Top 10 Technologies From WEFTEC 2016

By Kevin Westerling,

@KevinOnWater

300,000 square feet. That was the size of the tradeshow floor at the Ernest N. Morial Convention Center in New Orleans for the recent 89th Annual Water Environment Federation Technical Exhibition and Conference (WEFTEC), the world's largest annual water quality exhibition. I logged many miles and copious notes over those three days in late September, but it would be folly to suggest that I saw and considered every technology showcased (over a thousand exhibitors were on hand). Instead, here’s a “best of” list from all that I came across — a snapshot of various technologies that stood out from the masses, exceptional for their level of innovation and potential for industry impact.

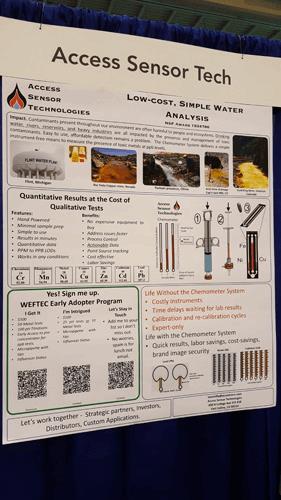

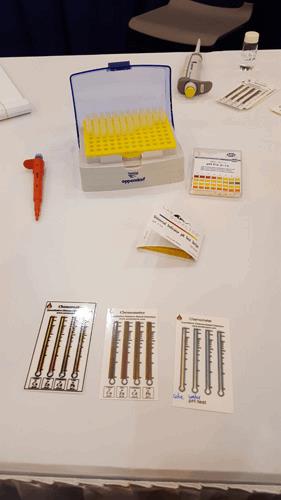

Chemometer System – Access Sensor Technologies

A natural place to start in the hunt for innovation is at the exhibition’s designated “Innovation Center,” which could act as a cheat-sheet for a list such as this. However, these areas tend to be more about catering to startup companies rather than hosting the most innovative technologies, which are in truth scattered throughout the exhibition. But this particular product separated itself from so many others of the “innovative” distinction in that you can see a clear and quick path to everyday use for water utilities.

Access Sensor Technologies’ innovation is a simple, inexpensive water sampling system that provides results within 10 minutes, working by merely placing a water drop on a tester the size of an index card. The specially formulated card(s) can be set up to test for a wide range of contaminants, pH, or other parameters. No training or instruments are required, and the easy-to-read results (displayed on a thermometer-style scale) are compatible with smartphone loggers or LIMS (laboratory information management systems). Tom Reilly, the company’s lead chemist, is inviting interested parties to contact him (tomreilly@accsensors.com) for pilot-trial opportunities.

Organics Destruction Cell (ODC) – Arvia Technology

It would be an oversight if the WEF 2016 Innovative Technology Award Winner wasn’t also mentioned here, given that it was deemed a cut above even the most cutting-edge competition. Arvia’s solution is a tertiary treatment step for the removal of micro-pollutants from wastewater, allowing for water reuse or zero liquid discharge (ZLD) by industrial users, or simply for micro-pollutant-free water effluent.

The ODC system is unique in that it combines advanced oxidation and adsorption in a single unit, the latter featuring a proprietary adsorbent (Nyex) that allows for oxidation to occur more efficiently. Arvia’s website summarizes the process: “When an electric current is applied across the two electrodes surrounding the Nyex, oxidation occurs throughout the entire unit, rather than just on the electrodes' surface, as is typical of electrochemical cells. The oxidation of the adsorbed contaminants and the regeneration of the Nyex happen simultaneously, allowing for a continuous process. As a result, the energy used for oxidation is proportional to the amount of organic to be treated, rather than the volume of wastewater. Therefore, the Arvia ODC system is ideal for removal of organic pollutants at low concentrations, including at ppb level.”

That may be the party line, but the product earns credibility for its award-winning turn at WEFTEC.

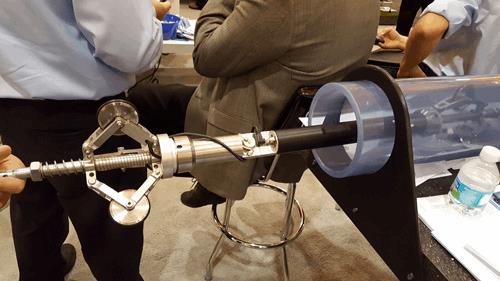

Accurate Mapping Probe (AMP) – CUES

Pipeline condition assessment and asset management are among the top concerns of water system operators, and a number of interesting devices for in-pipe inspection were on display at the show. The AMP stood out for providing ‘next level’ pipeline information in the form of 3D positional data. The autonomous system maps out the precise location of underground assets while identifying problems such as pipe sags, misaligned joints, and horizontal and vertical design problems, thus allowing for proactive and pinpoint repair and replacement. The data can be integrated into centralized systems and utilized to inform and/or justify spending decisions, schedule O&M activity, or to validate as-built drawings for record-keeping. Available in a multitude of models, the pictured DR 4.2 AMP is representative of the series’ range of application, suitable for pipes made of steel, concrete, PE, or PVC and inside pipe diameters from 3.5” to 58”.

Membrane Aerated Biofilm Reactor (MABR) – Emefcy Ltd.

You may have heard of MABR technology — not to be confused with two other advanced biological processes, a membrane bioreactor (MBR) or moving bed biofilm reactor (MBBR) — but there are very few companies that actually provide it. Following decades of R&D, Emefcy is the first to commercialize MABR, which reduces energy consumption typically required for aeration in secondary wastewater treatment, instead employing “passive aeration” through the unit. The Emefcy solution features spirally-wound membranes submerged in a tank, with wastewater fed continuously and effluent discharged by overflow. Course bubble diffusers provide aeration periodically, though at reduced, periodic intervals — a 90 percent energy reduction in energy compared to conventional aerobic wastewater treatment, in addition to 50 percent sludge reduction. Nitrification and denitrification is performed simultaneously, requiring less carbon than typical biological treatment, as well as very little operator involvement. The modular units are ideal for decentralized treatment (neighborhoods, resorts, rural villages, etc.), with scalable units that are odorless and noiseless.

Flygt Concertor – Flygt -- A Xylem Brand

The pump with a fancy name — from the Latin concentare, meaning “working together to orchestrate harmony” — the Concertor is the first wastewater pumping system with integrated intelligence. Or, as I was told, it’s a pump with a brain. Powered by a premium efficiency motor (the IE4) and featuring a smaller, simplified control system, the Concertor automatically finds the energy ‘sweet spot’ without the need for variable frequency drives (VFDs), freeing up valuable physical space at the plant. It also adjusts to varying conditions, relinquishing the need to set up numerous pump stations with settings devoted to different jobs. According to Flygt, these attributes provide 70 percent energy savings versus conventional pumping systems while reducing pump inventory by up to 80 percent. Other ‘brainy’ benefits include self-cleaning functions for odor control and reduced maintenance, automated detection and clearing of clogs, self-monitoring with overheat prevention, and automatic rotation-setting to prevent incorrect impeller rotation.

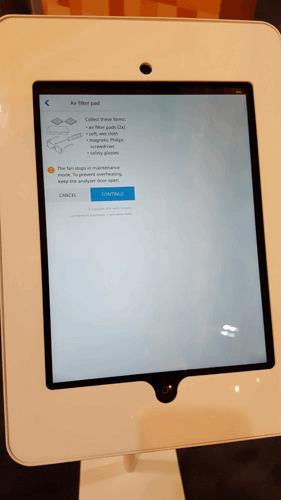

Mobile Sensor Management – Hach Company

It’s an objective fact that Hach instrumentation products are pretty ubiquitous in the water/wastewater space, and now the supplier of these instruments is making them much easier to access, manage, and own. Hach has introduced Mobile Sensor Management for operators to get sensor performance data and maintenance updates from a dedicated smartphone app. Sensors can be checked (against lab results) and adjusted from the app, which also provides notifications for when maintenance is needed. As personnel arrive for maintenance, the app provides step-by-step instructions for how to complete the job — no more digging up manuals. Mobile Sensor Management simplifies and improves instrumentation O&M, providing cost benefits as well as performance assurances for maintaining water quality and regulatory compliance.

Hydro MicroScreen – Hydro International

They say time is money, but you could also say space is money — especially when it comes to industrial applications. Hydro International’s new rotating belt screen not only saves plant space, but has multiple cost-saving advantages over conventional solids-removal systems, according to the company. The Hydro MicroScreen can replace primary clarification altogether or consolidate multi-step pretreatment processes into a single step, with savings realized by decreasing energy and chemical use as well as the costs associated with maintenance and solids handling and disposal. The unique design allows solids to form evenly on the screen as wastewater passes through and fills the influent chamber; meanwhile, an ultrasonic level sensor inside the chamber controls the screen’s rotation, ultimately discarding the solids by simple gravity into a screw auger. As it’s rotated, the screen is cleaned to begin the process again.

Typical results are 2 to 4 percent total solids (TS), similar to conventional primary sludge and useful for digestion and other thermal conversion processes. With the addition of a compression zone and dewatering section to the screw auger, up to 50 percent TS can be achieved with no chemicals required. Other reported performance stats include 60 to 70 percent removal of total suspended solids (TSS), 30 to 40 percent removal of biochemical oxygen demand (BOD) without negatively impacting food-to-microorganism (F/M) ratios, and 30 to 40 percent removal of fats, oils, and grease (FOG). With a capacity of 1,750 gpm (2.5 MGD), the unit can often reduce footprint requirements by up to 90 percent, decrease energy requirements by up to 50 percent, and offer a one-year return on investment.

GasMix Anaerobic Digester Mixing System – Landia, Inc.

Sometimes innovation is hard to appreciate, and that which seems simple is actually an engineering feat. Such is the case with GasMix, the first mixing system for anaerobic digesters that is mounted on the outside of the tank. While most systems rely on hydraulic mixing that requires rotating equipment within the tank — and therefore maintenance in the tank — Landia spares the interior for more efficient gas mixing with improved cell breakdown and increased methane concentrations. Furthermore, no inside equipment means a safer environment for plant personnel who no longer have to enter the tank for maintenance. In fact, there is no need for access walkways, platforms, or joists, thereby reducing capital costs.

The video below shows the three-dimensional mixing pattern at work, featuring a Landia non-clog chopper pump (with 20-year lifespan) to draw sludge and pump it through the aspirating venturi chamber. The system, which can be retrofitted to existing tanks, is ideally suited for municipal wastewater treatment or food processing plants.

Wireless IoT Sensors For Water Monitoring – Telog Instruments (part of Trimble Water)

Analytics. Smart water. The Internet of Things (IoT). These are terms bandied about by companies and utilities at the top of the innovation adoption curve. Complete system visibility, facilitated by remote measurements at points throughout a water or wastewater network, will one day be par for the course for utilities. The trouble is the transition — the cost and equipment challenges related to moving to this future model. The Telog 41 Series of wireless, battery-powered sensors puts remote monitoring within easy reach, utilizing low-power, long-range (LoRa) wireless communications technology on the LoRaWAN wide-area network. According to Telog, the LoRaWAN specification “enables seamless interoperability among IoT sensors without the need for complex local installations to enable the rollout of IoT applications such as the monitoring of water pressures, water levels, rainfall, and metered flow volumes.”

Telog offers a range of different sensors dedicated to the above-mentioned applications, but all share the following benefits:

- Low cost compared to traditional cellular remote monitoring products, enabling greater deployment

- Automated event detection and reporting through configurable alerts and alarms

- User-replaceable, C-size lithium battery power (eliminating need for on-site power) with four- to seven-year battery life

- Simple installation and maintenance

- Compatibility with Telog’s cloud-hosted and on-premise software

Continuous Deammonification (conDEA) – World Water Works

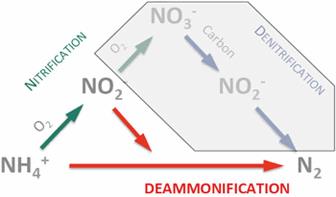

First there was nitrification/denitrification, which is still considered conventional or traditional nitrogen removal technology. Then came “shortcut” nitrogen removal, or nitritation/denitritation, which requires less energy and carbon while also producing less sludge than its forebear. The next step in the evolution of energy-efficient, low-cost nitrogen removal — an even shorter cut, with better results — is continuous deammonification, or what World Water Works calls conDEA.

This new process involves the partial nitritation of ammonia followed by anaerobic oxidation of residual ammonia and nitrite to nitrogen gas by anammox bacteria. Because less ammonia is being converted to nitrite, energy consumption is reduced by more than 60 percent (0.45 to 0.79 kWh/lb of nitrogen removed) compared to the traditional scheme (1.8 to 2.7 kWh/lb), while sludge is reduced by more than 80 percent. It is also a “green” technology with zero carbon footprint and zero chemicals required.

conDEA is the first anammox system to reach North America and the lowest-cost total nitrogen (TN) removal technology currently available, according to World Water Works. Its prime applications include high-strength industrial streams or municipal wastewater sidestreams.

Do these solutions address your particular challenges? Discuss below, or contact me (editor@wateronline.com) with suggestions on the industry issues and technologies you would like to learn more about.