EBMUD Successfully Manages Chloramine Residual In 10-Million-Gallon Reservoir With Chloramine Management System

Located on the eastern side of the San Francisco Bay, the East Bay Municipal Utility District (EBMUD) treats and distributes water to over 1.3 million customers in Alameda and Contra Costa counties. As one of the largest utility districts in California, EBMUD is a leader in the water industry’s water quality, conservation, and sustainability efforts.

EBMUD chloraminates water prior to distribution and uses chloramines for secondary disinfection in order to mitigate DBP (disinfection byproduct) formation. Chloramine, formed by reacting aqueous chlorine with ammonia, is a more stable disinfectant in distribution systems, but maintaining residual set‐points can be challenging for many utilities due to the complexities of chloramine chemistry in a distribution system. Once chloramine dosed water leaves a treatment plant, monochloramine degrades in distributions systems and free ammonia is released. Free ammonia is utilized by ammonia oxidizing bacteria which convert the ammonia into nitrites and nitrates further accelerating the monochloramine decay process. Additionally, the ongoing drought complicates water quality management for EBMUD and exacerbates residual and temperature stratification, nitrification, and taste and odor issues. All of these factors create the potential for the loss of increasingly precious quantities of stored water.

As utilities juggle water sources, particularly in the warmer summer months, free ammonia levels in distribution reservoirs can become elevated. Loss of chloramine residual can not only result in reduced pathogen control in distribution systems, but also create nitrification, taste and odor, and bacterial regrowth problems. Storage tanks pose particular problems to operators because detention times can be very long, resulting in substantial decay of the chloramine residual. Very poor water quality can require a utility to flush water mains or dump an entire tank — a painful outcome in water stressed California.

EBMUD’s distribution system is large and complex with multiple pressure zones and tanks. The 10-million-gallon Tice Reservoir (40 feet in height X 200 feet in diameter) is an above‐ground, welded steel tank that sits in the lower tier of a pressure zone cascade. Due to long residence times and low demand, Tice suffered from periodic episodes of degraded water quality.

In the summer of 2014, EBMUD engaged Process Solutions, Inc. (PSI) to pilot a Monoclor™ system designed to manage chloramine residual. The Monoclor system tackles the dynamic residual issue by simultaneously controlling three process parameters; (1) adding adequate mix energy to the tank to create and maintain homogeneous conditions (2) creating a high energy mix zone for the added chlorine and ammonia to fully react and (3) managing and maintaining the proper chemical dosing ratio with a combination of real time sampling and a proprietary dosing algorithm.

Monoclor trailer in place at Tice Reservoir

PSI provided a Monoclor trailer unit for a 4 month trial period. The trailer and PSI scope included a skid‐mounted Microclor® on‐site sodium hypochlorite generator (OSHG) that provided up to 40 pounds per day of chlorine (at ~0.8 percent concentration), a liquid ammonium sulfate skid, a total chlorine analyzer, and a 150 gallon per minute (GPM) Tank Shark® mixer which was placed inside of the reservoir. By using liquid ammonium sulfate and 0.8 percent sodium hypochlorite to generate monochloramine, a more stable monochloramine residual was achieved. The water booster pump and chemical metering pumps were all located inside the trailer with tubing leading to the reservoir and Tank Shark mixer. Installation of the Tank Shark mixer did not require divers or an outage because the unit was installed through the reservoir hatch without moving parts or electrical components. Utilizing the trailer option also simplified the permitting process for EBMUD and added flexibility for potential deployment to a different tank site.

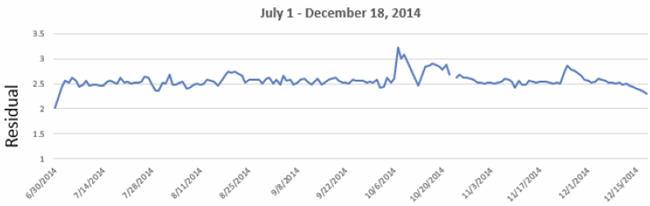

Residual set‐points were achieved and maintained in less than 48 hours. For the next six months, EBMUD and PSI monitored the performance of the Monoclor Tice Reservoir system and never experienced degraded water quality or had to take the tank out of service (see chart below). EBMUD has since purchased the Tice Reservoir Monoclor system and is expected to add additional units in the future.

EBMUD Tice Reservoir residual levels over six-month period with a Monoclor system