Wastewater Laboratory Selection And Sampling Best Practices

By Brenda Martinez

Sending samples out still requires a level of responsibility and competency. Follow these steps to ensure accurate water quality analysis.

In an industry that relies on sound and accurate data for design and maintenance of onsite wastewater treatment systems, it is important to understand the proper procedures for laboratory selection and sample collection when doing analytical testing. The main constituents tested in the wastewater treatment industry are biochemical oxygen demand (BOD), carbonaceous biochemical oxygen demand (cBOD), total suspended solids (TSS), chemical oxygen demand (COD), fecal coliform, and different suites of nutrient analysis, including nitrogen and phosphorus. These are the common parameters that define effluent water quality, and that are typically used as permit parameters through the National Pollution Discharge and Elimination System (NPDES). Before beginning the process of sample collection, influent and effluent parameters important to the site must be understood. That information is available from the site-issued NPDES permit or the regulating body. The common parameters above are also a good place to start.

Laboratory Selection

There are several labs in the U.S. that will run water quality analyses. However, it is important to select a laboratory that holds NELAC and/or ISO 17025 accreditations, since these facilities will provide methods and reporting formats that are in line with permit reporting requirements. National Environmental Laboratory Accreditation Program (NELAP) accredited laboratories undergo strict and periodic third-party evaluations for method compliance, quality assurance, sample integrity, and other criteria, and must pass annual audit inspections to maintain their accreditations. The same applies to laboratories certified under the International Standards Organization (ISO). Look for the NELAP stamp on the lab website, or, if unsure, contact the lab and confirm certification prior to contracting their services.

Labs use a variety of different-sized bottles, with different shapes, to satisfy test method requirements. Each bottle serves an important purpose in the lab.

Test Methodologies

It is important to understand the difference between accredited laboratory tests and onsite field tests, which are not typically recognized for permit reporting. Operators should have a small onsite laboratory where parameters such as pH, dissolved oxygen, and settleability can be measured. Some even have kits for onsite testing of nutrients and COD. There is, however, a difference between onsite test kits and laboratory equipment. Onsite data cannot be used for reporting purposes because an onsite lab does not have any validation. In other words, there is no one reviewing the data for accuracy and completion or inspecting the equipment periodically for proper maintenance and calibration. Also, onsite methods have no quality checks on data validation and the instruments used in laboratories are much more efficient, allowing for more accurate and reliable test results. That said, onsite test kits are still very important and highly recommended because they enhance operational awareness regarding the day-by-day general health and performance of the system.

"It is important to understand the difference between accredited laboratory tests and onsite field tests, which are not typically recognized for permit reporting."

If the site is being monitored for effluent quality by a regulating body, there are certain test methods that are acceptable for reporting purposes. These test methods are published and validated by accrediting bodies and include the EPA Standard Methods for the Examination of Water and Wastewater (SM), American Society for Testing and Materials (ASTM), and ISO. Simply stating “BOD” or “COD” may not be enough information. If the laboratory is aware that samples are being submitted for wastewater quality testing, they may automatically plug the appropriate test methods into their system. Make it a practice to know what is required for your site and never assume that the correct methods will be provided. For example, BOD should be analyzed by SM5210B. That is the current EPA-approved method of analysis. However, Standard Methods describes four test procedures for assessing BOD, and the laboratory may be capable of all four. It is important that SM5210B is requested, to comply with the standard, should the data need to be reported.

Proper sample collection for testing requires the use of PPE, careful handling of bottles, and keeping the sample cool on the way to the lab.

Sample Kits

Once an accredited laboratory is identified and the list of test methods assembled, the next step is to request a sample bottle kit or sample collection kit from the laboratory. Even if you have your own test and/or collection bottles on hand, it is recommended that one be requested from the laboratory within two weeks of the anticipated collection date. Typically, these kits are included as part of the analysis cost, so there is no additional fee. The laboratory will need to know what matrix you are collecting (water, in this case), what test methods you need analyzed (BOD, fecal coliform, TSS, etc.), and how many samples you anticipate collecting. They will then customize a bottle kit for the project and either ship it to your requested location, deliver it, or allow you to pick it up if the facility is local. The sample kits will vary, depending on the lab, but will typically consist of: ice chest(s), various containers (types, sizes, and quantity will depend on the suite of analysis requested), sample bottle labels, and chain-of-custody paperwork. It is important to obtain the kit as close to your anticipated collection date as possible, given that chemical preservatives may be present in the containers and those preservatives do have expiration dates. The quality of results needed may not be obtained if expired chemicals are used in sample collection.

Each bottle in the kit serves a purpose and must be treated with care. Wear the proper personal protective equipment (PPE) when handling the kit, especially since some bottles may contain traces of acidic or basic chemicals. Don’t be alarmed if there is a small swirl of liquid inside the bottle. This is normal and purposely added by the laboratory staff to act as a chemical preservative. These preservatives are dictated by the test method and help ensure accurate results. Open the kit upon receipt and ensure that there is a bottle for each analysis requested. The paperwork contained and/ or bottle labels should help to identify the kit contents. If you do not see a bottle for a requested analysis, clarify with the lab before you proceed. Do not assume multiple tests can be analyzed from the same bottle. Each bottle is provided based on specific method requirements for sizing, materials, and chemical preservatives.

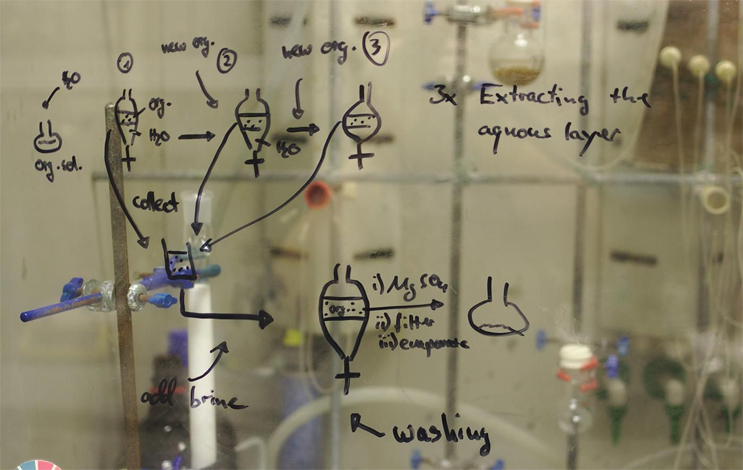

The extraction process for an analytical method

The final important piece of the sample bottle kit is the Chain of Custody (CoC) form. The CoC form must accompany samples when they return to the lab to ensure traceability. The Chain of Custody requires sample identification to be provided (the name that is given to that sample), the date of collection, time of collection, name/initials of the person who collected the sample, whether it was a grab or composite sample, and a list of analyses to be performed on that sample. The Chain of Custody is a legally binding document that demonstrates proof of ownership of those samples from the time of collection to the time the sample is received by the lab. Receiving a valid CoC with each sample submission is a requirement of every accredited laboratory.

Sample Collection

Once again, PPE is a necessity. Do not touch the inside of the containers and do not leave them exposed to the environment with the lids open. This will help prevent contamination. The laboratory should provide bottle-fill instructions with the kit as well. If this is unclear, the general rule of thumb is to fill to just above the shoulder of the bottle. In the case of bottles with preservatives, don’t overfill the bottle and risk washing out these important chemicals. Conversely, under-filling the sample bottles risks that the lab will not have sufficient volume to run the test per the requested method.

Once samples are filled, carefully cap and clearly label the container using waterproof ink. Then, place the sample bottle into a cooler, ensuring there is sufficient space left for ice. Once all bottles are filled, add ice and confirm that all bottles are sufficiently covered and all containers are well-sealed. It is important that samples are cold when they arrive at the lab. Most testing methods require a temperature of between 2-6°C inside the cooler when it is received. If the temperature is higher, it is considered an exceedance and results could be rejected by the regulating body. Once the cooler is loaded with the samples, add your paperwork, properly seal it, and immediately get the samples delivered to the lab. Be mindful of the hold times stipulated by each individual test method. These will vary based on the analysis to be completed.

Summary

It is critical to understand testing requirements and ensure that the chosen lab has the proper accreditations and the capability to analyze for the approved methods. Obtaining a sample kit from the lab in lieu of using your own bottles ensures that the correct bottles, volumes, and preservatives will be utilized. Wearing PPE when handling sample containers and collecting samples prevents personal exposure and sample contamination. Accurate paperwork and prompt delivery to the testing lab will ensure adherence to analysis method hold times. If these best practices are followed, good quality data will result, eliminating the potential headaches associated with invalid results or regulatory rejection.

About The Author

Brenda Martinez has been the commercial project manager for Delta Treatment Systems (formerly Delta Environmental) for five years. Martinez assists developers and engineers in designing wastewater treatment systems that will optimize treatment performance for their projects. Prior to working for Delta, she spent 15 years in the environmental testing industry, doing bench-scale treatability studies for municipal wastewater plants as well as standard analytical testing for soils and waters under both Standard Methods and ASTM methodologies. Martinez holds a bachelor’s degree in evironmental science from Texas A&M University, a master’s degree in environmental management from the University of Maryland University College, and is currently a Ph.D. student at Louisiana State University in the environmental science program.

Brenda Martinez has been the commercial project manager for Delta Treatment Systems (formerly Delta Environmental) for five years. Martinez assists developers and engineers in designing wastewater treatment systems that will optimize treatment performance for their projects. Prior to working for Delta, she spent 15 years in the environmental testing industry, doing bench-scale treatability studies for municipal wastewater plants as well as standard analytical testing for soils and waters under both Standard Methods and ASTM methodologies. Martinez holds a bachelor’s degree in evironmental science from Texas A&M University, a master’s degree in environmental management from the University of Maryland University College, and is currently a Ph.D. student at Louisiana State University in the environmental science program.