Siemens Industry Inc. is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years.

As one of the world’s leaders in industry automation and an experienced provider of integrated technologies, we offer products and systems tailored to the requirements of the water and wastewater industry.

The Process Industries and Drives Division can support you in continuously improving the reliability, safety, and efficiency of your products, processes and plants. We can thus help you measurably increase your productivity and improve your time-to-market – with innovative, integrated technology across the entire lifecycle.

Whether your role is engineering, operations, plant maintenance, or even plant management, we offer tailored information to fit your needs. Learn from our vast experience about up-and-coming trends in industry standards as well as innovative technologies such as web-based process control, digitalization, integration of smart instrumentation, remote monitoring and support, and more. Walk through our showcase of process measurement and control solutions and use the pop-up boxes to better understand the available choices. Let your fingers do the walking as you mine down to the information that‘s most important to you.

Take a virtual tour today: usa.siemens.com/solutionscenter

|

|

|

||

|

The Cost Of Water: Leak Detection, Economy Pumping And Dosing |

||||

CONTACT INFORMATION

Siemens Process Instrumentation

2060 Detwiler Road, Suite 111

Harleysville, PA 19438

UNITED STATES

Phone: 800-365-8766

Fax: 972-522-4503

Contact: Sales

FEATURED ARTICLES

-

In this webinar learn lessons on delivering value from digital solutions and AI from groundbreaking advancements in automotive, oil and gas and what they can mean for water.

-

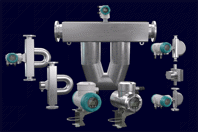

Siemens USA is pleased to announce that we have released our fully upgraded and expanded SITRANS FC Coriolis Mass Flowmeter portfolio. With this release, we have significantly enhanced our offering and capabilities.

-

Join us as we discuss the mechanism behind water hammer, its causes, and ways to prevent it from happening in the first place.

-

Discover why Siemens is your one-stop-shop for process automation, instrumentation, analytics, and weighing technology.

-

There has been no shortage of studies, discussions and debates surrounding the concept of energy efficiency over the past 40 years. Scientific studies suggest a relationship between greenhouse gas emissions and global climate change, strengthening the belief that human activity was harming the environment.

-

You can't manage what you don't measure. Learn how you can take energy efficiency to the next level.

-

Explore how utilities can deal with non-revenue water, or water that has been produced and is lost before it reaches the customer.

-

A range of devices are required to cost-effectively manage the lifecycle of produced water. Operators often face the question of which process instrumentation is the right fit given the unique requirements of their application.

-

The following article highlights four key advances in Coriolis flow measurement’s journey from the 1970s to today.

-

Easy, fast, and reliable valve control is essential to the smooth and reliable operation of your process.

-

Liquid, slurry, or solids measurements? Dirty applications? These maintenance-free sensors deliver the reliable performance you need, no matter what the environment.

-

Because no single technology can address all industrial needs and challenges, Siemens offers a full range of contacting and non-contacting instrumentation for continuous and point level measurement.

-

Discover a best-in-class solution for straightforward flow monitoring of liquid processes in number of industries, including water and wastewater, HVAC, power and chemical.

-

Learn how a municipal water treatment department reduced annual maintenance costs by $265,000, while forecasting an ultimate savings of up to $3 million in yearly non-revenue water losses.

-

Learn about an easy-to-install system that works in conjunction with a variety of heavy duty motion sensing probes.

-

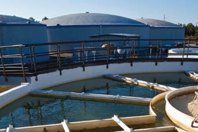

With millions of liters of water treated, accuracy and reliability are a necessity for a municipal water system. Learn about the instruments that they use to meet their needs.

-

A municipal water district had questioned the accuracy of their water meter readings and, after testing, they found that the billing amounts were too low. Discover the solution that they chose to provide reliable flow rate measurement.

-

Learn about a municipal wastewater treatment facility located in Louisiana that was having problems with its clamp-on ultrasonic flow meter, and how the issue was resolved.

-

Explore some of the most common beliefs currently being sold about radar in the environmental market.

-

A county water authority in the Northeast U.S. supplies over 40 million gallons per day to its 340,000 residential customers. In this case study, learn why they chose Siemens pressure transmitters.

-

Learn why the accuracy of the Coriolis sensors is better than any other insitu measurement technology.

-

This article will focus on the pump control functionality of advanced level controllers and how they can help to optimize your process.

-

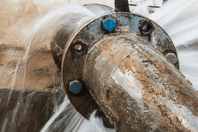

In municipalities, approximately 6 billion gallons of water are lost to leaks every day. In this article, discover a solution to water loss and excess energy costs.

-

Siemens proudly announces its expanded support of The Water Tower by becoming a sustaining partner.

-

When it comes to project execution, having quick access to equipment can make or break your success.

-

The term Digitalization is thrown around all the time in today’s work environment. With people still working remotely, reduced maintenance and support budgets and the ever-present pressure to improve performance and reduce downtime, digitalization offers some real advantages. However, with these advantages comes concerns. Concerns about cloud security, susceptibility of networks to outside access and making sure only the proper people see the specific information they should. These are key questions that are being asked and deserve to be answered.

-

Water hammer, which can occur in just about any pumping system and even steam systems, can lead to pipe breakage, equipment damage or even total system failure. Addressing water hammer at the source is the savviest and most cost-effective way to handle the issue.

-

Any process plant constantly generates a high volume of status data. Today, this data can be extracted from the plant, stored, analyzed, and prepared to meet operator needs and lower marginal costs.

-

Process automation is the eyes, ears and heart of every plant: it measures, analyzes, regulates and controls industrial processes to increase efficiency and improve product quality – helping you stay competitive and profitable despite ever-increasing demands.

-

Fully featured, advanced pressure transmitters require competitive lead times to go with them. Siemens’ North comprehensive local stock means that we have the right transmitters for you, whenever you’re feeling the pressure.

-

After years of relying on an inflexible tracking process, A.P. Nonweiler introduced cloud-based remote monitoring technology to increase inventory transparency, save valuable man-hours, and minimize the risk of costly shutdowns.

-

Level controllers have evolved to meet today’s environmental challenges and industry demands. Learn how they support improved process management and, ultimately, a better bottom line.

-

Updated with new interactive features, videos, customer stories, and more, the Siemens Virtual Process Automation Solutions Center allows you to walk through the world of process measurement and control solutions – without ever having to move your feet. Hear directly from our experts about up-and-coming trends in industry standards as well as innovative technologies such as web-based process control, digitalization, integration of smart instrumentation, remote monitoring support, and more. Navigate around the room and click on the pop-up boxes to focus on the information that’s most important to you.

-

The SITRANS FS290 is a portable ultrasonic flow meter system for remote monitoring of volumetric flow in pipes. The system is made up of the SITRANS FST090 battery-operated transmitter and SITRANS FSS220 clamp-on transducers. The transducers are installed quickly and easily on the outside of a pipe – without any process interruptions or plant downtime.

-

Manufacturers around the world are being forced to do more with less, as they grapple with finite resources and numerous challenges. The chemical process industries (CPI) in particular are facing challenges as they look to increase productivity. Digitalization and automation are game changers that can help to overcome obstacles, but they come with their own set of challenges.

-

There are many reasons to verify the performance of your SITRANS FM electromagnetic flow meter. Whether you need to ensure that the meter’s accuracy complies with local agency requirements, provide a customer with a certificate of verification for billing purposes, or simply perform some troubleshooting, the SITRANS FM magmeter family provides options for both internal verification or independently certified external verification.

-

Siemens Process Instrumentation brings you innovative measurement solutions to increase plant efficiency and enhance product quality, including flow, temperature, pressure, level, weighing, and valve positioning. And we understand that in the process industry, every second counts – which is why we offer world-class engineering, testing, and production directly from our 183,000 ft2 state-of-the-art manufacturing facility in North America. Your production doesn’t stop, so why would we? Siemens delivers the instruments you need and the reliability you depend on, with same-day shipping and service available 24 hours a day, 365 days a year.

-

Even as cyber threats increase in scale and frequency to critical infrastructure sectors, the water industry shows a varied level of preparedness from one utility to the next. Implementing an effective cybersecurity program is both necessary and achievable. We've gathered industry leaders and technology experts to examine the current state of cybersecurity in the water sector and share practical advice on securing your facility against threats.

-

There’s a lot to be considered in the price tag of an ultrasonic instrument. Derek Moore from Siemens explains how the historical way of thinking only of capital costs needs to change to the more holistic approach of total expenditures.

-

The addition of the Siemens SITRANS store IQ hardware solution and app allowed Decatur immediate access to flow rate, totalizer, and head measurement on all their devices.

-

The Saalfeld-Rudolfstadt Association in Germany must rely on cutting-edge technologies that optimize flow measurement in order to allow for smooth processes and supply 82,000 inhabitants with clean drinking water.

-

When it comes to level instrumentation, one technology definitely does not fit all. Assuming you can use the same level device to meet every measurement need is unlikely to yield optimal results for your processes – or your bottom line.

-

In this on-demand webinar join Eric Heilveil of Siemens Industry Inc., as he discusses a new advance in custody transfer flow measurement for the gas industry, that delivers critical accuracy with a very low cost of ownership.

-

Control valves are critical components in almost every process, and one of the most expensive. Between the compressed air driving your pneumatic actuators and the regular maintenance on the valve assemblies themselves, many factors contribute to the continual costs of keeping your process up and running.

-

Martin Dingman of Siemens Process Instrumentation will discuss the new FS230 clamp-on ultrasonic meters for liquid and gas hydrocarbon flow measurement. Topics to be covered are theory of operation, innovative features and benefits, liquid and gas hydrocarbon applications, installation tips and tricks, and selection criteria.

-

To increase the reliability of field devices, some manufacturers equip instruments with internal verification functions based on integrated hardware components. Procedures for the internal testing of devices are not new to the market, but rather a standard feature – at least for MID (European Measuring Instrument Directive) devices. This article looks at the advantages and disadvantages of advanced integrated verification functions for electromagnetic (MAG) flow meters with advanced integrated verification functions compared to external verification.

-

If your head spins after reading how amazing one level measurement technology is in comparison to another, understanding the key attributes of these technologies and their applicability to specific processes may help to clear the waters.

-

A power plant plant experienced an accident when a pipe broke after it was sand-dusted during maintenance. The pump location, including the turbines and control room, was completely flooded. Read about the customer's search for a cost-effective flow measurement solution to drive a safety shut-down valve in case the pipe should break again.

-

A utility company in the Pacific Northwest region of the United States needed to regulate the outflow of a large dam built in the 1930s. The outflow of the dam feeds a river into which the state government wanted to reintroduce a salmon run. Because of this, the utility company would need to comply with some very restrictive limits on how quickly they could change the level of the river. They were now required to account for all water flowing downhill from the dam.

-

When an energy storage facility in New York, USA was looking for a way to improve the efficiency of their power generating turbines they did not have many options to choose from. Because of the sheer size, the space limitations and performance requirements of the application, the only option was to install a SITRANS FS230 clamp-on ultrasonic flow meter from Siemens.

-

A suburban township in the upper Midwest United States buys their drinking water from a major municipal water district. The township’s water distribution system network has four connections to the larger municipality’s water transmission main. The municipality has many wholesale customers and has implemented contracts with each customer to limit the peak flows and the time of day in which they may occur. If a customer exceeds the limit, they are assessed significant surcharges.

-

Siemens offers to our customers the ability to make both process measurements, and to remotely monitor the activity and health of instrumentation, whether you have a SCADA, PLC or DCS system, or not. By utilizing Siemens’ ability to offer unparalleled flow, level, pressure, temperature, and weight measurement we can provide a broad range of process measurements and offer unequaled monitoring of the health and performance of those products.

-

Your water treatment facilities and water distribution networks are a complex set of interlocking steps that should include making the measurement, protecting that information in the cloud, and then putting it in the hands of key personnel, regardless of where they may be. This is the challenge of the 21st century — extracting needed information and getting it to the right people. This is where digitalization comes in.

-

For 30 years, the HydroRanger 200 has been the industry standard for level measurement in water/wastewater monitoring and pumping, inventory management, truck load-outs, open channel monitoring, and anything in between. The HydroRanger 200 gives you unparalleled ease of use, setup in under a minute, customer-driven features, and PROFIBUS DPV1- all to make your work simpler and to provide the reliability you have grown to trust in Siemens ultrasonic controllers.

-

A West Coast wastewater management facility provides design, management, and maintenance of the sanitary sewer system for an entire county, including the conveyance system and treatment system. The wastewater treatment plant has been established for over 50 years and has the capacity to treat 41 million gallons of sanitary sewage per day (mgd).value chain. Siemens suggested that the customer try the Siemens HydroRanger 200 controller. The HydroRanger 200 uses proven, continuous, ultrasonic echo ranging technology to monitor water and wastewater of any consistency up to 15 m (50 ft) in depth.

-

Siemens Process Automation is proud to announce the opening of a state-of-the-art technology showcase and demonstration center in the greater Philadelphia area, offering customers in the process industries a chance to experience the future of industrial operations up close, hands-on and all under one roof.

-

The water and wastewater industry has been dominated by automation based on programmable logic controllers working in tandem with SCADA. However, newer systems that better blend those aspects provide improved intelligence. As a result, plant operators aren’t required to maintain a separate engineering station to control strategy as well as the HMI.

-

The best systems are ones that are not just effective by design; importantly, they are employed to optimal effect. When it comes to treatment plant instrumentation and automation, it's essential that the volumes of data collected throughout the treatment process are easily understood and acted upon. In this video, Jack Roushey, Marketing Manager for the Flow Division of Siemens Process Instrumentation, talks about how Siemens addresses these challenges through their portfolio of process measurement and analytics systems. He discusses the advantages of digitalization, including digital twin technology, and how smart instruments can be leveraged to solve some of the industry's highest-level concerns, such as water quality and resiliency, while making it more simple than ever for operators.

-

Siemens provides the full spectrum of process measurement instrumentation for the water and wastewater industries and lays the foundation for seamless integration into the Digital world and remote monitoring.

-

How Siemens can move information from smart instrumentation to a Digital Cloud based format for protection of data. In addition Siemens can model an entire plant through a digital twin to allow what-if analysis of the facility that can not be simulated in the world. The cloud also allows for access of information through remote monitoring.