Submersible Wastewater Pumps Emphasize Reliability, Response Time And A Reduced Carbon Footprint

Chantale Lhersonneau, Sales Manager for KSB, discusses the keys to success for the Company’s global distribution of submersible wastewater pumps.

The following is an excerpt from a Q&A with Water Online Radio. Click on the Radio Player above to hear the full interview.

Water Online Radio: Tell us a little bit about you and your company.

Chantale: KSB is a German company, and our companies provide products to the industrial, municipal, and domestic wastewater sectors worldwide. We have provided a complete offering of pumps, valves, and systems for more than 30 years now.

Water Online Radio: Chantale, tell us about the standard submersible pumps.

Chantale: This product is a German make, so even if the factory is in France, we can distribute it all over the world. The barrier for America was the voltage. We now have a dual-voltage machine specially created for your market in 60 cycles.

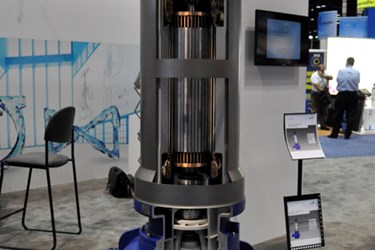

This machine is also very remarkable because of the efficiency of its vortex impeller. For security, we have a plug-in cable which prevents any water from entering the motor, so it’s safe for the user. It is epoxy filled so it is very secure. And there’s a dual mechanical seal for maximum reliability.

We designed this machine with the environment in mind and it allows for a reduction in carbon footprint. This is something which makes us proud of our company and our product.

Water Online Radio: Would you put reliability first when it comes to submerged pumps?

Chantale: Yes. Reliability is very important when you think about putting an electrical motor under the water. Our machine has a real advantage in that we built it with the least risk possible. We have only one housing that makes up the whole pump body. Most other pumps have two parts, which creates the necessity of having another gas tank in the middle.

Water Online Radio: I’d imagine that a quick response time for the customer is very, very important as well. Talk about that a little bit.

Chantale: Yes. The response time is key. These machines are meant for getting rid of a very bad situation as quickly as possible. So when a machine has something go wrong, you have to replace it fast. We store these dual-motor machines in Richmond, VA so they are available on the American market right away. Moreover, most of our representatives in the regions have started to store these machines for day-to-day business.

Water Online Radio: Chantale, I’ve heard you mention carbon footprint as a key feature of the product. What can you tell us about that?

Chantale: We want to show our customers how we do our best to protect the planet. We do this by measuring all the energy we use, as well as an estimate of the energy that the end users will use with our products. A machine like the Amerex saves energy thanks to an optimized hydraulic system that allows for higher efficiency.

Water Online Radio: It must have taken a lot of focus and planning to invest some of that German engineering you were talking about with the factory in France.

Chantale: It did. We were inspired by the very high expectations of a German company. We were the first in France to experience carbon footprint analysis on a pump company...

Click on the Radio Player above to hear the full interview.