Wastewater Disinfection And Energy Generation Make ‘Hot' Couple

By Laura Martin

When the Pasteurization Technology Group (PTG) first presented their heat-based wastewater disinfection system to a group of environmental engineers, they didn’t get the response they expected.

“They literally asked us to leave,” recalled PTG CEO Greg Ryan. “Before we could explain how it works, they looked at us like we were crazy and said ‘disinfecting water with heat uses too much energy and isn’t cost effective.’”

But PTG’s system is more than cost-effective, said Ryan. It is cost-cutting.

“A plant can cut its disinfection costs by 50 percent using this system,” he explained. “And they can also cut their energy costs by 40 to 50 percent.”

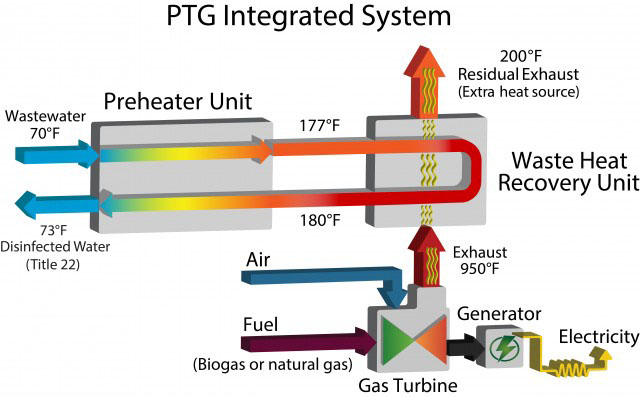

This cost savings is achieved using a combination of renewable energy generation and wastewater disinfection technologies. Biogas — a natural byproduct of wastewater treatment — or natural gas is used to drive a turbine that generates renewable energy. This energy can be used to power multiple processes at a wastewater treatment plant and significantly offset the external electricity required. However, only 30 percent of the energy created by the turbine gets translated into electricity. The rest leaves as exhaust waste heat. With the PTG system, that hot exhaust air is passed through a waste heat recovery unit and used to increases the temperature of the wastewater to around 165 degrees or higher, the temperature needed to disinfect water.

The system solves two problems at once, explained Ryan.

“The energy guys are worried about energy costs, and the disinfection guys are worried about disinfection byproducts,” he said. “Long-term this is the solution to both.”

The Water Environmental Federation (WEF) agreed, awarding PTG with the Innovative Technology Award last October.

Heat has always been an effective way to disinfect water, but the high expense of traditional heating methods prevented it from being an accepted alternative to UV or chorine.

“We believe that heat is the best disinfection out there,” said Ryan. “UV and chlorine knock down live organisms to a certain level that is acceptable. “But heat is nondiscriminatory, it kills everything, even more than it needs to. Our system is still going to be able to do an incredible job of disinfection.”

PTG’s technology has been certified by the State of California under Title 22 for the disinfection of wastewater for non-potable reuse and safe discharge. California’s Title 22 is recognized globally as one of the toughest standards for water recycling and reuse.

Although the idea behind the PTG system is new, the technology used is not.

The basics of the system include a turbine or engine, a heat exchanger, and a fan and pump to move the hot air.

“This isn’t scary new technology,” said Ryan. “We can take existing turbines and engines and design the system around that. We don’t have to build from scratch. It is about combining three or four different pieces in a new or different manner.”

The software incorporated into the system is a bit more high-tech. It allows the operators to remotely monitor the process from a tablet or smart phone, giving them the ability to make adjustments from miles away.

“If there is an issue, you don’t have to run out there — you can pop open an app on an iPad and see how many gallons of water have been disinfected and make sure everything is running properly,” said Ryan. “There is very little maintenance required.”

The PTG system has been on the market for approximately six months. The technology was utilized as part of a three-year test project at a municipal wastewater treatment plant in Ventura, CA, that disinfected 500,000 GPD gallons a day. It is scalable to nearly any size, said Ryan. The company has plans to complete a 50 million GPD gallon per day test project in Australia in the near future.

While the system can be used for any type of wastewater treatment, it is particularly beneficial for industrial customers that need to use a lot of water but are very concerned about electricity cost. PTG has identified the brewery, food, beverage, and agricultural industries as most in need of this technology. They plan to announce a partnership with a major brewery in the coming months.

Most of PTG’s customers are motivated by the financial benefits of the system, said Ryan. While these benefits are certainty important, Ryan hopes that more people will focus on the environmental impacts the technology can offer.

“Right now dollars and cents are the driver for this,” he explained. “But in the long term, we hope our customers are focused on doing a much better job environmentally by using something like this and not adding all these chemicals to the water and using all this energy.”

For more new technologies visit our Wastewater Disinfection Solution Center