Wastewater treatment plant installs SBR system and lowers power, maintenance costs

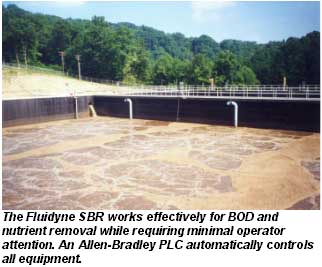

The City of Beckley, WV needed to upgrade the Piney Creek Wastewater Treatment Plant with new process equipment and technology. From a group of three suppliers, the city selected Fluidyne Corporation (Cedar Falls, IA) to provide a sequencing batch reactor (SBR) system. This chosen system has fixed decanters and jet aerators/mixers, and had the lowest annual power cost and annual maintenance cost when compared to systems utilizing floating decanters with fine bubble aeration and separate mixers.

The wastewater treatment plant consists of two SBR tanks each 140' x 100' x 16.2' top water level. Each SBR tank is equipped with three jet aeration headers and three 30 HP jet motive pumps. A 200 HP positive displacement blower package provides process air to each SBR. Three sets of decanters in each tank allow flexibility and redundancy while still maintaining a low withdrawal velocity of one foot per second per foot of decanter, which eliminates the concern of pulling sludge from the sludge blanket as a result of high withdrawal velocities associated with floating decanters.

The Piney Creek SBR plant currently handles a design flow of 2.25 mgd with a future peak flow of 4.5 mgd.

Plant Manager Greg White, P.E., is pleased with the performance of the new equipment. He says, "the SBR plant consistently surpasses all state effluent requirements and has handled as much as 9 mgd of flow without deterioration of effluent quality." See Table 1 for plant performance data.

For more information on this system or other Fluidyne Corporation products, visit their storefront or contact the company at 2816 West First Street; Cedar Falls, IA 50613; Phone: 319-266-9967; Fax: 319-277-6034.

Edited by Tracy Fabre

Managing Editor, Water Online