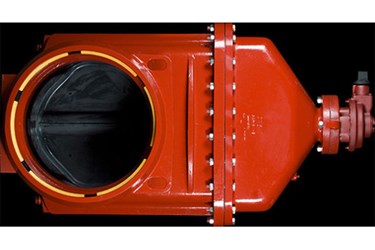

16"-60" Series 2500 Resilient Wedge Gate Valve With Flex-Ring Ends

AMERICAN’s 16"-60" Series 2500 ductile iron resilient wedge gate valves are suitable for use in potable water, sewage and fire protection systems.

AMERICAN’s 16"-60" Series 2500 ductile iron resilient wedge gate valves are suitable for use in potable water, sewage and fire protection systems. These valves have a rated working pressure of 250 psig with zero leakage. The waterway is clear and unobstructed.

The Flex-Ring design incorporates the following exclusive design features:

- Positive joint restraint

- No need for friction style restrainers

- No point loading of pipe wall

- No restraint hardware to corrode

- Additional joint deflection compared to traditional pipe joints

- Even distribution of pipeline thrust loads

- Joint restraint hardware is protected inside the valve joint

Advantages Over Standard Butterfly Valve Designs

- No disc in waterway to restrict flow or to increase pumping costs

- Allows passage of pigging devices

- Internal parts can be serviced without cutting valve out of pipeline

- 250 psig rating provides for future pressure increases over the 150 psig pressure rating typically found on most butterfly valves

Advantages Over Standard Double-Disc Gate Valve Designs

- Zero allowable leakage

- Lower torque requirements to operate valve

- 250 psig pressure rating compared to the 150 psig rating typically found on double-disc gate valves

- Fusion bond epoxy-coated inside and out

- Lighter total valve weight

- Single-gate construction. Double-disc gate valves have multiple parts that can seize together.

- Bypasses, rollers, tracks and scrapers are not needed.

Standard Features

- 250 psig rating

- Ductile iron construction

- Triple O-Ring stem seals

- NSF Certified coating

- Thrust washers

- Epoxy coating inside and out

- Zero leakage

- Optional gearing (Standard on 30" and larger)

- Ductile iron wedge fully encapsulated with EPDM rubber

- 16"-60" Flex-Ring boltless restrained joint

- Cast flats on valve body so valve stands upright for storage or during installation

- Bypass available at additional cost

Benefits

- Ductile Iron Construction

The ductile iron body and bonnet provide superior strength and allow a pressure rating of 250 psig. The strength of ductile iron doubles that provided by gray iron. This added strength and higher pressure rating are provided in a compact, lighter design. - Triple O-Ring Stem Seals

Sealing the lubrication chamber is a series of three O-Ring stem seals. The O-Rings help to isolate the lubrication chamber. - Epoxy Coating

The 16"-60" Series 2500 valves are epoxy-coated both on the interior as well as the exterior of the valve. The coating is applied after the valve body is shot-blasted clean. The coating is applied to all ferrous surfaces so that even the bolt holes and body-to-bonnet flange surfaces are fully epoxy coated. - Lifting Devices, 16"-60"

All 16"-60" valves are provided with integral lifting devices, which allow the valve to be handled without lifting it by the operating nut. - Thrust Washers

Thrust washers are located above and below the stem collar to reduce operating input torque and assist in trouble-free operation of the valve. - No Flat Gaskets

The stuffing box gasket and throat flange gasket are pressure-energized rubber O-Rings. This provides a seal without the need for excessive bolt loading as is required of flat gaskets.

AMERICAN - American Cast Iron Pipe Company

This website uses cookies to ensure you get the best experience on our website. Learn more