Benefits Of Treatability Studies In Design Of A Leachate Treatment System

By Sara Arabi and Andrew Lugowski, Conestoga-Rovers and Associates

The management of landfill leachate is a major engineering challenge. To design and operate an efficient leachate treatment system, which is essential to minimize the potential impact on the environment, several key factors such as the landfill waste characteristics, the local climate, the hydro geological conditions, and the landfill age must be considered. Landfill leachate characteristic is site-specific and varies from one site to the other. Bench- and pilot-scale treatability studies are valuable means for determining the feasibility of candidate treatment processes for landfill leachate treatment. Treatability studies yield basic design data for subsequent use in the design and optimization of the full-scale facilities.

Bench-scale treatability studies are performed in a laboratory on the actual leachate samples and the engineer can perform an array of tests in the field or in a laboratory. Pilot-scale treatability studies use scaled-down replicates of the full-scale system using actual continuous flow operations. Data derived from pilot-scale studies are useful for full-scale system design such as retention times, settling rates, chemical dosages, pH, and other operating and design parameters. Large and expensive full-scale systems are usually pilot tested to optimize the design and minimize risk. In addition, pilot tests can be used to identify potential operational problems such as scaling or sludge bulking. It also gives a unique opportunity to the operators to become familiar with the operations.

Two case examples of pilot plant studies for design of landfill leachate treatment systems are provided in this article. Pilot plant description, testing and operation and the benefits of the pilot plant study for the design of the full-scale system is presented below.

Case Example A - Biological Treatment for Organics and Ammonia Removal and Wetland Systems for Final Polishing

This Case Example involves the pilot plant study for treatment of leachate from a landfill designed for domestic, commercial, and non‑hazardous industrial wastes. An on-site Leachate Treatment Facility (LTF) implementation strategy was developed by the landfill owner to include passive treatment systems for leachate treatment. Bench-scale testing was conducted on three passive treatment technologies: constructed subsurface Vertical Flow Wetland (VFW), Waterloo Biofilter®; and Non-Membrane Bio-Filtration (Peat and Woodchip Filters).

The preliminary results of the bench-scale study identified that pretreatment of the leachate prior to entering the passive treatment system was required to prevent rapid iron fouling of the passive treatment system and to reduce BOD and ammonia concentrations. While the bench-scale studies indicated significant removal of pollutants of concern, i.e., BOD, TSS, ammonia, iron, and phenols, the effluent did not meet regulatory compliance. Three pretreatment systems were tested at the bench-scale including an Attached Growth Aerated Reactor (AAR), an Aerated Suspended Growth Reactor (ASR), and an Anaerobic Packed Bed Reactor (ANR). The AAR pretreatment system was found to be the preferred pretreatment technology based on the bench-scale results. Suspended growth activated sludge systems such as SBRs were not considered, at the owner’s request, due to higher number of pumps and more complex operation.

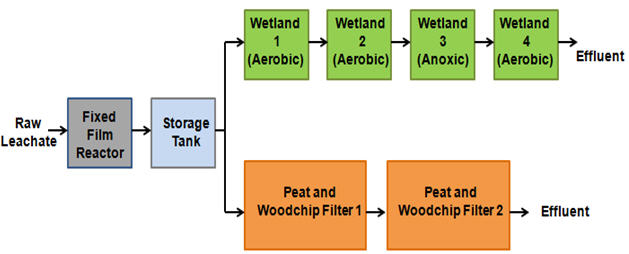

Based on favorable treatment results of the passive systems with pretreatment, a pilot plant study was implemented for the fixed film biological pretreatment and two passive treatment systems consisting of a 4-stage Constructed Wetland and a 2-stage Peat and Woodchip Filter system (Figure 1). The main objectives of the pilot plant study were to obtain more detailed performance data to assess the proposed systems, and determine other system-specific design parameters that were not addressed in the bench-scale study. Photograph 1 shows the storage and fixed film tanks and the wetland systems.

Figure 1. Case Example A: Schematic flow diagram of the pilot plant leachate treatment system

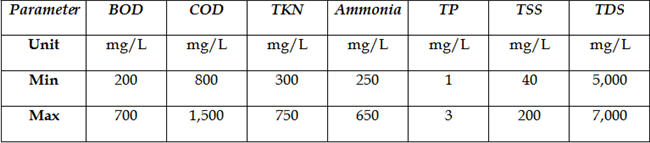

In order to monitor the fouling potential for the passive treatment technologies being evaluated at the pilot-scale, routine column testing was conducted on media samples from each unit of the Constructed Wetland and Peat and Woodchip Filters. The purpose of the testing was to determine media porosity, hydraulic conductivity, permeability, and a projection of long-term fouling rates. Respirometric studies were also conducted to determine the biokinetics of organic and nitrogen removal and obtain the fractionation of organic and nitrogenous compounds in the leachate. During the pilot plant study, significant data was collected on the raw leachate characteristics as presented in Table 1.

Photograph 1. Case Example A: Left – Storage and fixed film tanks; Right – Wetland systems

Table 1. Case Example A: Raw leachate characteristics

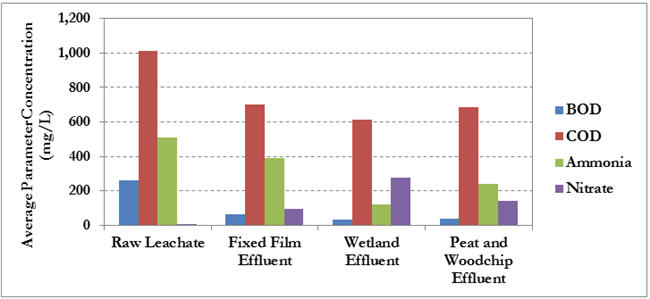

Six-month operation of the pilot plant system indicated that the fixed film biological pretreatment system has shown low biological activity and therefore has been ineffective at removing raw leachate BOD. The detailed analysis of the fixed film media samples indicated that attached growth was primarily inorganic. For the passive systems, the Peat and Woodchip Biofilter showed poor nitrification results with average effluent ammonia concentrations of 177 mg/L. The Constructed Wetland system showed some promising results during the warmer months, but the average effluent ammonia concentrations was 36 mg/L during the colder months. Although the Constructed Wetland has shown promising results, it failed to demonstrate a consistent capability to reduce ammonia concentrations below the expected discharge criteria of 1 mg/L. Figure 2 presents the profile of organics and nitrogen compounds in the pilot plant system.

Figure 2. Case Example A: Profile of organics and nitrogen compounds in the pilot plant system

The inconsistent performance of the Constructed Wetlands, combined with the need for mechanical pretreatment, has led the project to move forward with a plan to establish a stable, proven, and long term treatment option to accommodate potential future changes in the leachate quality and fulfill leachate treatment requirements at a higher organic loading. A Feasibility Study was conducted for the design of the full-scale LTF at a capacity of 120 m3/d for a suspended growth biological system to incorporate nitrification and denitrification. The main advantage of nitrification and denitrification processes for leachate treatment is the stable nitrification resulting from organic load dampening in the anoxic tank. Other advantages of nitrification and denitrification processes include removal of nitrate in the denitrification zone, reduction of oxygen demand, filament control, and improved sludge settlabilty. The processes evaluated in the Feasibility Study were the Modified- Ludzack Ettinger (MLE) and SBR. The conceptual design of the on-site LTF will be based on the outcome of the Feasibility Study.

Case Example B: Biological Treatment for Organics and Ammonia Removal for Discharge to a Local Wastewater Treatment Plant

This Case Example involves the pilot plant study for treatment of leachate from a landfill that receives non-hazardous solid waste from the Ottawa residents and businesses. CRA completed a pilot project of a BNR LTF as part of a study to determine whether a nitrification denitrification biological system could produce an effluent quality that met the sewer use by-law for indirect discharge to the City of Ottawa sanitary sewer. The pilot plant system consisted of four tanks: 1-5,000 L anoxic tank, 1-6,000 L aeration tank, 1-1,200 L clarifier tank and a waste activated sludge storage tank. The pilot plant was operated in MLE mode and designed for an overall HRT of 2.75 d (anoxic and aerobic HRTs of 30 and 36 hrs, respectively). Photograph 2 shows the three tanks for this pilot plant study.

Photograph 2. Case Example B: Process tanks for the pilot plant study

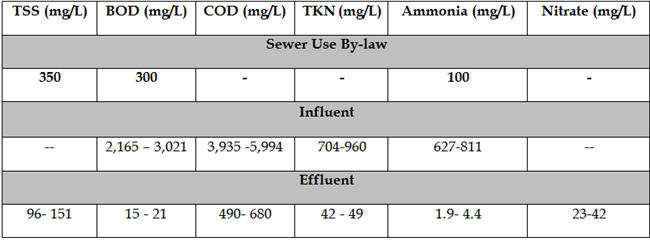

The pilot plant was operated at varying flow rates to determine the required HRT for sufficient leachate treatment. One of the objectives of the Pilot Plant study was to investigate the impact of high Total Dissolved Solids (TDS) on the performance of the biological system as the leachate was characterized by high TDS concentration up to 11,000 mg/L. The modelling of the nitrification denitrification process using BioWin indicated that to achieve satisfactory levels of denitrification, internal recycle between the aeration and anoxic tanks needed to be set at 10 times the influent flowrate. Phosphoric acid was added as a phosphorus source. Influent and effluent samples were collected to determine the effectiveness of the pilot plant system at various HRTs. Influent and effluent leachate quality is presented in Table 2 with City of Ottawa Sewer Use by-Law limits for key parameters shown.

Table 2. Case Example B: Influent and effluent leachate quality

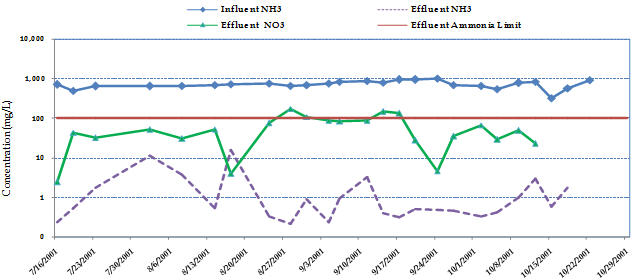

Based on the results shown in Table 2, the MLE process provided an effluent quality that met the sewer use by-law. The average effluent soluble BOD and ammonia concentrations were 20 mg/L and 2 mg/L, respectively, corresponding to 95% BOD and 99% ammonia removal efficiencies. Significant denitrification was also achieved resulting in effluent nitrate concentrations of 23 - 42 mg/L. Figure 3 presents the performance of the pilot plant in terms of nitrogen removal. The treatability studies indicated that high TDS concentration of 11,000 mg/L did not adversely impact the biological treatment of leachate and no pre-treatment for removal of metals and TDS was required for this pilot plant. The biological nitrification- denitrification was recommended for full-scale implementation. Due to modifications to operational plans for the site and evolving discharge requirements, a full-scale plant has not been constructed to date.

Figure 3. Case Example B: Anoxic/aerobic pilot plant results —indirect discharge