Monitoring Water Quality With UVC LEDs

By Hari Venugopalan, Crystal IS, Director of Product Management

Rapid detection of changes in water quality is critical in water delivery systems, wastewater treatment, and industrial plants for process optimization, environmental regulatory requirements, and consumer health. Spectroscopy using UVC LEDs is an emerging method to detect these changes as they occur. Instruments using UVC LEDs offer real-time information on water quality, which is used to optimize the UV dose and maximize energy savings in water treatment plants. In addition, fluorescence spectroscopy with UVC LEDs can detect extremely low levels of oil-in-water, which can be used as an early warning indicator in industrial settings.

Monitoring water quality in water treatment

UV disinfection is a common treatment method in drinking water treatment plants. These systems are designed around a target UV dose based on an expected UV transmittance (UVT) of water in the system. However, environmental changes such as sudden weather events, seasonal changes in source water composition, or unplanned changes in upstream treatment processes can affect UVT. Monitoring the actual UVT of the system in real time is key to ensuring that the UV dose is sufficient to inactivate pathogenic microorganisms.

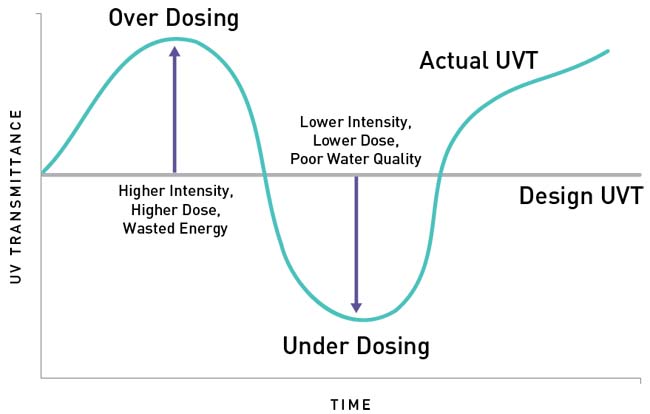

Figure 1: Effect of changes in UVT of water on energy consumption and dosing

When the actual UVT is lower than the expected UVT, the UV system does not deliver enough UV intensity to meet disinfection requirements. The water quality will suffer — presenting an immediate health risk to the community. In periods where the actual UVT is higher than expected, the UV system will deliver excessive UV intensity to disinfect the water, which translates into unnecessarily high energy consumption. For example, adjusting the UV intensity for a small change in UVT from 60 to 70 percent can result in an annual energy cost reduction by as much as 33 percent, depending on the size of the system. By monitoring real-time UVT, operators can optimize the UV dose in the system avoiding the consequences of under and over dosing.

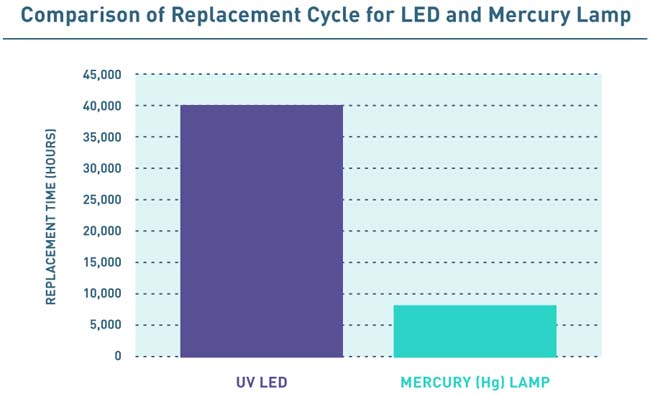

Traditionally, UVT monitors used mercury lamps for the UV light sources. Mercury lamps require a warm-up time to achieve stable measurement results, and so they are typically left on continuously. This leads to frequent lamp replacements. In contrast, UVC LEDs achieve full intensity instantly, allowing them to be on only when measurements are being taken, which preserves the overall life of the LED.

Figure 2: Comparison of time to replacement for Hg lamps and UVC LEDs. The mercury lamp is left on continuously while the UVC LED is operated at a 20 percent duty cycle.

The increased time between replacements coupled with other UVC LED benefits, such as low power consumption and monochromaticity, lead to lower system costs for UVC LED-based instruments. In addition, the compact footprint of the LED means smaller detectors that can monitor multiple points along the water treatment system: in a pipe, in an open channel, or as a battery operated handheld instrument. UVT monitoring can detect organic events upstream of the UV disinfection process and further reduce costs by reducing energy consumption, decreasing chemical consumption in coagulation, preventing membrane fouling, and extending the life of the carbon used in filtration.

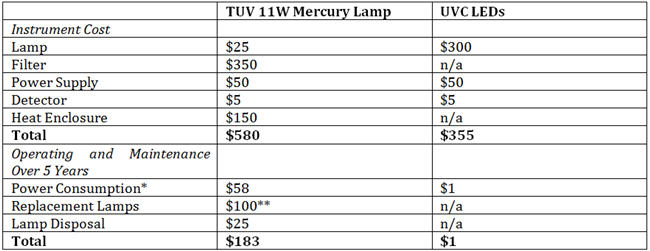

Table 1: Cost comparison of UVT monitor using a mercury lamp versus UVC LEDs

* Energy cost of $0.12/kWhr

**Four annual replacements for the mercury lamp at $25 each.

Oil-in-water monitoring in industrial applications

In industrial facilities, quick and reliable monitoring of hydrocarbons help prevent excess hydrocarbons from entering boilers, from exposure to the atmosphere in cooling towers, or from discharge into the sewer or environment in wastewater systems. Real-time monitoring of petroleum hydrocarbons in water reduces costs by allowing industries to avoid discharge or pollution fines and detect early leaks in systems, like heat exchangers, that lead to costly repairs.

The aromatic hydrocarbon proportion of a crude oil is highly fluorescent in the deep UV and therefore, fluorescence can be used to determine concentration. Fluorescence spectroscopy detects extremely low concentrations and has high specificity that allows users to distinguish between oil types. The sensitivity of fluorescence techniques is as much as 1,000 times higher than that of absorption spectroscopy, enabling measurement of concentrations in the part per billion levels.

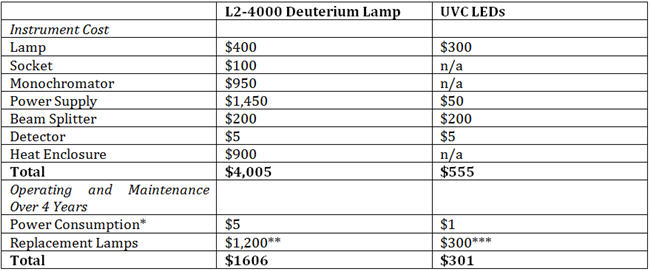

Traditionally, light sources used in these fluorometers for deep UV excitation were broad-spectrum light sources such as xenon flash or deuterium lamps. Compared to UVC LEDs, these sources are less stable, have more complex circuitry and require a complex optical design to filter out unwanted wavelengths. As seen in Table 2, this results in a high cost of ownership relative to instruments using UVC LEDs. The example assumes a deuterium lamp would be on 12 hours a day, 52 weeks a year and assumes four hours of sample measurement per day. The LED based fluorometer is operated at 100 mA for increased light output and sensitivity, but is only turned on for the four hours of measurement.

Table 2: Cost comparison of water quality monitor using a deuterium lamp versus UVC LEDs

* Energy cost of $0.12/kWhr

** Three annual replacements for the deuterium lamp at $400 each

*** One replacement of the LED

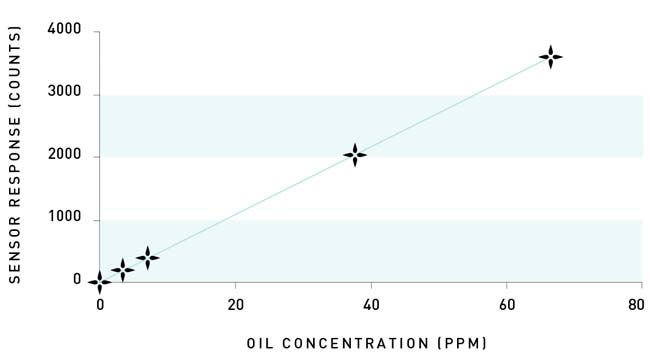

The reduction in component costs allows for more cost effective fluorometers without sacrificing performance. High performance UVC LEDs offer high light output, which allows for trace detection in the part-per-billion levels. Similarly, the spectral quality of the LED contributes to the linearity of measurement over four orders of magnitude.

Figure 3: Oil sensor response of UVC LED fluorometers demonstrating excellent linearity of measurement and extremely low detection levels.

The recent emergence of high performance UVC LEDs is leading to increased adoption of this solid-state light source in water and wastewater monitoring applications. UVC LEDs are driving innovations in instrument design for water quality monitoring which address key market trends around productivity, cost reduction, and miniaturization. As high performance UVC LEDs are available shorter wavelengths, the possibility of low cost smart water sensor networks for monitoring additional compounds, such as nitrates and other key environmental pollutants, becomes a reality.