Two Powerful Sidestream Treatment Technologies Battle To Be The Best

By Heidi Bauer, Bruce Johnson, and Tom Johnson

A comparison of post-aerobic digestion (PAD) and anaerobic ammonium oxidation (anammox) for sidestream nutrient removal at wastewater facilities

A sidestream is any flow stream resulting from the treatment of biosolids that is returned to the liquid treatment train. Sidestream flow streams at facilities with anaerobic digestion are targeted for nutrient removal because they exhibit relatively small flow with concentrated nutrient loading back to the liquid treatment train. Post-aerobic digestion (PAD) and anaerobic ammonium oxidation (anammox) are two sidestream treatment technologies that are beneficial for the reduction of nitrogen recycled back to the liquid stream without the need for supplemental carbon or alkalinity. However, because the two treatment options differ greatly, careful evaluation will help determine which is the most beneficial and cost-effective option for wastewater treatment facilities.

Post-Aerobic Digestion

PAD is a recently developed, advanced digestion process, where aerobic digestion is designed to follow anaerobic digestion. The most significant reason for implementing PAD is the reduction of nitrogen recycled back to the liquid stream without a need to supplement with carbon or alkalinity. Other benefits include volatile solids reduction, odor reduction, and struvite stabilization. Challenges, which have been overcome by operational controls and engineered solutions, include significant biological heat generated by the process and foam.

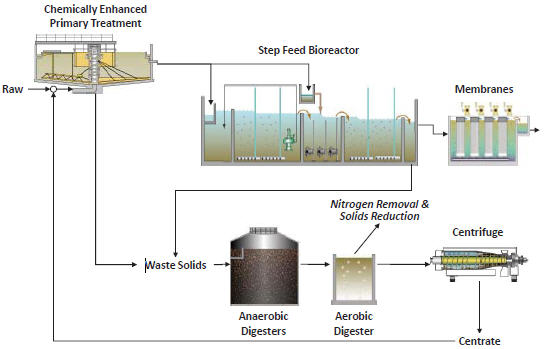

Figure 1. SCRWRF process flow diagram with post-aerobic digestion

Spokane County Regional Water Reclamation Facility (SCRWRF) implemented a full-scale PAD facility in late 2011 to help achieve strict nutrient removal, including a maximum monthly effluent limitation of 10 mg/L total nitrogen. (Figure 1)

Denver Metro Wastewater Reclamation District’s (MWRD) Northern Treatment Plant is also implementing PAD technology, which will be placed into service in the fall of 2016. The MWRD selected PAD as a cost-effective way to help achieve strict nutrient removal criteria, including a maximum daily nitrate value of approximately 10 mg/L total nitrogen, while also reducing biosolids hauling costs. Typically, MWRD hauls biosolids for 30 to 60 miles to both private and Districtowned land application sites.

Anammox

Anammox harnesses a specific species of autotrophic bacteria that can achieve partial nitritation-deammonification (or, the conversion of ammonia and nitrite to nitrogen gas) under anoxic conditions. Anammox bacteria work alongside ammonia-oxidizing bacteria under partial aerobic/partial anoxic conditions to ultimately convert ammonia to nitrogen gas without fully nitrifying and denitrifying. Like PAD, one of the key benefits of anammox is the reduction of nitrogen recycled back to the liquid stream without supplemental carbon or alkalinity. Other benefits include lower energy consumption and less oxygen compared to conventional nitrification. Challenges to overcome include the slow growth of the anammox bacteria, as well as its competition with nitrite-oxidizing bacteria.

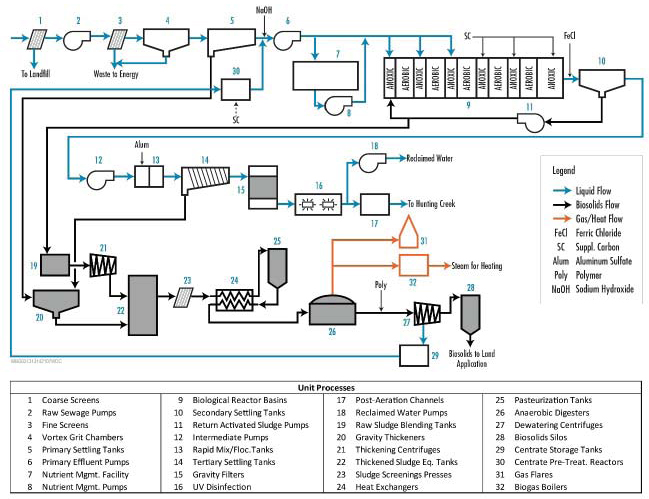

Alexandria Renew Enterprises (AlexRenew) Water Resources Recovery Facility in Alexandria, VA, is currently implementing a fullscale sidestream anammox system to help address Virginia’s state regulatory requirement to remove 62 percent of 2005 levels of effluent nitrogen by 2011. AlexRenew selected anammox technology because it can achieve significant nitrogen removal with reduced supplemental chemical addition and energy. (Figure 2)

Figure 2. AlexRenew WRRF process flow diagram with sidestream anammox

Methodology

Using CH2M’s proprietary Pro2D2 whole plant simulator tool, sidestream treatment with PAD, sidestream treatment with anammox, and a baseline (no sidestream treatment) at three hypothetical wastewater treatment facilities were compared to evaluate the respective benefits and costeffectiveness of implementing these two treatment technologies.

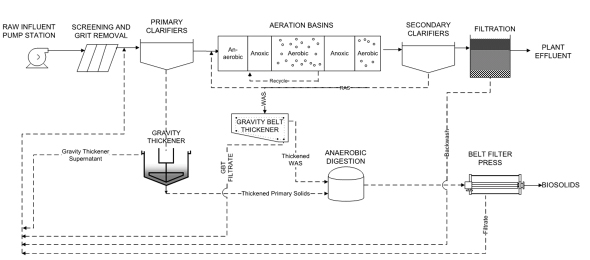

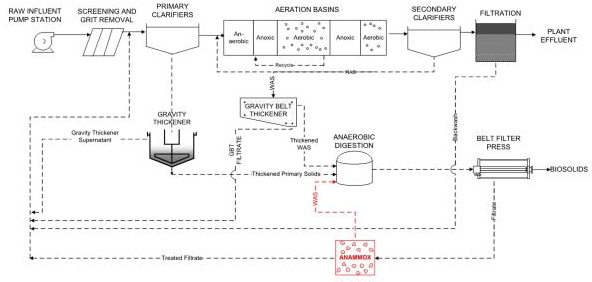

As shown in the process flow diagrams for the three models illustrated in Figures 3, 4, and 5, respectively, the PAD and anammox technologies target different sidestream flow streams; PAD targets digester effluent, while anammox targets the filtrate or centrate produced from dewatering.

Figure 3. Process flow diagram for the baseline wastewater treatment facility (no sidestream treatment)

Figure 4. Process flow diagram for sidestream treatment with PAD

Figure 5. Process flow diagram for sidestream treatment with anammox

Each model assumed a flow of 20 MGD, a greenfield site, and the same raw influent characteristics and effluent limitations, including 1 mg/L ammonia-nitrogen, 5.0 mg/L total nitrogen, and 1.0 mg/L total phosphorus.

Results

- The baseline model could not achieve the effluent limitations without supplemental carbon (1,715 pounds per day), but no supplemental alkalinity or carbon was needed for either sidestream treatment model to achieve these limitations.

- Both sidestream treatment technologies can remove a significant amount of nitrogen from the filtrate compared to the baseline (90 percent and 99 percent removal of ammonia-nitrogen with anammox and PAD, respectively) and can achieve similar effluent quality.

- Energy invested in either sidestream treatment technology results in less energy required for nutrient removal in the aeration basins (by approximately 7 percent). For sidestream treatment with anammox, the energy saved in the aeration basins overcomes the energy required for sidestream treatment.

- Considering energy use, chemical use, and biosolids production together, sidestream treatment with PAD demonstrates a net annual energy cost savings of 5.1 percent relative to sidestream treatment with anammox and a net annual energy costs savings of 19.1 percent relative to the baseline. These savings are attributed to significantly lower biosolids hauling and disposal costs due to the volatile solids destruction associated with PAD. The baseline (no sidestream treatment) offers the lowest capital cost because construction of a sidestream treatment facility costs more than the construction of a methanol feed and storage facility.

- Sidestream treatment with PAD offers the lowest annual cost primarily due to the significant savings in biosolids hauling and disposal.

- The lowest 20-year net present value is equivalent for the baseline (no sidestream treatment), sidestream treatment with PAD, and sidestream treatment with anammox alternatives.

Conclusions

Both PAD and anammox offer nitrogen removal without the need for supplemental carbon or alkalinity, but PAD should be considered when there is also a desire for additional volatile solids destruction. PAD would be ideal for facilities with high and/or volatile biosolids disposal costs or a long haul distance.

Anammox should be considered when the additional desire is energy minimization. Anammox would be ideal for facilities with high energy rates, volatile energy rates, or a desire to achieve net zero energy.

This evaluation made reasonable assumptions; however, every site is different, and different assumptions would affect the cost evaluation. For example, the assumption for a greenfield site was made in order to produce an apples-to-apples comparison, but a retrofit installation would significantly affect the cost evaluation. Moreover, if a spare tank is available, blowers, diffusers, and controls could be cost-effectively incorporated to create a PAD facility.

About The Authors

Heidi Bauer, PE, joined CH2M in 2008 and has enjoyed working on wastewater modeling, master planning, and design projects for wastewater and biosolids treatment. Prior to joining CH2M, Heidi worked as a contract operator and currently holds Colorado certifications for Class A water and wastewater, Class 3 collections and distribution, and Biosolids Land Appliers.

Heidi Bauer, PE, joined CH2M in 2008 and has enjoyed working on wastewater modeling, master planning, and design projects for wastewater and biosolids treatment. Prior to joining CH2M, Heidi worked as a contract operator and currently holds Colorado certifications for Class A water and wastewater, Class 3 collections and distribution, and Biosolids Land Appliers.

Bruce Johnson, global technology leader for wastewater simulation, joined CH2M in 1995 and brings more than 26 years of experience operating, troubleshooting, and designing water and wastewater treatment plants and equipment. He is seen as an expert in modeling and designing wastewater treatment facilities and has made a lasting impact on the wastewater profession through the high-end application of wastewater simulation to advanced waste treatment design. He holds five patents in wastewater technologies and has authored/ co-authored more than 25 technical papers on the subject. He was recently named an IWA Fellow by the International Water Association.

Bruce Johnson, global technology leader for wastewater simulation, joined CH2M in 1995 and brings more than 26 years of experience operating, troubleshooting, and designing water and wastewater treatment plants and equipment. He is seen as an expert in modeling and designing wastewater treatment facilities and has made a lasting impact on the wastewater profession through the high-end application of wastewater simulation to advanced waste treatment design. He holds five patents in wastewater technologies and has authored/ co-authored more than 25 technical papers on the subject. He was recently named an IWA Fellow by the International Water Association.

Tom Johnson joined CH2M as a Senior Technologist in 2005. With more than 17 years of experience working in the water industry, Tom specializes in wastewater process analysis, modeling and design, wastewater collection and conveyance, as well as wastewater treatment plant optimization and efficiency.

Tom Johnson joined CH2M as a Senior Technologist in 2005. With more than 17 years of experience working in the water industry, Tom specializes in wastewater process analysis, modeling and design, wastewater collection and conveyance, as well as wastewater treatment plant optimization and efficiency.