Zero Liquid Discharge Project Turns Treatment Byproduct Into Drinking Water

By Phillip Locke, Fred Greiner, and Ryan Popko

What’s the most sustainable way of dealing with reverse osmosis and nanofiltration membrane concentrate, particularly in water-scarce Florida? Treat it and drink it.

Using unconventional sources often requires the implementation of new process applications to meet potable water treatment requirements and demands. Effectively treating waste streams can be an essential part of meeting alternative water supply goals. Although membrane treatments — specifically reverse osmosis (RO) and nanofiltration — feature significant benefits in treating water to a consistently high level, managing the treatment process byproduct, or concentrate, can be a challenge.

Meeting The Challenge

The City of Palm Coast, FL, had explored several methods to develop alternative water supplies, recover and reuse water, and reduce the utility’s environmental impact. The city’s consumptive use permit limited source water supplies, while regulatory constraints required an alternative means of concentrate disposal. Because of these constraints, the city elected to treat and recover its RO concentrate as an alternative water supply, using a unique zero liquid discharge (ZLD) process at the water treatment plant (WTP) No. 2 membrane softening facility.

The ZLD process is capable of treating 1.2 MGD of low-pressure RO concentrate using lime and soda ash softening, membrane filtration, and disinfection. It allows the city to treat and recover nearly 100 percent of the WTP-produced concentrate that was previously discharged to a surface water body. The process treats the concentrate stream to a level that complies with all primary and secondary drinking water standards when blended with the plant’s finished water and increases the facility’s capacity by 1.2 MGD without additional source water supplies.

An aerial view of WTP No. 2 shows many of the facilities built to treat and recover the plant’s RO concentrate as an alternative water supply using the ZLD process, including (clockwise from top left) a sludge dewatering facility, a lime silo, a posttreatment and ultrafiltration building, and solids contact clarifiers.

Palm Coast’s ZLD project evolved after the city’s most recent National Pollutant Discharge Elimination System concentrate discharge permit renewal, as the U.S. EPA and Florida Department of Environmental Protection determined that the use of an extended mixing zone for water quality compliance was no longer feasible. The city evaluated 12 alternative disposal methods of concentrate based on treatability, feasibility, and economics. After bench-scale and pilot testing, the city selected ZLD for its WTP No. 2. The concentrate ZLD option provided concentrate recovery as an alternative water supply for potable use and for beneficial reuse of solids removed from the concentrate stream. The local water management district’s push for the use of alternative water supplies was also a factor in ZLD selection.

An aerial view of WTP No. 2 shows many of the facilities built to treat and recover the plant’s RO concentrate as an alternative water supply using the ZLD process, including (clockwise from top left) a sludge dewatering facility, a lime silo, a post-treatment and ultrafiltration building, and solids contact clarifiers.

Process Design

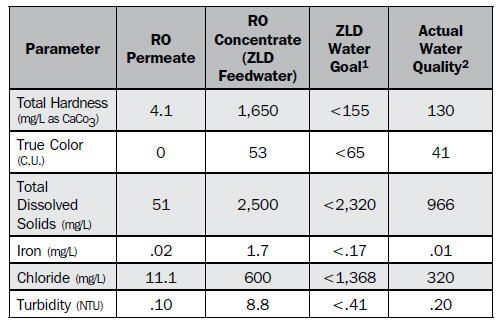

The primary components of the ZLD process include lime and soda ash softening, clarification, ultrafiltration (UF) feed system, pressurized UF membrane system, UF backwash and cleaning system, disinfection system, process recycle and recovery system, solids handling system, sludge dewatering system, process and yard piping, electrical systems, and instrumentation and control systems. The table below presents the water quality parameters used to design the concentrate ZLD system.

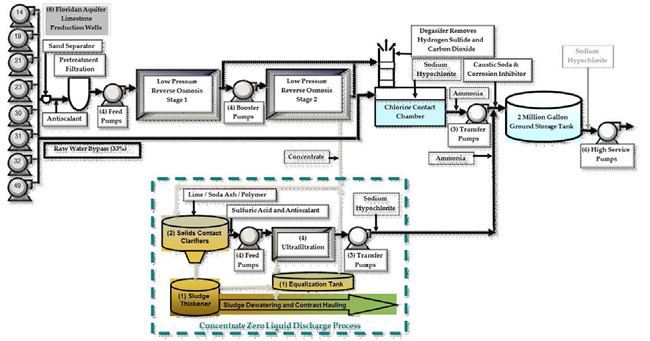

As detailed in the process flow diagram below, the concentrate ZLD process consists of softening by chemical precipitation followed by UF primarily to reduce carbonate and noncarbonate hardness, as well as some total organic carbon and color. Lime and soda ash are used to precipitate carbonate and noncarbonate hardness in two solids contact clarifiers, and a polymer is added to enhance settling. The pH of the softened water is adjusted and a scale inhibitor is added before water is transferred to the UF feed tank. The UF feed pumps transfer the softened water through automatic backwash strainers and a pressurized vertical UF system that removes the remaining suspended solids. The UF system was designed to provide 100 percent treatment capacity when one of the plant’s four trains is offline for cleaning, maintenance, or repair. The UF elements are cleaned through permeate backwash, chemically enhanced backwash, and clean-in-place (CIP) operations.

The chemically enhanced backwash uses sulfuric acid, sodium hydroxide, or sodium hypochlorite. CIP operations use citric acid, sodium hydroxide, or sodium hypochlorite. The UF system is housed in a pre-engineered metal building designed to accommodate additional UF membranes and other components to allow for a future expansion of the ZLD process to 1.8 MGD. After the softened water is filtered by the UF membranes, the UF filtrate is conveyed to the UF filtrate and backwash tanks. The filtrate from the UF filtrate and backwash tanks is disinfected using free chlorine before blending with the combined permeate and raw water bypass water directly upstream of the existing ground storage tank and converting to chloramines for final disinfection.

In addition to the main ZLD process stream, two other process streams are associated with the concentrate ZLD process: a solids stream and a recycle stream. The system recovers over 99.3 percent of the concentrate. This occurs by collecting the five recycle/recovery streams and combining them in the equalization tank where they are recycled to the head of the ZLD process. The recycle streams include solids-laden softened water from the UF feed tank, UF pretreatment strainer backwash, UF-neutralized chemically enhanced backwash water, gravity sludge thickener supernatant, and belt filter press filtrate. The recovery and recirculation of the various streams within the concentrate ZLD process are imperative for successful implementation. The ZLD system was designed to produce lime sludge with approximately 50 percent dry solids.

Sludge removed from the solids contact clarifiers is transferred to a gravity sludge thickener. From there, solids removed from the gravity sludge thickener are pumped to the solids handling and dewatering system via rotary lobe pumps. Sludge is dewatered with two belt filter presses, which allows 100 percent redundancy. The dewatered solids are hauled from WTP No. 2 by the city’s contract hauler, where they are mixed with recycled concrete for dust control and act as a binder in the production of a paver base.

Project Challenges

Recycle Streams. One of the project’s biggest challenges was handling all the recycle streams needed to achieve 99.3 percent recovery. Because of each stream’s varying volume, duration, and frequency, an equalization tank with a capacity of approximately 80,000 gallons was designed and sized to provide ample capacity for the flows. In addition to providing the requisite storage for the recycle flows, the equalization tank was also fitted with a mixing system that includes jet-type mixing eductors and a pumping system to keep solids suspended in the tank.

Three recycle pumps for the equalization tank transfer the various recycle flows back to the head of the ZLD process, directly upstream of the solids contact clarifiers, where the flows are mixed with the influent concentrate. Even with the equalization tank’s fairly large capacity, flow control of the recycle stream is required to avoid surges and upsets to the ZLD treatment process. As a result of the recycle flows, the process units are designed to treat flows higher than the 1.2 MGD concentrate flow to accommodate the recycle streams. For 1.2 MGD concentrate, the treatment process is designed to handle an additional 0.65 MGD of recycle flow.

The equalization tank was installed below grade to allow for gravity flows to it, so self-priming (rather than submersible) pumps were selected, in large part because of the potentially corrosive equalization tank water. Submersible pumps would need to be constructed entirely of stainless steel to withstand the environment, which wasn’t economically feasible. Flow control evaluations considered variable frequency drives (VFDs), motorized V-port discharge ball valves, and multiple pumps. VFDs were eliminated from consideration because of concerns about keeping the pumps primed at low motor speeds. Three pumps, along with a flow-controlled V-port ball valve on the common recycle line, were selected for the implementation.

Disinfection. Another significant challenge for the project was how to disinfect the ZLD-treated water without exceeding disinfection byproduct (DBP) limitations. The city was providing 4-log virus treatment in accordance with the Ground Water Rule through free chlorine addition to the blended permeate and raw water bypass in the clearwell prior to chloramination. The project’s original concept was to combine the ZLD-treated water with the permeate and the raw water bypass streams in the clearwell, but higher TOC concentrations in the ZLD-treated water were a concern. Because the lime and soda ash softening combined with membrane filtration can provide 2-log virus inactivation, the ZLD-treated water was disinfected separately with free chlorine to provide the remaining 2-log virus treatment before chloramination.

Integrating With An Existing Facility

The concentrate ZLD process is complex and needed to be fully integrated with its respective components as well as the existing plant so the facility could operate as a single entity. This operational approach complies with the operating permit that was issued to incorporate the concentrate ZLD process and increase the plant’s overall capacity.

The instrumentation and SCADA system associated with the ZLD process was integrated into WTP No. 2’s existing SCADA system

Operational Considerations

Instrumentation And Electrical. The existing instrumentation and SCADA system at WTP No. 2 consisted of a centralized plant control system providing monitoring and operating capability from a centralized computer system. Plant operations were directly wired into the control room’s programmable logic control cabinet, and the system was expanded to incorporate and completely integrate all the ZLD processes into the modified SCADA system. These changes allow operators to monitor and control all the plant’s operations and processes from a single location.

Electrical And Standby Power. The electrical system for the existing facility was expanded and upgraded to accommodate the ZLD process. The existing emergency generator was rehabilitated and used for the concentrate ZLD process. A new emergency generator was installed to reinforce the plant’s reliability. This approach was more cost-effective than replacing the existing emergency power system with a larger system to safeguard the expanded operations. The electrical system’s design, including sequencing its two generators, minimized the need for plant shutdowns during construction.

Yard Piping And Underground Utilities. The existing raw water bypass piping was relocated to accommodate the new UF building. A significant amount of piping and other underground utilities exist onsite. As a result, new piping and other underground utilities placement was challenging, which is a common issue when improving an existing facility. The keys to success were identifying existing piping and utilities early in the project through the use of record drawings, subsurface utilities excavations, and staff ’s knowledge of previous plant improvements.

Current Status

Substantial completion of the concentrate ZLD project occurred on March 2, 2015. The team experienced a few challenges during startup, but these were overcome by close collaboration with the City of Palm Coast, the engineer of record (McKim & Creed, Inc.), the contractor (Wharton-Smith), and the original equipment manufacturer (Doosan Hydro Technology). Additionally, operational modifications are being tested and implemented to reduce DBP formation. In April, the team was awarded the David W. York Water Reuse Project of the Year award by the Florida Water Environment Association.

About The Authors

Phillip Locke, PE, is a senior project manager with McKim & Creed, Inc. and served as project manager and lead process engineer of Palm Coast’s ZLD project. He has more than 20 years of experience, including serving as engineer of record for five advanced water treatment projects.

Phillip Locke, PE, is a senior project manager with McKim & Creed, Inc. and served as project manager and lead process engineer of Palm Coast’s ZLD project. He has more than 20 years of experience, including serving as engineer of record for five advanced water treatment projects.

Fred Greiner is the chief operator of WTP No. 2 for the City of Palm Coast.

Ryan Popko, PE, served as project engineer on the ZLD project while with McKim & Creed. Currently, Ryan is a process engineer with JEA.