Top 10 Water Technologies From ACE14

By Kevin Westerling,

@KevinOnWater

If you were in Boston for ACE14 — the Annual Conference and Exposition put on by the American Water Works Association (AWWA) — you saw rows and rows of technologies in booths of all shapes and sizes. The exposition drew more than 500 exhibitors and approximately 12,000 attendees from June 8 to 11, and four days was hardly enough to absorb it all. I scoured the tradeshow floor for exciting and innovative technologies, but also for products that are smart, practical, and make life easier for the water professional. Here are my top 10 finds from ACE14.

EchoShore Advanced Transmission Main Monitoring

Echologics, a division of Mueller Co.

Failing pipeline infrastructure is consistently listed as one of the biggest concerns and expenses for utilities. Maintenance is typically performed continuously, a little at a time according to priority — always with the hope (fingers crossed) that pipes don’t burst before crews get to them. EchoShore by Echologics brings a level of security to utilities by monitoring the lifeblood of the water distribution system, the transmission main, with acoustic leak detection, data collection, and alerts that can be sent via email or text (SMS) messaging.

The components of the system (antenna, data logger, and hydrophone) are installed outside the pipe (see image above), easing installation and preventing disruption of service. The data is collected around the clock and presented through an easy-to-understand, web-based interface that can be integrated into existing IT infrastructure. When a potential problem is detected, users will get an immediate alert on their phone and computer screen indicating the location of the leak, thus prompting corrective action before catastrophe strikes.

HydroView Submersible Inspection Vehicle

Aquabotix Technology Corporation

Potable storage tank inspections are a sometimes overlooked responsibility, possibly because of the trouble in seeing the tank’s interior — often requiring a diver with lighting and photography equipment or draining of the tank. But new technology could make the inspection process much easier, and perhaps even fun.

The HyroView Pro is a remotely operated vehicle (ROV) that is controlled through an iPad app, a video-game-style manual controller, or set to run on auto-pilot. It is equipped with an HD camera, headlights, and sensors to detect depth, temperature, and orientation. The HyroView Pro can submerge to a depth of 330 feet, sending back pictures or a live video feed of your tank’s condition, which the EPA recommends should be conducted at least once every five years. Plus, it looks cool.

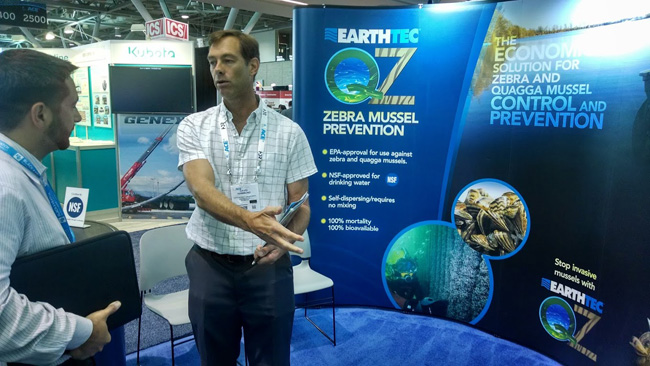

EarthTec QZ Molluscicide

Earth Science Laboratories, Inc.

If you have a surface water intake and you don’t have a quagga or zebra mussel problem, consider yourself lucky … for now. The invasive species attach in colonies to intake screens and pump station equipment, affecting water supply and equipment for both municipalities and commercial industries — particularly power generation — with maintenance and damage repair costs estimated in the billions. Quagga and zebra mussels were first discovered in the U.S. in Michigan’s Lake St. Clair in 1988, quickly proliferating throughout the Great Lakes, along the Mississippi River Basin, and beyond. They hitch their ride throughout the U.S. by attaching to vessels, releasing up to a million eggs per year in their travels. To date, one or both species are documented present in 29 states as well as the Canadian provinces of Ontario and Quebec.

So what to do about it? Earth Science Laboratories has developed an EPA-approved liquid solution, a “molluscicide,” that can be applied in lakes, reservoirs, pipelines, and raw water intakes to achieve 100 percent mortality of quagga and zebra mussels within 48 to 96 hours. EarthTec QZ has also been NSF/ANSI-approved for drinking water and can be used with no ill effects on fish or other non-target organisms. Because it is self-dispersing, there is little time and labor devoted to application — especially when compared to the time, energy, and cost involved in cleaning infested intakes and equipment.

As a bonus, the same solution reduces geosmin and total organic carbon (TOC) in source water. Geosmin is a compound associated with taste and odor issues, while TOC is a precursor for disinfection byproducts (DBPs).

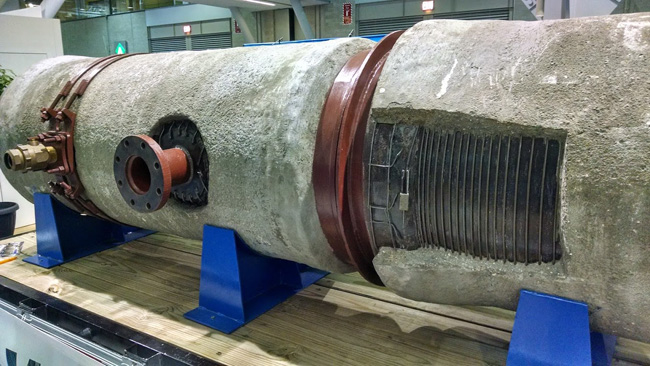

Bar-Wrapped Concrete Pipe

Speaking of proliferation — this time in a good way — a well-established pipe company is spreading out into new parts of the U.S., providing an alternative option to the infrastructure-challenged Northeast/Mid-Atlantic markets. Hanson Pressure Pipe’s bar-wrapped pipe is common throughout the Southwest and West (the company is based in Irving, TX), but was recently installed for the first time in the Northeast(ish) region — Norfolk, VA — reported Heather Meiner, Hanson’s director of marketing.

Meiner described the pipe as “the best of both worlds” — the strength of steal with the durability of concrete. Indeed, the pipe features components made of both elements: a round, “mild” steel bar is wrapped around a steel cylinder and encased in cement mortar. It is offered in diameters ranging from 10” to 72”, and costs less than prestressed concrete cylinder pipe (PCCP). It is also designed with access points for easier tapping and repair.

Each job is highly situational, of course, but bar-wrapped pipe is another tool at the municipality’s disposal. To aid in proper decision-making, Hanson offers a traveling demonstration trailer to showcase the pipe — which meets AWWA C303 standards — to interested public works managers, engineers, and contractors.

SMARTSENS Analytical Sensors

The SMARTSENS line of sensors differentiates itself by offering integrated transmitter technology — they are the only water sensors on the market that can link directly to the data logger without a separate transmitter, according to Thomas Roemer, business development manager for KROHNE. The latest in the series, debuting at ACE for the first time, is the pH/ORP (oxidation-reduction potential) sensor. The instrument comes pre-calibrated, and is designed for easy, offline recalibration. The built-in transmitter features 4-20 mA/HART communications to work with standard SCADA equipment.

Next to market for KROHNE will be its conductivity sensor, featuring the same integrated-transmitter design, due out later this year. SMARTSENS instruments are suited for water/wastewater and most industrial applications.

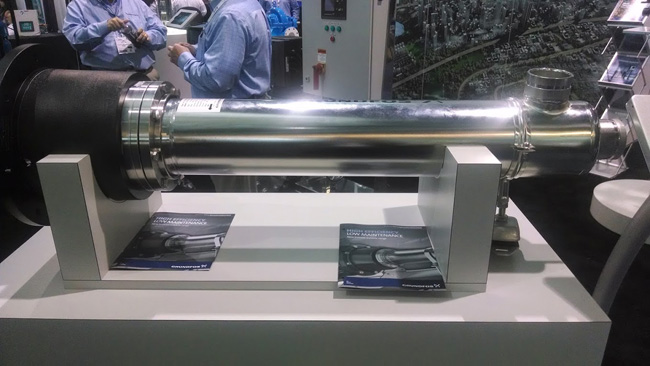

BMS Ultrafiltration Booster Module

In the realm of industrial wastewater, the hotspot is hydraulic fracturing (“fracking”) — exciting for its potential to deliver tremendous volumes of cheap natural gas, but the practice also elicits water quality and quantity concerns. Proper treatment seems to be the key to success, so that water remains safe and in adequate supply. For the latter, reuse by means of desalination/membrane treatment — reverse osmosis (RO), ultrafiltration (UF), etc. — is becoming increasingly popular (and necessary).

Grundfos BMS pumps feature a permanent magnet motor that tops out at 5,500 RPM and delivers pressure up to 1,199 psi (82.7 bar), providing both power and efficiency. New for ACE14, the BMS series optimizes efficiency with a variable frequency drive (VFD) to maintain optimal pressure at all times, also offering a pressure exchanger that converts brine into energy. It is made of super duplex stainless steel to handle brackish water applications, but has a smaller footprint and is 75 percent lighter than Grundfos’ previous-generation booster module. According to Harland Pond, the business development director for the new line, the BMS range greatly improves on O&M characteristics by providing durable operation alongside easy-to-access to maintenance points.

Hydrotec Drainage Channel

As stormwater management continues to trend as a rising concern — acknowledgement that we’re collectively dealing with “one water” — drainage technologies should see increasing deployment. Aimed at contractors and public works officials, a new trench drain was introduced at ACE by SIGMA to help intercept stormwater and runoff before it becomes an issue for sewer systems, wastewater treatment plants (WWTPs), and the environment. According to product manager Eric Moisa, the Hydrotec drainage channel is unique for two reasons: its fiber-reinforced concrete construction and its high-strength plastic composite locking mechanism.

The concrete construction is meant to match and mimic the properties of the concrete collars that are typically used with trench drains — namely the expansion and contraction that occurs in different weather — thus avoiding separation and structural problems. And while most other drainage channels are held in place by metal nuts and bolts that are prone to rust, the Hydrotec channel employs a composite locking device that allows it to be easily removed for cleaning and maintenance.

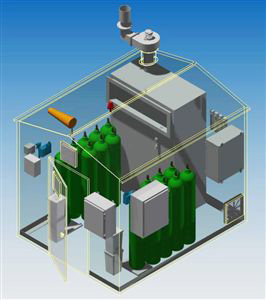

Chlorination SAFE Station

Gas-feed chlorination systems come with inherent challenges, including those related to safety, that require special consideration and equipment. Severn Trent Services has responded by introducing the Chlorination SAFE Station (CSS), an all-in-one gas feed, storage, and safety solution. The CSS is a fiber-reinforced plastic (FRP) building — 8’ wide, 10’ deep, and 11’2” high — that contains the gas feed equipment, control panel, gas detectors, scales, a 150-pound dry scrubber, safety equipment, and storage capacity for up to 15 chlorine/sulfur dioxide cylinders.

The low-profile scrubber, designed for the treatment of accidental gas releases, meets Uniform Fire Code requirements, uses non-hazardous, environmentally acceptable media, and requires no chemical maintenance. The CSS is also engineered in accordance with Chlorine Institute and Risk Management Plan guidelines.

Michael Baran, global marketing manager of water purification systems for Severn Trent, indicated that the idea behind the CSS is to provide a complete and safe gas feed installation from a single source, thereby removing the design burden from the end user.

HYMAX GRIP Restraint Coupling

Pipeline repair is a time-sensitive job, to say the least, so a coupling that offers quick and easy installation, as well as long-term reliability, is an asset for any municipality. HYMAX couplings — an existing line from Krausz USA — take “mere minutes” to install, according to the company, and have been used extensively in the U.S. and Canada. The latest development in the line, the HYMAX GRIP, was introduced at ACE14 and is designed not only for fast repairs, but also for extreme conditions.

Because of the HYMAX GRIP’s unique hydraulic sealing, the pipes can move up to four degrees at the end of each coupling, yet maintain a tight, durable seal. The grip action is achieved by incorporating universal "teeth" that can restrain all types of connecting plastic and metal pipes from 4” to 12” in diameter, actually increasing hold as pressure is applied to the connecting pipes. Installation is simplified by the coupling's “stab-fit” design and two-bolt closure. A flange adapter version of the HYMAX GRIP is also available.

End-To-End Asset Protection System

For all the treatment technology that goes into providing clean, safe drinking water, the utility’s efforts are all for naught — and public health is in jeopardy — if the water is compromised by intruders or terrorists.

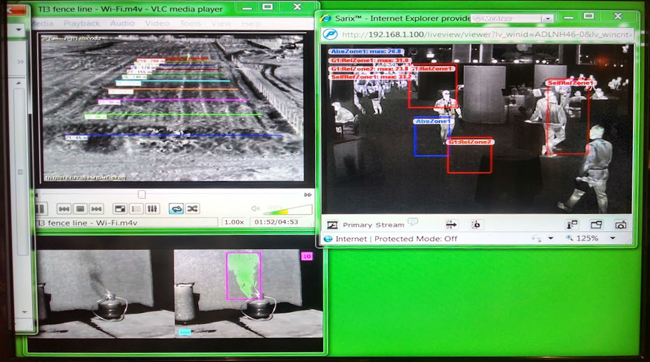

Schneider Electric offers extra security to water treatment plants (WTPs) and the community through its "end-to-end" solution, which uses thermal imaging cameras to monitor the WTP's perimeter and interior, remote pumping stations, or any critical equipment that may be at risk. The system collects heat and temperature signatures, 24/7, and continuously sends the metadata from analytics (stored on the camera) back to various types of control systems — HMI, PLC, SCADA, or VMS (video management system). By contrast, periodic physical inspections leave water supplies unwatched and vulnerable for extended periods of time.

Thermography also has the ability to handle preventative maintenance on pumping station equipment, as well as monitor tank levels. Since information is streamed continuously, trending analysis can be performed to identify when a part may be in need of repair, as excessive heat is an indicator of imminent failure. The system is also soon to incorporate a gas detection feature for an added level of security and asset protection.

For more technology solutions that cater to your specific need(s), visit the Water Online homepage and browse the top navigation.