DRINKING WATER

Pitot Testing: The Gold Standard For Wholesale And Production Meter Accuracy Evaluation

Pitot Testing: The Gold Standard For Wholesale And Production Meter Accuracy Evaluation

For most water utilities, master and production meters represent the system's financial and operational truth. These meters quantify the volume of water entering the distribution network, support water accountability programs, validate NRW calculations, and influence everything from treatment costs to rate structures.

DRINKING WATER CASE STUDIES AND WHITE PAPERS

-

Triple Threat Creates A Tough Challenge For Pennsylvania Water Authority

A well-known university, a busy main street, a 100-year-old pipeline and a tight deadline made for a tough challenge for crews attempting to install a 12-inch AMERICAN Fastite pipe in State College, Pennsylvania, this past summer.

-

Factoring Temperature Into Water Chemistry Reading Accuracy

In water testing, readings that we believe to be reliable indicators are not always what they seem. Water that exhibits certain chemical or electrical characteristics at laboratory temperatures can provide entirely different readings in the field. Here is a quick review of what to look for in common water tests and why to consider automatic temperature compensation in the instruments used to collect them.

-

How To Conduct Water Quality Analysis For Ozone Disinfection

Because ozone is relied on so heavily to oxidize a wide variety of potential wastewater contaminants, water quality analysis during the disinfection process is paramount. Once the ozone process itself is understood, its water quality ramifications and the quality parameters that offer insight into its efficacy can be analyzed and taken into account.

-

Color Reduction From RO Concentrate

The City of Palm Coast, FL was experiencing elevated color in the concentrate stream being directed to the lime softening facility to recover as drinking water. In an effort to meet secondary color standards at the lime plant, this water quality issue limited the volume of the concentrate able to be recovered.

-

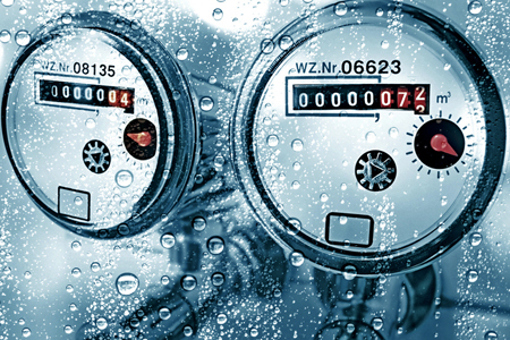

Accurate Metering For Every Water Consumer's Habits

Utilities looking for greater billing efficiency and control over every drop of water consumed by their customers face a constant battle with non-revenue water loss, which can be compounded by different metering technologies and consumer behaviors. Using accurate, always-on, continuous-sampling meters to take full advantage of automated smart utility networks is a better way to improve decision-making and achieve accountability goals across any circumstances.

-

Connecticut Water Utility Successfully Removes 45% Of Trihalomethanes (THMs)

While the addition of chlorine is one of the safest and most effective means for water disinfection, under certain circumstances chlorine in combination with naturally occurring organic compounds in water can lead to the formation of undesirable disinfection byproducts (DBPs).

-

How Targeted Investments By Private Water Can Boost Public Support

A significant number of utilities operating in smaller regions where resources are strained, and where the daily business of water treatment can be exceedingly expensive, have turned to privately owned companies to manage their drinking water and wastewater operations. The downside is that this arrangement also tends to bring heavy scrutiny from a public that expects the provider to put service above the bottom line. Fortunately, targeted investments in solutions can address the issue.

-

How Changing Weather Patterns Impact Water Main Leaks And Breaks

This blog aims to provide utility managers, policymakers, and the public with a detailed understanding of the current state of water main infrastructure and the environmental challenges faced in maintaining these systems.

-

From Challenge & Prize Competition To Test Prototype: The Nitrogen Sensor That Could Change Residential Onsite Wastewater Treatment

More than one in five households in the United States depend on septic or onsite systems to treat their wastewater. These systems provide critical water quality infrastructure, but they usually are not designed to remove nitrogen to the point that sufficiently protects coastal marine ecosystems. As a result, septic systems are known to contribute to eutrophication (excess nutrients), hypoxia (low levels of oxygen), and harmful algal blooms in marine and estuarine waters.

-

BEACON SaaS Helps Eliminate Human Error And Reducing Time Spent In The Field

Servicing more than 3,000 residents in the Greenfield Village and Copper Creek subdivisions in northwest Houston, Texas, Harris County Utility District (UD 15) had an aging water metering system with numerous inefficiencies. As a result, the district was experiencing lost revenues and inaccurate meter readings. It was time to replace the system.

DRINKING WATER APPLICATION NOTES

-

Analyzing Total Organic Carbon In Sea Water4/2/2015

The analysis of Total Organic Carbon (TOC) in seawater can be both challenging and expensive. The concentration of organic carbon in seawater is of considerable interest. The effect this matrix can have on TOC analyzers can lead to rapid consumable turnover, costly maintenance and repairs.

-

Performance Test Services For UV Advanced Oxidation Systems12/1/2025

UV AOP performance verification requires a robust test matrix covering design, operating, and control conditions. This process includes on-site execution, sample analysis, and troubleshooting to achieve successful regulatory approval.

-

Determination Of Pesticide Residues In Tea4/10/2015

In 2012, Americans consumed well over 79 billion servings of tea, which is just over 3.60 billion gallons.

-

Take Control Of Your Water Distribution Network With Digitalization And Remote Monitoring5/19/2022

Any process plant constantly generates a high volume of status data. Today, this data can be extracted from the plant, stored, analyzed, and prepared to meet operator needs and lower marginal costs.

-

Panametrics Technology Helps Track Potable Water Leaks4/22/2022

Concerned about the volume of water leakages throughout their network, a Swedish water authority turned to Panametrics flowmeters to map their municipal water network -- enabling quick leak identification and fixes.

-

Application Note: Low-Flow Sampling Of Water Quality Parameters Used In Determining Groundwater Stability1/20/2010In April 1996, the U.S. EPA developed and published a document entitled Low-Flow (Minimal Drawdown) Ground-Water Sampling Procedures. The document states that “the most common ground water purging and sampling methodology is to purge wells using bailers or high speed pumps to remove 3 to 5 casing volumes followed by sample collection.” Adverse impacts can occur through this method affecting sample quality by increasing levels of turbidity. These problems can often be mitigated by using low-flow purging and sampling to reduce sampling-induced turbidity. By YSI

-

Application Note: YSI Water Quality Monitoring Buoys Help Connecticut DOT Protect The Housatonic River12/27/2005When replacement of the Sikorski Bridge spanning the Housatonic River was authorized, Paul Corrente and the Connecticut Department of Transportation (CT-DOT) set about the design and development of a water quality monitoring program to monitor the contractor’s in-water activities to insure full protection of the river from perturbation

-

Industry-Specific Applications For UV Technology6/17/2024

In Microelectronics, Aquafine UV systems provide a synergistic approach towards the reduction of trace organics and microbial contamination for ultrapure water.

-

Simplify And Optimize Your Process With Level And Pump Control3/1/2022

Level controllers have evolved to meet today’s environmental challenges and industry demands. Learn how they support improved process management and, ultimately, a better bottom line.

-

Secret To Disinfection Monitoring For High Chlorine Residual Wastewater Applications8/2/2015

Some wastewater applications require chlorine residuals greater than can be effectively monitored using DPD due to the oxidation of the Wurster dye to a colorless Imine. Such applications include industrial wastewater processes that inherently have a high chlorine demand thereby requiring a more robust monitoring method.

LATEST INSIGHTS ON DRINKING WATER

-

Around the world, rivers are no longer changing gradually. Rather, they are being increasingly transformed by extreme climatic events such as floods, droughts, and heatwaves. A newly published global review finds these events are pushing ecosystems beyond their limits and eroding biodiversity and core functions.

-

The U.S. EPA is testing a new procedural strategy to remove four PFAS drinking‑water limits from ongoing litigation, asking the D.C. Circuit Court of Appeals to invalidate those limits on the grounds that the EPA itself committed a procedural misstep when issuing the 2024 PFAS rule.

-

A recent study argues that the traditional, manual approach to drinking-water distribution-network monitoring and leak prevention is no longer sustainable. Instead, utilities must embrace the Internet of Things (IoT) to transition from reactive repairs to proactive asset management.

-

With the rise of water scarcity, environmental regulations, and corporate sustainability mandates, produced water treatment has become a strategic imperative for industries far beyond oil and gas. It is one of the fastest-growing segments in the water treatment industry, which has emerged as an amalgamation of environmental stewardship, regulatory compliance, and technological innovation.

-

In the U.S. alone, 2.7 trillion gallons of water are lost to non-revenue water (NRW) every year, costing water utilities more than $6.4 billion annually in unrealized revenue. Given the scale of the issue — volumes and dollars — NRW presents an opportunity for upscaling utility management.

-

Despite renewed public concern over fluoride and cognition, the National Toxicology Program’s findings focus on high‑fluoride groundwater conditions — not the controlled levels used in U.S. drinking water systems. Understanding that distinction is critical for utilities navigating policy questions and community expectations.

ABOUT DRINKING WATER

In most developed countries, drinking water is regulated to ensure that it meets drinking water quality standards. In the U.S., the Environmental Protection Agency (EPA) administers these standards under the Safe Drinking Water Act (SDWA).

Drinking water considerations can be divided into three core areas of concern:

- Source water for a community’s drinking water supply

- Drinking water treatment of source water

- Distribution of treated drinking water to consumers

Drinking Water Sources

Source water access is imperative to human survival. Sources may include groundwater from aquifers, surface water from rivers and streams and seawater through a desalination process. Direct or indirect water reuse is also growing in popularity in communities with limited access to sources of traditional surface or groundwater.

Source water scarcity is a growing concern as populations grow and move to warmer, less aqueous climates; climatic changes take place and industrial and agricultural processes compete with the public’s need for water. The scarcity of water supply and water conservation are major focuses of the American Water Works Association.

Drinking Water Treatment

Drinking Water Treatment involves the removal of pathogens and other contaminants from source water in order to make it safe for humans to consume. Treatment of public drinking water is mandated by the Environmental Protection Agency (EPA) in the U.S. Common examples of contaminants that need to be treated and removed from water before it is considered potable are microorganisms, disinfectants, disinfection byproducts, inorganic chemicals, organic chemicals and radionuclides.

There are a variety of technologies and processes that can be used for contaminant removal and the removal of pathogens to decontaminate or treat water in a drinking water treatment plant before the clean water is pumped into the water distribution system for consumption.

The first stage in treating drinking water is often called pretreatment and involves screens to remove large debris and objects from the water supply. Aeration can also be used in the pretreatment phase. By mixing air and water, unwanted gases and minerals are removed and the water improves in color, taste and odor.

The second stage in the drinking water treatment process involves coagulation and flocculation. A coagulating agent is added to the water which causes suspended particles to stick together into clumps of material called floc. In sedimentation basins, the heavier floc separates from the water supply and sinks to form sludge, allowing the less turbid water to continue through the process.

During the filtration stage, smaller particles not removed by flocculation are removed from the treated water by running the water through a series of filters. Filter media can include sand, granulated carbon or manufactured membranes. Filtration using reverse osmosis membranes is a critical component of removing salt particles where desalination is being used to treat brackish water or seawater into drinking water.

Following filtration, the water is disinfected to kill or disable any microbes or viruses that could make the consumer sick. The most traditional disinfection method for treating drinking water uses chlorine or chloramines. However, new drinking water disinfection methods are constantly coming to market. Two disinfection methods that have been gaining traction use ozone and ultra-violet (UV) light to disinfect the water supply.

Drinking Water Distribution

Drinking water distribution involves the management of flow of the treated water to the consumer. By some estimates, up to 30% of treated water fails to reach the consumer. This water, often called non-revenue water, escapes from the distribution system through leaks in pipelines and joints, and in extreme cases through water main breaks.

A public water authority manages drinking water distribution through a network of pipes, pumps and valves and monitors that flow using flow, level and pressure measurement sensors and equipment.

Water meters and metering systems such as automatic meter reading (AMR) and advanced metering infrastructure (AMI) allows a water utility to assess a consumer’s water use and charge them for the correct amount of water they have consumed.