Waste Heat Recovery For Desalination From Steam Power Plants

By Klaas Visser, Refrigeration Engineer, KAV Consultants Pty Ltd.

Currently, in the Kingdom of Saudi Arabia (KSA), about 1.5 million barrels of oil are consumed daily to generate electricity to drive reverse osmosis (RO) desalination plants (1). This represents about 15 percent of KSA’s daily oil production. In a global context it represents about 1.8 percent of the total daily global oil production of 84.82 million barrels, the International Energy Agency’s (IEA) 2013 estimate.

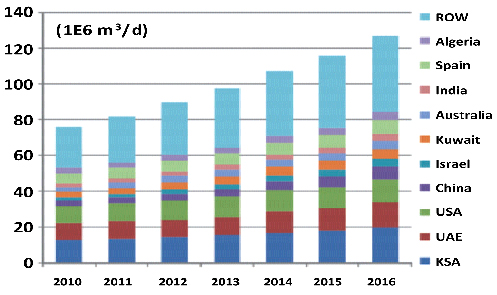

Referring to Figure 1, it is clear that other Middle East and North African (MENA) countries such as the United Arab Emirates (UAE), Kuwait and Algeria produce nearly as much desalinated water as the KSA. This means that about 3.5 percent of the total daily oil production is used to desalinate water. This is set to escalate in the short term, but it is ultimately unsustainable. This is recognized and shown in Figure 2.

Figure 1: Global installed desalination capacity, 2010 – 2016 (Pike Research, 2010)

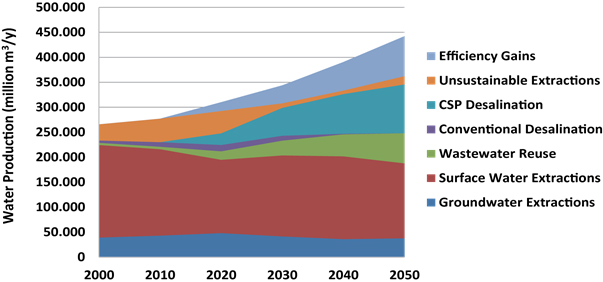

Figure 2: Water demand scenario in MENA, 2000-2050 (Source: Trieb et al, 2011)

Desalination Processes And Their Energy Inputs

In Table 1 electrical energy and heat inputs are listed for the three major desalination technologies currently employed.

Table 1. Key, typical energy data for desalination technologies (Main source: EU, 2008)

|

Parameter |

Desalination Method |

||

|

MSF |

MED |

RO |

|

|

Operation temp., °C |

90 – 110 |

70 |

Ambient |

|

Electricity demand, kWh/m3 |

2.5 – 3.5 |

1.5 – 2.5 |

3.5 – 5.5 |

|

Thermal energy demand, kWh/m3 |

80.6 (290 kJ/kg) |

80.6 (290 kJ/kg) |

0 |

In the reverse osmosis (RO) desalination process it takes an average of 4.5 kWh to produce 1,000 litres of water, i.e. the water production amounts to 222.2 litres/kWh.

Multi-stage flash (MSF) desalination requires about 3 kWh of electrical energy plus 80.6 kWh of heat at an average of 100 degrees C to create one cubic metre of water.

Multiple effect evaporation desalination (MED) needs about 2 kWh of electrical energy plus 80.6 kWh of heat at 70 degrees C for the production of one cubic metre of water.

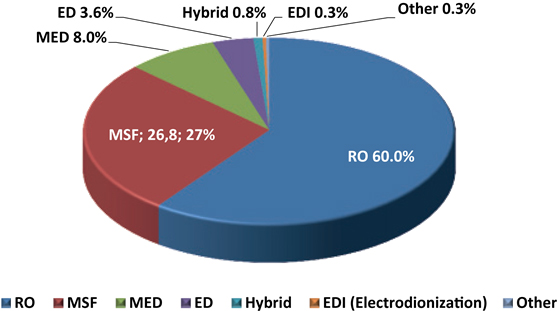

Figure 3 shows the use of the various desalination technologies being used and RO currently has 60 percent of the market, with MSF at 27 percent and MED with an 8 percent market share. MED requires 55 percent less electrical energy than RO and 33 percent less electrical energy than MSF. Furthermore, MED requires the same amount of heat as MSF (80.61 kW/m3), but at only 70°C. This brings the heat source for an MED plant within the scope of using a heat pump to convert low grade latent heat of condensation of steam to a heat source for an MED plant.

Figure 3: Desalination Technology Market (IDA in Koschikowski, 2011)

Steam Power Plants

Steam Power Plants (SPPs) are inherently inefficient. The heat rate for SPPs depends on the fuel source. See Table 2.

Table 2. Average operating heat rate for selected energy sources

|

Year |

Coal |

Petroleum |

Natural Gas |

Nuclear |

|

2002 |

10,314 |

10,641 |

9,533 |

10,442 |

|

2004 |

10,331 |

10,571 |

8,647 |

10,428 |

|

2006 |

10,351 |

10,809 |

8,471 |

10,435 |

|

2008 |

10,378 |

11,015 |

8,305 |

10,452 |

|

2010 |

10,415 |

10,984 |

8,185 |

10,452 |

|

2012 |

10,498 |

10,991 |

8,039 |

10,479 |

Coal includes anthracite, bituminous, subbituminous and lignite coal. Waste coal and synthetic coal are included starting in 2002.

Petroleum includes distillate fuel oil (all diesel and No.1 and No.2 fuel oils), residual fuel oil (No.5 and No.6 fuels oil) and bunker C fuel oil, jet fuel, kerosene, petroleum coke, and waste oil.

Source: U.S. Energy Information Administration, Form EIA-023. “Power Plant Operations Report”.

For the purpose of this discussion we have taken the average of the six even numbered years 2002 – 2012 for petroleum SPPs as 10,835 Btu/kWh (11,431 kJ/kWh). As it takes 3,412 Btus of energy to produce one kWh, this means that only 31.5 percent of the energy in the fuel is converted to usable electrical energy, whilst the remaining 68.5 percent are losses due to radiation, friction, generator ventilation and last, but not least, heat in the exhaust steam going to the condenser, which is estimated at 60 percent of the total heat input. In equivalent terms this represents 1.9 kWh of heat per kWh of electrical energy which needs to be disposed of in the condenser. 2.85 litres of water would need to be evaporated per hour in the cooling tower, plus at least 15 percent bleed to remove this amount of heat in the steam condenser. This equates to 3.3 litres/h per kWh.

As mentioned at the end of the previous section it is not necessary to use cooling water to condense the exhaust steam from the final stage turbine. As long as a cold surface is provided for condensation the process is possible.

Refrigerated Steam Condensing

It is possible using a refrigeration process to provide a cold condensing surface. This has the advantage of no longer needing a cooling water system comprising pumps, cooling towers, and water treatment systems. This would save cooling water at the rate of about 3.3 litres per hour per kW electrical energy generated, including 15 percent bleed.

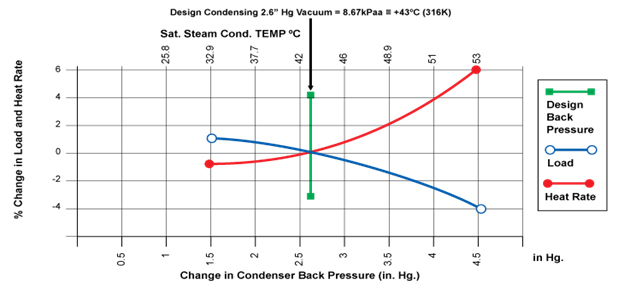

Referring to Figure 4, it is clear that a refrigerated condenser is able to maintain a steady condensing temperature which is independent of climatic influences on the cooling water temperature and thus the condensing temperature, which can vary widely in hot, humid climates.

If we set the heat pump discharge to a condensing temperature of say 70°C, we can generate 70°C hot water, which is hot enough as a heat source temperature for an MED plant. To maintain a condensing temperature of 43°C, the condenser surface temperature would need to be maintained at a temperature of about 38o C.

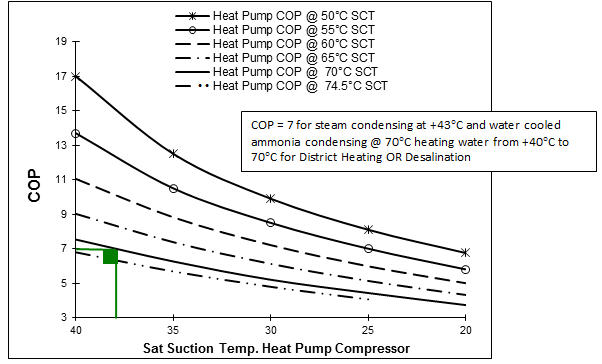

Referring to Figure 5, the COP of a refrigeration compressor is 7 at +38°C refrigerant evaporating temperature and +70°C refrigerant condensing. This means that the electrical energy required to handle a condensing heat load of 1.9 kW heat per kWh generated amounts to 1.9 ÷ 7 = 0.27 kWh, delivering a total heat of 2.17 kWh per kWh generated.

Source: Boyce, Mehervan P. Handbook for Cogeneration and Combined Cycle Power Plants, 2nd Edition. ISBN 978-0-7918-5953-7

Figure 4: Percent change in load and heat rate due to change in steam condensing pressure

Source: Johnson Controls Sabroe

Figure 5: Ammonia compressor heat pump COPs

The requirement is 80.6 kWh of heat/m3 of water produced in an MED plant. 2.17 kWh of heat plus 0.27 kWh would therefore produce 26.9 litres of water. This is the amount of water which would be produced as a by-product from one kWh generator output. The hourly water production from every MWh generator output would therefore be 26,900 litres (26.9 m3/hr) and the electrical energy consumption would be 270 kWh, i.e. 10 kWh/m3

Summary Of Water Production And Energy Consumption Characteristics

A heat pump cooled steam condenser at a Steam Power Plant (SPP) would have the following water production and energy consumption figures when supplying heat and energy to an MED plant.

- Produce water at the rate of 26.9 m3/h per MWh.

- Consume electrical energy at the rate of 10 kWh/m3. To this needs to be added 2 kWh/m3 to operate the MED plant itself. Thus the total electrical energy consumption would amount to 12 kWh/m3.

- 3.3 m3 of cooling tower generated cooling water would be saved per MWh power station output. Adding to this the 26.9 m3/hr generated by the MED process, the effective benefit would be a water production rate 30 m3/h per MWh SPP generating capacity.

- Hourly energy savings of an estimated 6 kWh per MWh would result when no longer needing to operate the cooling water system comprising pumps and cooling tower fans. /2/

The effective specific energy consumption would reduce by about 1 kWh/m3 to 11 kWh/m3 due to the combined impact of an effective water production increase of 3.3 m3/h and a reduction in cooling water system energy consumption.

- When it is not necessary to produce water these systems may be used to supply hot water to district heating systems in cooler climates. For example, in the EU heat pumps are classified as renewable energy and as such SPPs in the EU may become major heating suppliers to District Heating Systems employing heat pumps using the latent heat of condensation in steam as the heat source. The heat would be produced in an efficient manner and as such would very likely be a viable, and perhaps more importantly, a long term sustainable solution to provide heating as a by-product of electricity generation to large populations.

- The COP of the heat pump may be enhanced by multi-staging and/or economising of the compressors plus perhaps the addition of a Mechanical Vapour Recompression (MVR) stage at the front end of the MED plant.

Conclusions

Using heat pumps to condense steam in Steam Power Plants (SPPs) allows the recovery of waste heat at high efficiency. The amount of heat becoming available as useful heat at the discharge of the heat pump amounts to 150 percent to 200 percent of SPP electrical energy production. Heat rates vary from 8,500 to 10,800 BTUs/kWh. This heat may be used for different purposes like MED desalination and district heating. This basically means that up to 90 percent or more of the energy in the fuel consumed by the SPP is becoming available as usable energy. This represents great value for money when considering that SPPs normally dispose of their condensation heat directly into the environment via cooling water from cooling towers, rivers, lakes or the sea.

It is also worth noting that such systems may be retrofitted to existing SPPs for both MED and/or District Heating applications.

All the technologies involved – MED, district heating and heat pumps – are well established in their own right and it would not be too difficult to operate an MED plant with 70°C water generated by a steam condensing heat pump.

References

(1) Lee, Erika. 2010. “Pressing change”. Saudi Arabia and desalination. Harvard International Review, December 23, 2010. Accessed at http://hir.harvard.edu/pressing-change/saudi-arabia-and-desalination-0

(2) Gellings, C. et al. 2011. “Program on technology innovation: electricity use in the electric sector. Opportunities to enhance electric energy efficiency in the production and delivery of electricity”. Electric Power Research Institute (EPRI). 1024651 – Final Report, November 2011.