focuses on two test sites with different treatment requirements and describes how Aqua-Aerobic Systems’ OptiFiber® pile cloth media filtration was used at both sites to address the removal of harmful constituents from refinery wastewater.

-

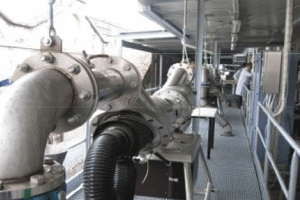

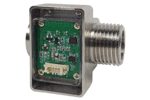

Thermal Flare Gas Flow Meter Solves Measurement Challenges On FPSO Vessels

The accurate measurement and disposal of flare gases aboard floating production storage and offloading (FPSO) vessels is essential to manage these potentially hazardous combustible, flammable and toxic gases. Accurate measurement of these waste gases allows them to be processed efficiently and effectively to protect people and equipment aboard the vessel. Measuring of flare gas is also most often a strict regulatory requirement, as it can form the basis for payment of environmental taxes, climate quotas, etc.

-

How A Biogas Processing System Manufacturer Identified The Best Flow Meter For Gas Measurement

Klargastechnik Deutschland GmbH is a leading bioengineering, designer, manufacturer and installer of biogas and disgester gas processing equipment and systems that is headquartered in Germany. The company’s products include all-welded gas storage tanks, flare systems, dry and biological desulphurization systems, explosion proof (ATEX) certified blowers, gas drying units, filters and accessories.

-

How To Manage The 4 Water-Based Fluids Associated With Hydraulic Fracturing

The primary fluid used in hydraulic fracturing is water and the completion process can require from 2.75 - 8.25 million gallons per well. This white paper discusses the different water management and instrumentation requirements for controlling and processing drilling mud, hydraulic fracturing fluid, flowback water and produced water.

-

Blowback From Flowback: Push For Groundwater Alternatives

About 50 percent of the nation’s residents source their fresh water supply from groundwater wells, which have deteriorated throughout the U.S. over the past decade. For shallow wells, severe drought conditions have gradually depleted groundwater levels.

WATER AND WASTEWATER SOLUTIONS FOR THE FOOD AND BEVERAGE INDUSTRY

-

How To Be More Industrious About Water-Quality Measurement

Precise water quality is critical for municipal water treatment operations, but many industrial applications have even more rigorous requirements, regulations, and guidelines to follow. The energy, pharmaceutical, food processing, and other industrial fields require exact water quality in order to function efficiently.

-

Alcoholic Beverage Fusel Alcohol Testing With Static Headspace

A static headspace method was developed using Teledyne Tekmar automated headspace vial samplers to meet the method requirements of the Alcohol and Tobacco Tax and Trade Bureau of the US Department of the Treasury (TTB) method SSD: TM:2001 for testing fusel alcohols in alcoholic beverages.

-

Autolyzed Excess Yeast: Control Breweries Energy Footprint

Beer brewing and processing is complex and energy intensive. And despite significant technological improvements, energy consumption remains a major environmental challenge in the brewing industry, together with wastewater and produced byproducts.

-

Conducting Accurate Conductivity Measurement In Industrial Applications

While some water quality parameters may get more attention in industrial settings, few are more critical than conductivity. Understanding conductivity monitoring for industrial applications — where it is needed, how it works, and how to leverage the appropriate instruments and standards in order to pinpoint it — will unlock huge gains in efficiency, effectiveness, and regulatory compliance.

-

Treating Food Wastewater Efficiently Using Jet Aeration

Food processing is a water-intensive process, and its wastewater byproduct is typically high in volumetric daily flow and also biochemical and chemical oxygen demand (BOD and COD), organics, and nutrients. Consequently, significant on-site treatment and resources are necessary.

WATER AND WASTEWATER SOLUTIONS FOR THE POWER GENERATION INDUSTRY

-

Why Strategic Choices — And Water — Could Make People More Energy-Efficient

At my household, a new year means a new energy and water-use baseline. By that I mean, every month, I look at how much electricity and water I used in comparison to the same month the previous year — so I can try to be as efficient as possible. But I work in the energy field, and I know that’s not a typical New Year’s tradition. Most people don’t examine the trends of their energy-use or spend much time thinking about how to reduce it.

-

Thermal Flare Gas Flow Meter Solves Measurement Challenges On FPSO Vessels

The accurate measurement and disposal of flare gases aboard floating production storage and offloading (FPSO) vessels is essential to manage these potentially hazardous combustible, flammable and toxic gases. Accurate measurement of these waste gases allows them to be processed efficiently and effectively to protect people and equipment aboard the vessel. Measuring of flare gas is also most often a strict regulatory requirement, as it can form the basis for payment of environmental taxes, climate quotas, etc.

-

Hydro Schemes Have An Impact In Scotland

At the end of 2011, the total hydroelectric installed capacity in the United Kingdom accounted for approximately 1.67 Gigawatts (GW) of installed electrical generating capacity, being 1.9% of the current total UK generating capacity, and 14% of the UK's renewable energy generating capacity.

-

Design-Build Using Actiflo Technology

A state-of-the-art 695-MW power generation facility was recently installed in the Northeastern U.S. to serve the country’s highest demand market. Its innovative power generation technologies, emissions control systems and process efficiencies make it one of the cleanest, most efficient and technologically advanced supercritical pulverized coal (SPC) power plants in the U.S.

-

ABB Ability: Our Offering For Power Plants

ABB provides an extensive selection of proven measurement and analytical products and solutions for power generation industry applications.

WATER AND WASTEWATER SOLUTIONS FOR INDUSTRY

-

Why Strategic Choices — And Water — Could Make People More Energy-Efficient

At my household, a new year means a new energy and water-use baseline. By that I mean, every month, I look at how much electricity and water I used in comparison to the same month the previous year — so I can try to be as efficient as possible. But I work in the energy field, and I know that’s not a typical New Year’s tradition. Most people don’t examine the trends of their energy-use or spend much time thinking about how to reduce it.

-

Q-SEP Ultrafiltration Reduces Water Footprint And Recycles Wastewater For Textile Mill

An existing effluent treatment plant was not meeting the a textile mill’s requirements for the recycle and reuse of textile effluent water for process purposes. QUA supplied Q-SEP 6008 ultrafiltration modules as part of a water treatment system that includes equalization, flash mixing, flocculation, clarifier, rapid sand filter, holding tank, MGF, ACF, Q-SEP ultrafiltration, and reverse osmosis. Read the full project profile to learn more.

-

CCD Technology Succeeds With Well Water Purification

The Kittansett Golf Club in Marion, Massachusetts is rated one of America’s 100 Greatest Golf Courses by Golf Digest Magazine.

-

How To Design A Better Carbon-Filtration Solution

Here is a look at how synthetic carbon technology makes it easier to design a better filtration medium tailored to the most challenging process demands.

-

Thinking About Medicines And Personal Care Products In Drinking Water

Examples of medicines and personal care products detected in water include antimicrobial materials found in toothpastes and hand soaps, fragrances, prescription medicines, bug sprays, and sunscreen. Concentrations of these substances detected in water are typically very small and are currently not regulated at the federal level in the U.S.

-

How To Minimize Downtime In Ultrapure Water Systems

As ultrapure water becomes increasingly indispensable, new technologies redefine industrial standards, fostering resilience and competitiveness in a rapidly evolving global market.

-

Pile Cloth Media Filtration Effectively Removes COD And TSS From Oil Refinery Wastewater

This application profile focuses on two test sites with different treatment requirements and describes how Aqua-Aerobic Systems’ OptiFiber® pile cloth media filtration was used at both sites to address the removal of harmful constituents from refinery wastewater.

-

TSCA Modernization: A Dose Of Common Sense

After 40 years, the 1976 Toxic Substances Control Act (TSCA) has finally been updated, much to the delight of most — but certainly not all.

-

How To Be More Industrious About Water-Quality Measurement

Precise water quality is critical for municipal water treatment operations, but many industrial applications have even more rigorous requirements, regulations, and guidelines to follow. The energy, pharmaceutical, food processing, and other industrial fields require exact water quality in order to function efficiently.

-

Thermal Flare Gas Flow Meter Solves Measurement Challenges On FPSO Vessels

The accurate measurement and disposal of flare gases aboard floating production storage and offloading (FPSO) vessels is essential to manage these potentially hazardous combustible, flammable and toxic gases. Accurate measurement of these waste gases allows them to be processed efficiently and effectively to protect people and equipment aboard the vessel. Measuring of flare gas is also most often a strict regulatory requirement, as it can form the basis for payment of environmental taxes, climate quotas, etc.