Electrospinning & The Future Of Continuous Pharmaceutical Manufacturing

A conversation with Blair Brettmann, Ph.D., Georgia Institute of Technology

Much of continuous manufacturing’s current (if still nascent) success in the pharmaceutical industry can be traced back to academic roots. Janssen’s well-publicized switch from batch to continuous production for Prezista was facilitated by work conducted at the Center for Structured Organic Particulate Systems (C-SOPS), headquartered at Rutgers University and run in partnership with the New Jersey Institute of Technology, Purdue University, and the University of Puerto Rico at Mayaguez. The processes implemented at Novartis’ Continuous Manufacturing Facility were developed on the campus of the Massachusetts Institute of Technology (MIT).

Many more continuous manufacturing advances are on their way to industry from universities around the world. One interesting example can be found at the Centre for Continuous Manufacturing and Advanced Crystallisation (CMAC), based at the University of Strathclyde in Glasgow, Scotland. Other promising work is taking place at the Georgia Institute of Technology. Water Online recently caught up with Blair Brettmann, Ph.D., assistant professor in Georgia Tech’s School of Materials Science and Engineering. Brettmann did her doctoral work at the Novartis-MIT Center for Continuous Manufacturing, and is building upon that research to develop a drug production system that can scale up for broader commercial use. In this Q&A, Brettmann discusses the current state of continuous manufacturing in the pharmaceutical industry, her group’s research into electrospinning and other novel approaches, and how to overcome the challenges to further adoption of continuous processes.

What were some of the most important lessons you learned during your time at the Novartis-MIT Center for Continuous Manufacturing?

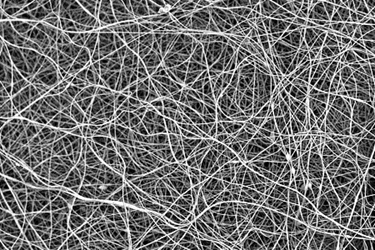

I started my Ph.D. when the MIT-Novartis Center had just begun and was one of the first graduate students involved in the project. My work was part of the downstream team, working to convert purified drug to a final dosage form in a continuous manner while minimizing solids handling. Many Ph.D. students and post-docs were focused on this section, following approaches from film formation to hot melt extrusion to electrospinning, which was my particular technology focus. The organizational structure of multiple approaches operating in parallel was critical to our success, both for having more openings for a “win” and for providing opportunities for learning from one another during the stages of development. For example, my work examining the extent of mixing of amorphous drug and polymer excipient following electrospinning using solid-state nuclear magnetic resonance was subsequently used to analyze hot melt extrusion and compare the two manufacturing technologies. The team-focused culture played a strong role in our success, as we frequently interfaced to share information and creatively overcome problems together.

I started my Ph.D. when the MIT-Novartis Center had just begun and was one of the first graduate students involved in the project. My work was part of the downstream team, working to convert purified drug to a final dosage form in a continuous manner while minimizing solids handling. Many Ph.D. students and post-docs were focused on this section, following approaches from film formation to hot melt extrusion to electrospinning, which was my particular technology focus. The organizational structure of multiple approaches operating in parallel was critical to our success, both for having more openings for a “win” and for providing opportunities for learning from one another during the stages of development. For example, my work examining the extent of mixing of amorphous drug and polymer excipient following electrospinning using solid-state nuclear magnetic resonance was subsequently used to analyze hot melt extrusion and compare the two manufacturing technologies. The team-focused culture played a strong role in our success, as we frequently interfaced to share information and creatively overcome problems together.

A critical aspect of the project was the focus on broad applicability in the pharmaceutical industry. Through frequent meetings with Novartis representatives, both in person and by phone, we had the opportunity to ensure we developed technologies that were useful not only for certain drugs or lab-scale tests, but for a broader goal of manufacturing all drugs continuously. This invaluable input pushed me to expand the use of electrospinning to producing crystalline drug products, which had not been done previously and has led to further research in my group at Georgia Tech. The focus on broad applicability is essential for technologies such as continuous manufacturing that require capital equipment and aim to transform the industry.

A final aspect of my work there was the balance of practical application with fundamental understanding. At every step in the project, we built on our initial experimental results that tested the technology to develop a strong base of fundamental understanding of how the manufacturing process itself impacted final product properties. In my work, this included examining the effect of particle size, particle density, and particle loading on the electrospinnability of drug crystals and developing simple models to describe the process. This approach resulted in a bulk of knowledge that is invaluable when moving towards scale-up and implementation.

How would you characterize the current state of continuous manufacturing in the pharmaceutical industry?

After my Ph.D., I spent 2 years at Saint-Gobain as a research engineer in polymer processing. An important difference I noticed between polymer processing in industry and developments in continuous pharmaceutical manufacturing is the wide process knowledge gleaned from years of history with polymer processing. From both an R&D and operational standpoint, there is significant experience with operations such as melt extrusion, injection molding, and solution deposited coatings that rapidly speeds up product development and is lacking in the pharmaceutical industry for continuous processes. This is not an insurmountable problem, as many of the “new” processes are derived from those of other industries, but significant cross-pollination is essential to rapidly develop a knowledgeable workforce and ensure that scale-up and manufacturing challenges can be addressed.

An advantage to entering the continuous manufacturing space at this time is the ability to integrate advanced online measurement, analysis, and process control. This is stronger in the pharmaceutical industry than in polymer processing, both due to strict regulatory controls and to the ability to integrate new advanced technologies that were not available when many plastic plants were constructed. This not only provides better control of processes and products, but, when combined with modern data analytics techniques, also has the potential to highlight correlations between materials, processing conditions, and properties that are not seen on the lab scale. This may lead to deeper process understanding and even guide R&D efforts as new patterns are identified.

What are the main hurdles preventing faster and more widespread adoption of continuous manufacturing?

Batch processing has advantages for specialized, small-scale production of drug products, and these advantages hamper the adoption of continuous manufacturing by limiting the number of drugs for which it is suitable. Further developments in flexibility and customization of continuous manufacturing processes are critical to expanding their use beyond blockbuster drugs. Approaches such as the Pharmacy on Demand funded by the Defense Advanced Research Projects Agency (DARPA) at MIT — which could manufacuture 1,000 doses of one of four drugs in 24 hours — lead in the direction of greater customizability and flexibility.

From a scientific perspective, a lack of detailed understanding of molecular-level behavior of drugs and excipients during continuous manufacturing is a major hurdle to widespread development. The sensitivity and precision necessary for acceptable production of drugs means that molecular effects — such as extent of mixing, intermolecular interactions, and mechanics of the components under flow — will play a role in whether the product meets specifications. Being able to predict these effects through modeling or lab-scale experiments, as can be done for many batch processes, is essential to rapid product development for continuously manufactured drugs. As was evident from my time at the MIT-Novartis Center, it is essential to do these studies under an umbrella that integrates applied industrial problems with fundamental knowledge and encourages frequent exchange.

Please tell us about your current research in this space. How does it address the industry’s current challenges?

My group at Georgia Tech focuses on molecular engineering for product development, tackling challenges in how molecular level behavior affects processing and product properties across a wide range of industrially relevant applications, including pharmaceuticals, energetic materials, and paper manufacturing. The overall aim is to develop knowledge that leads to predictive capabilities for complex processes or formulations, reducing the need for trial-and-error experimentation and speeding up product development. In continuous manufacturing of pharmaceuticals, we focus on downstream processing, specifically examining how drugs and excipients interact to impact processability and final drug product properties. By tuning these interactions, we can then design customized formulations for different drugs, loadings, or even continuous processes. We have capabilities for film formation, electrospinning, 3D printing, and hot melt extrusion, and I bring together my experience in both pharmaceuticals and the polymer processing industry to make an impact in this area.

What should industry be doing to accelerate continuous process and technology development?

Strong team formation is an important way to accelerate the continuous process and technology development, especially in this case, where institutional knowledge exists in other industries and universities are well-posed to contribute advanced understanding of materials and molecular behavior. Partnerships combining industry and academics are particularly fruitful when both have a vested interest and communicate frequently. Additional viewpoints can be brought in from other industries through academics or partnerships with other industries themselves.

As progress towards continuous manufacturing ramps up, it is especially important to continue support for fundamental studies so as to not outpace the ability to move towards rational design. In downstream manufacturing, this can be support for construction of structure-processing-property-performance maps for different types of drug products and materials, and for foundational studies on molecular interactions between drugs and excipients under processing conditions.

What do you see as the most important next steps for continuous manufacturing?

In downstream processing, many excellent options exist for continuous processing technologies, but rigorous studies of structure-processing-property-performance correlations as they relate to pharmaceutical products are necessary. Detailed maps of these correlations will allow rational design of pharmaceutical products and speed up scale up and product development, which is essential to wide adoption of continuous processing. Additionally, this will enable flexible and customizable formulations using the same equipment, which is a core goal of the next steps in my research group.