WATER MEMBRANES RESOURCES

-

Hauling wastewater is one of the most expensive and least sustainable means of managing wastewater, significantly impacting the environment through carbon emissions, and drastically increasing operational costs. As industries strive to meet environmental and economic goals, finding sustainable wastewater treatment methods is needed — now more than ever.

-

Per- and polyfluorinated substances (PFAS) continue to dominate the conversation as an emerging contaminant of concern due to their potential for adverse human health effects and continued regulation. This group of chemicals can be found in a wide variety of consumer products and drinking water.

-

Desalination plants across the globe are turning seawater into fresh drinking water. Yet this solution is not as simple or flawless as it sounds. The process has its own set of hurdles, such as high costs and environmental impacts. So what makes us keep chasing after desalination despite the challenges?

-

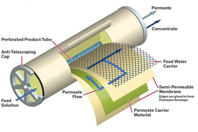

In the realm of advanced filtration technologies, spiral membranes have emerged as a revolutionary solution, transforming the landscape of various industries. These innovative membranes, characterized by their unique spiral-wound configuration, offer enhanced efficiency and versatility in separation processes. This article delves into the principles, applications, and advancements that make spiral membranes a cornerstone in the world of filtration.

-

Ever gazed at the vast expanse of the ocean and thought, "How to desalinate seawater using reverse osmosis? Can we really convert this seemingly endless source of saltwater into freshwater?" The answer is a resounding yes!

-

New electronic devices, electric vehicles (EVs), or other cool technologies bring us delightful conveniences, but they also induce some headaches. Metal wastewater streams, a byproduct of the manufacturing processes of microelectronics, EVs, and a whole host of other industrial processes, are no different and pose their own challenges.

-

Membranes have long been proven effective for a variety of applications, but certain other applications pose difficulties for the technology, mostly due to O&M concerns. Next-generation membranes, however, have the ability to overcome traditional challenges — just in time to meet requirements for greater contaminant removal and sustainability.

-

Global water usage has increased multifold over the recent decades due to various factors, including consistent population growth, changing consumption patterns, and fast-paced economic growth.

-

This white paper will explore how the BiTurbo, a revolution in high recovery RO, optimizes membrane performance and reduces total cost of water.