Nontraditional Nutrient Reduction Techniques

By Michele Braas, PE, RETTEW

It always feels good to meet your goals — even better to exceed them. Learn how an upgrade to biological nutrient removal (BNR) resulted in enhanced nutrient removal (ENR) performance.

In recent years, many municipal wastewater treatment plants have needed to update processes and facilities to comply with more stringent environmental regulations related to cleaning up local bays and streams. For the Manheim Area Water & Sewer Authority (MAWSA), formerly known as Manheim Borough Authority, located in Lancaster County, PA, the operators took on the challenge of upgrading to BNR effluent levels. The organization reached Pennsylvania Department of Environmental Protection (PADEP) standards after installing a new facility and processes, and then went on to tweak processes through trial and error, achieving ENR with impressively low effluent levels.

The History

Nearly 10 years ago, the PADEP met with MAWSA and its wastewater engineer, RETTEW, to review the agency’s strategy. The ultimate goal for the PADEP was to improve conditions in the Chesapeake Bay Watershed. The environmental agency set new total nitrogen and total phosphorus effluent limits for wastewater treatment plant (WWTP) discharges in Pennsylvania. MAWSA’s WWTP would need to achieve an average of 6.0 mg/L total nitrogen and 0.8 mg/L total phosphorus discharge concentrations, based on the permitted flow for the facility. At that time, MAWSA operated a trickling filter plant, which could not meet the proposed nutrient limits without additional equipment and procedures.

After evaluating future needs, MAWSA and RETTEW analyzed alternatives such as sequencing batch reactors and fixed film filters. RETTEW recommended a phased oxidation ditch and integral anoxic tanks for MAWSA’s BNR upgrade. The oxidation ditch is a continuous flow activated sludge system, with the main treatment processes isolated in separate oxidation ditches. The conditions of each ditch are altered between aerobic and anoxic conditions, thus achieving the desired treatment level. The recommendation also included an anaerobic selector for biological phosphorus removal. Other proposed upgrades included new return sludge and waste-activated sludge pumps, new variablespeed drives on influent pumps, two new final clarifiers, a supplemental carbon feed facility, a ferric chloride chemical feed system, and a biosolids storage facility. These changes would not only help MAWSA meet PADEP’s goals but also prepare it to meet more rigorous discharge levels in the future if needed.

The Upgrades

Released for construction bidding in mid-2009, the upgrades were slated for completion in 2011, meeting the PADEP’s mandated timing of April 2012. The engineering design specified all upgrades to be installed on the same property as the existing facility, and treatment operations needed to remain continuous throughout the construction and installation. Undertaken by Wickersham Construction and Engineering, Inc. and Gettle, Inc., the contractors adhered to the schedule, allowing the new commissioning procedures to occur simultaneously with the decommissioning of the existing facilities.

Throughout the construction process, some unforeseen challenges surfaced. During excavation, the team discovered the underground presence of several unmarked and abandoned vaults and structures. These items were not shown on the as-built drawings. The contractor worked with RETTEW to modify the construction approach, completing the base for the oxidation ditch in three concrete foundation pours while the structures were simultaneously removed.

Because of the close proximity to a nearby creek, groundwater also became an issue during excavations and construction. The contractor brought in large pumps to dewater the excavations for the oxidation ditch and kept the project on schedule and within the original cost estimates.

The original estimate of construction costs for the work was $10.4 million. However, approximate total cost after bids were returned was $8.6 million. With the change orders and change in construction approach due to the unforeseen circumstances, the final costs were approximately $9.6 million.

Plant improvements included new pumps for return sludge and waste-activated sludge.

The Process

The newly installed BRN processes enabled the facility to meet PADEP nutrient discharge requirements. BNR typically refers to a system treating wastewater to an effluent level of total nitrogen 8 to 10 mg/L and total phosphorus 1 to 3 mg/L. In a BNR wastewater treatment facility, the microorganisms used to treat the wastewater are intentionally stressed, resulting in several nutrient-important results: the conversion of ammonia to nitrates and nitrites, the release of nitrogen gas, and the uptake of phosphorus. To ensure these biological conversions occur, the microorganisms’ environment must be controlled, keeping the pH balance, alkalinity, carbon, and sludge age at correct levels. By controlling the microorganisms, their environment, and the phases of the installed oxidation ditches, MAWSA completes biological nitrogen removal through nitrification/ denitrification, as well as some biological phosphorus removal.

The Next Step

ENR is a step further than BNR, resulting in effluent levels as low as total nitrogen of 3 mg/L and total phosphorus of 0.3 mg/L or less. Traditionally, wastewater treatment facilities obtain ENR with the addition of filters or chemicals. At MAWSA, however, the facility’s staff has been able to reach ENR-level discharges through optimizing its oxidation ditches.

The authority’s staff wanted to optimize the facility for its primary discharge requirements, so they tested and finetuned processes to reach lower effluent discharge levels. The goals were both to improve effluent discharge levels and find operating and cost efficiencies for the facility, something that was possible because of the facility’s unusual quality influent.

MAWSA’s facility does not feature typical quality influent. Rather, its influent has low biochemical oxygen demand (BOD) concentrations, featuring monthly averages of 160 mg/L, with lows as little as 50 mg/L. These concentrations result in a low food-to-microorganism ratio. After careful testing of the process, MAWSA determined that by operating at an older sludge age, it was able to compensate for the low food-to-microorganism ratio, as older microorganisms require less food than younger ones.

MAWSA now operates with a sludge age of 40 to 50 days, while a typical oxidation ditch will operate with a sludge age of 20 to 30 days. This environment, which supports an older sludge age, allows MAWSA to meet ENR conditions within its existing oxidation ditch process, during which nitrogen removal is obtained biologically. Phosphorus is also partially obtained biologically but also via chemical participation in the clarifiers.

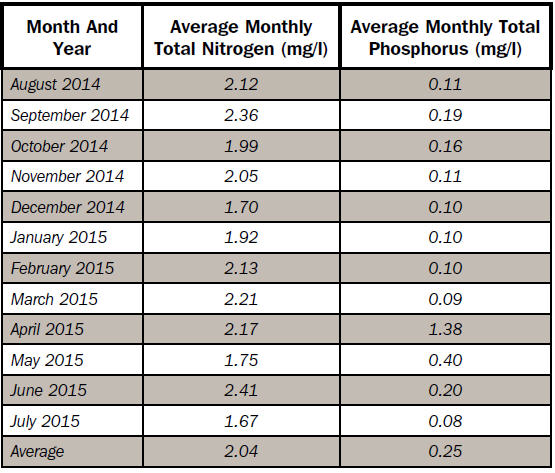

MAWSA’s WWTP Effluent Quality Data

A summary of MAWSA’s treatment plant total nitrogen and total phosphorus concentrations from August 2014 through July 2015 (the most recent data available)

The Pros And Cons

Operating the oxidation ditches at an old sludge age has several advantages. The older microorganisms require less dissolved oxygen than younger microorganisms. These conditions result in an overall decrease in the need for aeration, which in turn equates to lower energy costs.

Also, as a result of the extended sludge age and hydraulic retention time, the microorganisms actually use their own protoplasm as food. They do this through a process known as endogenous respiration, when a living organism uses its own cellular mass instead of outside organic matter for energy. This results in less sludge per pound of carbonaceous oxidation. This brings down overall sludge production, resulting in reduced disposal, chemical, and electrical costs for biosolids.

Operating at higher sludge ages, however, is not without its disadvantages. The older microorganisms are less resilient than younger microorganisms. The system is therefore more prone to quantity and quality disturbances from changes in flow. In addition, older sludges are also more granular in shape, which increases the amount of time it takes to settle the sludge. The older sludges challenge the clarifier systems. To combat these issues, MAWSA adds ferric chloride to assist in settling in the clarifiers, which not only assists in settling the sludge but it also helps to remove phosphorus.

Wastewater enters oxidation ditches at MAWSA

Like any wastewater treatment system and process, operating the oxidation ditches at an old sludge age has it disadvantages and advantages. MAWSA has determined that for its system, the advantages outweigh the disadvantages. The high sludge age ensures maximum usage of the new facilities, which in turn led to ENR-level nutrient removal results. The average monthly effluent concentrations from August 2014 through July 2015 were 2.04 mg/L for total nitrogen and 0.25 mg/L for total phosphorus (as seen in MAWSA’s WWTP Effluent Quality Data table, on page 23)

By working together, the staff at MAWSA and the engineers at RETTEW have been able to blend the upgrades and process improvements to produce an excellent water quality effluent that exceeds the PADEP’s limits and MAWSA’s goals. This results in a positive outcome for the receiving stream in southeastern Pennsylvania, which is connected through a network of waterways to tributaries of the Chesapeake Bay. MAWSA’s emphasis on operational quality is benefiting end users via reduced costs as well as the environment, by contributing to improvements to the Chesapeake Bay.

About The Author

Michele Braas, PE, specializes in wastewater system and drinking water distribution system design. She has coordinated design of wastewater treatment facilities, including BNR evaluations, sanitary sewer systems, and sewage pumping stations. Her experience also includes the writing of permit applications, grant applications, and contract documents, and the performance of construction administration.

Michele Braas, PE, specializes in wastewater system and drinking water distribution system design. She has coordinated design of wastewater treatment facilities, including BNR evaluations, sanitary sewer systems, and sewage pumping stations. Her experience also includes the writing of permit applications, grant applications, and contract documents, and the performance of construction administration.