AccuFAS Submerged Fixed-Film Technology

Brentwood's AccuFAS System, constructed of our PVC structured-sheet media, adds fixed-growth surface for bio-mass to provide increased biological primary or secondary treatment capacity (BOD, ammonia, or total nitrogen-removal) in a simple yet robust solution for your site-specific process goals.

Brentwood Engineered

Brentwood Engineered

Brentwood's design team draws on over 25 years of fixed-growth process experience to guide the design and application of our wastewater treatment products. AccuFAS systems are a direct result of our extensive research, development, testing, and evaluation programs:

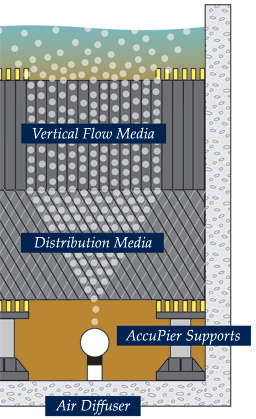

- Innovative combination of Distribution Media (DM) and Vertical Flow (VF) Media developed by Brentwood eliminates short-circuiting and provides even flow and air distribution for optimum contact between the waste stream and biomass.

- Backed by extensive pilot studies and verified continually at full-scale installations, Brentwood's process design models accurately predict treatment performance.

- Project-specific, fully-integrated physical system layout design (media, supports, diffusers) by Brentwood engineers complement overall project design.

Simple, Compact, Robust

- Simple operation without hydraulic limitation or in-basin moving parts

- Combination of DM and VF media offers a high, effective specific surface area in a compact package

- Brentwood's proven structured-sheet media and AccuPier support and retention systems ensure a 20-year-plus service life.

Lower Cost and Maintenance

- Eliminates the potential for washout of suspended media systems and the need for submerged screening

- Lowers the treatment capital cost (based on pounds of ammonia removed per day) compared to moving bed systems

- Requires no additional operational costs over those of conventional activated sludge systems

Applications

Upgrade Existing Activated Sludge Plants with Integrated Fixed-Film Activated Sludge (IFAS):

- Improve year-round nitrification and overall process stability

- Increase treatment capacity without constructing additional tanks

- Upgrade to denitrification by the MLE process in existing aeration tanks

Optimize New Facilities with a Fixed-Bed Bio-Reactor Process (FBBR) for BOD or BOD and Ammonia removal:

- Fixed biofilm eliminates all recycle sludge pumping and control requirements.

- Requires less tankage, process piping, and equipment compared with alternative treatment processes

- Simple process control and stable operation

Add Nutrient Removal to Lagoons with IFAS or Brentwood's patented Critical Velocity Submerged Anoxic Reactor (CVSAR):

- Pre-lagoon CVSAR process (above) for BOD and Ammonia removal with denitrification - no clarifier required

- Post-lagoon FBBR for polishing with nitrification

- Simple, compact, easy-to-operate, and cost-effective upgrade for all lagoon systems