The Case For Condition Assessment

By Bryon Livingston, PE, senior project engineer and Derek Wurst, PE. condition assessment manager, Black & Veatch

The need for using condition assessment as part of an overall asset management program has been documented over the past two decades, but the value of this work for the cost has eluded many utilities.

The AWWA’s 2001 Dawn of the Replacement Era: Reinvesting in Drinking Water Infrastructure report identified concerns about the age of infrastructure in the U.S. and outlined the need for condition assessment and reinvestment in our pipelines. Increased understanding and application of asset management principles over the past 15 years is changing the way we think about monitoring, managing risk, and prioritizing capital investment. To effectively manage any asset, we first must know something about its current condition. Assessing the condition of buried infrastructure, especially the critical pipelines we depend on to reliably deliver water, is not as difficult as it may seem, but it does require a practical, programmatic approach.

Condition Assessment Defined

The U.S. EPA defines condition assessment as “the collection of data and information through direct and/or indirect methods, followed by analysis of the data and information, to make a determination of the current and/or future … status of the pipeline.” (EPA/600/S-09/003 April 2007) The amount of data required to conduct a condition assessment varies with the risk of failure associated with the pipeline. Indirect testing methods such as close interval potential survey (CIPS) or other soil corrosion potential measurements area adequate for low-risk pipelines, but high-risk pipelines require direct testing to collect measurements of pipe wall thickness; many pipelines require some level of testing between the two, depending on the risk of failure for a particular pipeline.

The EPA’s 2007 publication, Distribution System Inventory, Integrity and Water Quality, reported that condition assessment was at the time either not used or not used routinely by most utilities, and utilities often had limited data about their systems besides what was installed and when it was installed. Where analyses have been conducted, it is common to see qualitative indicators such as “good” and “poor” assigned to pipes in the system. These indicators do not help utilities plan and schedule future improvement nor identify quantitative indicators such as “remaining useful life” that could be used to do so. Many water utilities are unsure of the effectiveness of advanced inspection techniques, such as electromagnetics, and want inspection data that is collected through these techniques validated by physical inspection before they readily accept such data. Potential users of advanced inspection technologies may need more information about the benefits received by implementing such technology to justify the cost.

Condition Assessment Applied To Asset Management

Earlier this year AWWA shared findings from its 2015 Establishing the Level of Progress in Utility Asset Management Survey. The report includes summaries and analyses of reported asset management practices collected from the survey of 545 utilities across the U.S. and Canada.

Question 14 of the AWWA survey asked, “Does the organization have a process in place to assess the condition of linear assets (distribution system pipes) and store the condition data in a spreadsheet or database?” The response indicated 63 percent are at least somewhat engaged in the practice, and about half of those (33 percent of total respondents) are using historic leak data as the basis. Only 13 percent of the respondents reported using advanced condition assessment techniques on critical pipelines.

Collectively, these and other surveys and studies show that despite an increased use of condition assessment since 2001, utilities don’t always apply the process as effectively as possible. The majority of water utilities have an annual repair or replacement method in place, using various methods to identify which pipelines to repair or replace each year. Although a majority of utilities plan to incorporate condition assessment into their overall pipeline management programs, relatively few have a programmatic approach in place to guide the implementation of condition assessment. Identification of critical pipelines using risk analysis is a key first step in implementing a condition assessment program. And, as indicated in the 2015 AWWA survey, relatively few respondents use available advanced condition assessment technologies, such as electromagnetic testing.

Figure 1. Ultrasonic and guided wave testing equipment

Reactive Condition Assessment Programs

The main goal for condition assessment is to prevent a catastrophic failure of a critical pipeline that results in significant loss of service and expense. So why don’t more utilities use condition assessments to develop repair and replacement programs? Possible reasons include expense, potential disruption to operations, and required modifications to the piping. Fear of change — especially if the process seems to be working well for now — is another potential reason why some might avoid condition assessment.

Utilities tend to establish a proactive and aggressive program for condition assessment after they have experienced a catastrophic failure and experienced political and social pressure to prevent more failures. Although it is difficult to obtain funding to invest in buried infrastructure, the growing evidence from pipe failures across the U.S. gives credence to acting proactively to avoid major problems. Condition assessment enables utilities to make informed decisions about pipeline management armed with the knowledge to understand the risk.

Moving From Reactive To Proactive

The value of condition assessment is best illustrated by examples.

One example is a steel lock-bar pipe installed in the 1920s. The pipe originally had a coal-tar enamel coating but was relined with cement mortar in the 1960s. The pipeline was selected for inspection through a risk-based process based on its age and high consequence of failure.

The pipeline was inspected internally while it remained in operation using a camera specifically designed for insertion into potable water mains. In addition, external, nondestructive testing (ultrasonic thickness, guided wave, and broadband electromagnetic testing), visual inspections, soil corrosivity testing, and a geotechnical evaluation of the pipeline alignment were performed to document liner integrity, structural integrity, and other localized defects that can affect pipeline reliability and/or serviceability.

Data collection and subsequent engineering evaluations enabled the assessment team to determine the current condition of the pipeline, estimate its remaining service life, and identify rehabilitation needs. Condition assessment revealed that despite mortar-lining deficiencies, the pipeline has sufficient thickness to withstand internal and external loads and will provide long-term reliable service.

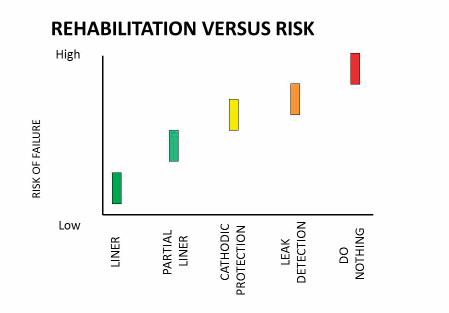

Recommendations also included spot repairs to the cement mortar lining rather than full liner replacement after the two options were compared by calculating their equivalent uniform annual costs. The spot repairs were deemed to be the preferred alternative based on a life-cycle cost perspective. Ultimately, condition assessment revealed that the pipe had sufficient estimated remaining service life to justify mortar-lining spot repairs. The assessment and findings enabled the owner to prioritize capital-improvement resources, improve pipeline reliability, and mitigate risk (Figure 2).

Another example is a prestressed concrete cylinder pipeline (PCCP) installed in the 1970s with pipe made with Class IV prestressing wire, which is known for being susceptible to failure. Risk analysis ranked this pipeline as the second most critical pipeline in the prioritization plan. Inspection required coordination with a shutdown of the treatment plant and installation of access taps for the inspection equipment (Figure 3). Due to the high-risk ranking and potential for failure, the entire pipeline was inspected with electromagnetic inspection technology and a closed-circuit television (CCTV) camera that was inserted into the pipeline (Figure 4). Condition assessment revealed no pipe segments with broken prestressing wires and no observed defects. The results, which were not anticipated given the historical high rate of failure in this specific pipe type, enabled the utility to focus available funding in the most appropriate way on other priority pipelines.

Figure 2. Evaluation of risks

More Knowledge Is A Valuable Thing

Condition assessment is an important component of asset management, but it also has value in the annual budgeting process to determine which pipelines should be replaced each year. As demonstrated by the 2015 AWWA survey, many utilities budget funds each year for replacement of pipelines based only upon age or leak history. The value of condition assessment is in the process of prioritizing risks to determine the level of data collection required for a particular pipeline and then inspecting the highest-priority pipelines. Condition assessment can be relatively inexpensive for indirect methods or a desktop analysis or more costly for a comprehensive field inspection to gather direct condition data. High-priority pipelines justify more data collection, whereas medium- and low-ranking pipelines may only call for indirect testing and possibly data collection at selected locations based on the results of indirect testing. A phased approach for data collection allows utilities to adjust the amount of data collected to address the level of risk they are willing to accept. The cost of condition assessment increases with the amount of data collected.

Figure 3. Installing the tap saddle on pipeline for access

Figure 4. Insertion of the inspection tool

It is difficult to justify the cost of condition assessment without having a process in place to compare the cost of the assessment with the expected benefit. Knowing the condition of high-priority infrastructure can reduce the risk of catastrophic failures and the associated high costs. Knowing the condition can also prevent utilities from needlessly replacing pipeline based on assumptions when limited repair or rehabilitation might be sufficient and make more sense financially, as indicated by the examples. Condition assessment can be justified by considering the value of selective replacement of pipelines based on known condition.

The Black & Veatch 2016 Strategic Directions: Water Industry Report describes a process employed by the Tulsa Metropolitan Utility Authority (TMUA) in Oklahoma. TMUA is using advanced analytics and improved collaboration to make informed investment decisions. Understanding which projects can be deferred and how deferred projects affect overall risks helps cities like Tulsa prioritize and optimize capital; knowing the true, versus suspected, condition of buried assets is an important step in determining where limited capital improvement dollars will do the most good.

Making the determination to rehabilitate, replace, or do nothing to pipelines and other assets on the basis of field-verified data yields a better capital improvement plan. The amount of data required is determined by the priority of the pipeline from the risk-analysis program. Capital investment decisions based on condition assessment results are more cost-effective and valuable in mitigating risk than decisions based on leak history and age alone.

About The Authors

Bryon Livingston is a senior project engineer at Black & Veatch with more than 35 years of experience, including several years in municipal and industrial operations. He specializes in condition assessment and rehabilitation of buried infrastructure and has extensive project experience in the condition assessment, design, rehabilitation, and construction of solutions in water transmission and wastewater collection.

Bryon Livingston is a senior project engineer at Black & Veatch with more than 35 years of experience, including several years in municipal and industrial operations. He specializes in condition assessment and rehabilitation of buried infrastructure and has extensive project experience in the condition assessment, design, rehabilitation, and construction of solutions in water transmission and wastewater collection.

Derek Wurst is a condition assessment manager at Black & Veatch and has dedicated his career to the assessment of water and wastewater infrastructure to help clients extend the useful life of their assets. He has more than 15 years of focused condition assessment experience in the evaluation of water and wastewater facilities. Wurst has directed and provided technical assistance in the analysis of water transmission, wastewater and stormwater collection systems, pipelines, pump stations, and treatment facilities.

Derek Wurst is a condition assessment manager at Black & Veatch and has dedicated his career to the assessment of water and wastewater infrastructure to help clients extend the useful life of their assets. He has more than 15 years of focused condition assessment experience in the evaluation of water and wastewater facilities. Wurst has directed and provided technical assistance in the analysis of water transmission, wastewater and stormwater collection systems, pipelines, pump stations, and treatment facilities.