Replacing The Right Main At The Right Time

By Ryan Flynn, senior principal engineer with the distribution engineering section Tacoma Water

The 100-year main replacement cycle isn’t always best — it can lead to replacing mains that have years of remaining useful life.

With an interest in keeping rates low and a desire to effectively manage an aging distribution system, municipalities are beginning to utilize asset management principles and condition assessment testing to strategically replace the right mains at the right time.

Tacoma Water, a regional water purveyor serving approximately 300,000 people in Tacoma, WA and neighboring communities, was founded in 1893 and owns and operates over 1,200 miles of distribution water mains. The distribution system comprises a mixture of cast iron, ductile iron, and asbestos cement water mains.

To address an aging distribution system, Tacoma Water implemented a main replacement program in 1995. Funding for the program was steadily increased over time with the goal of reaching a 100-year replacement cycle for distribution mains. By the 2011/2012 biennium, the main replacement had a biennial budget of $18 million and was replacing 10 to 12 miles of distribution main per year.

Selection of main segments for replacement was largely based on the age of mains, material class, and frequency of main breaks. Further, entire material classes such as asbestos cement were considered to be at the end of their useful life based on a handful of significant main breaks.

While the conventional 100-year replacement cycle can be easy to communicate to the public and policy makers, reliance on this cycle can lead to replacing mains that have years of remaining useful life. The issue with the sole reliance upon a 100-year replacement cycle is that it does not take into account the risk of not replacing the mains.

Tacoma Water continues to have a very flat break rate, approximately 4 breaks per 100 miles of main each year. This suggests that current failures are random and not affected by age.

Asset Management Plan

In 2011, to quantify risk and better answer the question of “What if you don’t replace it?” Tacoma Water developed a strategic asset management plan (SAMP) for distribution mains. The SAMP integrated two key asset management principles:

- understanding and accounting for risk; and

- managing assets to the lowest life cycle cost.

Understanding And Accounting For Risk

Utilizing the risk equation, where risk equals the likelihood of failure times the consequence of failure, Tacoma Water developed criteria for the likelihood and consequence of failure for each main segment. Development of the criteria included:

- Plotting failure curves for each main class based upon Tacoma Water’s maintenance and main break records. No longer do we have a 100-year replacement cycle as the basis for selecting mains. Main classes thought to have no remaining useful life, such as asbestos cement, are now considered to have remaining life based upon failure curves generated through this exercise.

- Interviewing staff to determine which main segments “kept them up at night” with concern for what a main failure might look like.

- Identifying areas within the distribution system with a high consequence of failure, such as geologic hazard areas, areas of known or suspected contamination, and areas with high customer cost impact.

- Establishing costs for minor, major, and catastrophic failures and determining the probability of such failures based upon Tacoma Water’s records. Tacoma Water conducted an assessment of costs associated with main breaks. From 2004 through 2014, Tacoma Water experienced 516 main breaks, with the average cost of a main break equaling $4,441.22. Ninety-five percent of the main breaks during the period cost less than $10,000.

Managing Assets To The Lowest Life Cycle Cost

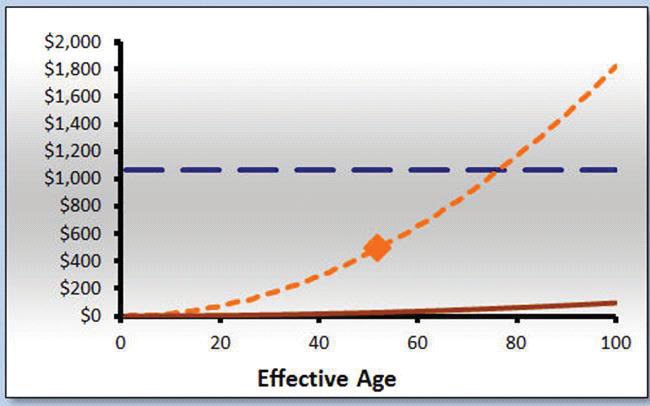

The criteria are then inserted into Tacoma Water’s life cycle cost model (shown below), which evaluates each of the 56,000 main segments in the distribution system to determine the optimal time for replacement. For each main segment, a remaining economic life is generated, indicating estimated time until the annual risk cost of operating a main is equal to the annualized cost of the asset’s replacement.

Tacoma Water’s life cycle cost model.

Optimal replacement timing is determined to be the age at which the annual risk cost of the asset (shown in orange) is equal to or greater than the annualized replacement cost of the new asset (shown in blue). The annual risk cost of the new asset is represented by the brown line.

The intersection of the orange and blue lines indicates the optimal time for replacement. Operating an existing water main beyond this intersection means the utility is taking excess risk. Whereas replacing the main prior to the intersection means the value of the asset will not be fully realized.

Incorporating Condition Assessment

The output from the economic model provides a prioritized list of main segments based on their remaining economic life. As the prioritized list was generated using a generalized failure curve developed from the maintenance and repair histories for their respective material class, further analysis is conducted to ensure the replacement of the main segments is warranted.

Pipe breaks can be prevented if the right data is collected before they happen.

To confirm the replacement recommendations, Tacoma Water utilized non-invasive acoustic condition assessment technology to conduct condition assessment testing on cast iron and asbestos cement water mains. The assessment technology was selected based upon the short time by which the analysis was completed and the ability of the technology to conduct analysis without service interruption to customers.

By combining the output of the economic model with condition assessment technology, Tacoma Water is provided with quantifiable data that can be used to develop business case justification for main replacement projects. In addition, and perhaps even more important, is that replacing main segments can be deferred if the condition assessment indicates replacement is not warranted at this time. In doing so, our rate payers are able to realize more value from existing assets rather than replacing assets too early.

Through the use of asset management principles by implementation of the SAMP and use of condition assessment technology, Tacoma Water is able to optimally time the replacement of our water mains. In so doing, Tacoma Water will have reduced the capital budget for the main replacement program from $18 million during the 2011/2012 biennium to $9 million in the 2015/2016 biennium.

Ryan Flynn has worked for Tacoma Water since 2006. As a senior principal engineer with the distribution engineering section, Flynn is responsible for the main replacement program and serves as the lead for the distribution main strategic asset management plan.