Electrocoagulation: A Shocking Approach To Wastewater Treatment

By Laura Martin

Sometimes water and electricity do mix. A growing number of wastewater treatment professionals, especially those in the industrial sector, are turning to electrocoagulation — a water treatment process that uses electric current to remove various contaminants from water.

“Electrocoagulation and similar ideas have been around for years, but the technology is now gaining traction,” said TJ Mothersbaugh, the business development manager for WaterTectonics, which offers the technology.

The technology is most commonly used in the oil and gas, construction, and mining industries to treat emulsified oil, total petroleum hydrocarbons, suspended solids, heavy metals, and other difficult-to-remove contaminants. Changes in regulations and growth in those industries has brought electrocoagulation to the forefront in recent years, said Mothersbaugh.

Electrocoagulation is performed by applying an electric current across metal plates that are submerged in water. Heavy metals, organics, and inorganics are primarily held in water by electrical charges. By applying another electrical charge to the contaminated water, the charges that hold the particles together are destabilized and separate from the clean water. The particles then coagulate to form a mass, which can be easily removed.

Electrocoagulation can be used as a pretreatment for processes such as clarification, reverse osmosis (RO), and ultrafiltration, or as a polish treatment at the end of traditional treatment processes. The technology typically eliminates the need for chemical or biological additives or demulsifiers. Without chemicals, there is also no need for chemical mixing tanks.

This is appealing to environmentally concerned companies, said Mothersbaugh.

"People are looking for options other than chemicals because they are dealing with wastewater that is going to be directly released into surface water,” he said. More and more people want to protect the environment.”

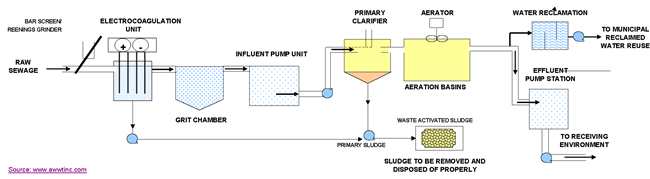

Depending on the application, electocoagulation can sometimes cut back on steps in the typical industrial wastewater treatment process, said Patricia Werner-Els, chief science officer at Advanced Waste & Water Technology Inc. (AWWT), which offers the technology.

When you set up this technology, what it does or does not incorporate depends on the goal or purpose of the water after the process is completed,” said Werner-Els. “We’ve had cases where we just had to use electocoagulation — no membranes, no settling tanks, no other steps.”

The electocoagulation process also renders the sludge inert, making it easy to remove and repurpose or reuse. The ability to recycle sludge, or even water, is the biggest benefit of electocoagulation, especially in the fracking industry, said Werner-Els.

"There is a site we are working on where they are taking the water they are using in the oil field and are able to reuse it in the drilling process, clean the water, and pipe it to a local area to use for irrigation, all by using electocoagulation," she said.

Electocoagulation can also limit the need for injection wells, which are required in traditional fracking practices to dispose wastewater below the aquifer. Using electrocoagulation, fracking wastewater can be treated onsite and used multiple times in the fracking process. The system is portable and can be easily transported from one drilling site to another.

A water recycling system using electocoagulation could also be implemented at a municipal wastewater treatment facility.

"Instead of cleaning water and releasing it back into the environment, using electocoagulation we can get the water to a level that it can be reused for irrigation for golf courses and other places like that,” said Werner-Els. “It is a much easier and cleaner way to recycle our water for reuse and to reenter it into the ground safely. We really need to think about reuse and recycling the wastewater that we can, because water is such an important resource.”

Electocoagulation systems can be designed to remediate anywhere from 100 to 500 gallons per minute to 20,000 gallons of water per minute. Electocoagulation technology is expected to have multiple applications in the coming years, said Mothersbaugh of WaterTectonics.

“Right now there are about a half a dozen companies in the United States working with this technology,” he said. “Most have focused on lower flow applications and industrial wastewater streams. But there is a lot of potential for more. Our main goal is trying to get the word out that water is a resource we want to reuse and this is way to do it.”

For more on treating industrial wastewater visit our Produced Water Solution Center